On the water side, DOE has a mandate to develop and enforce national minimum energy efficiency standards for any product

if significant savings can be realized in a cost-justified and technically feasible manner. During the past year, DOE and stakeholders have been negotiating a regulation for pump efficiency. That rule, now in the Notice of Proposed Rulemaking phase, would apply only to clean water pumps of these types:

- End suction, close-coupled

- End suction, frame-mounted/own bearings

- In-line

- Radially split, multi-stage, vertical, in-line, diffuser casing

- Vertical turbine, submersible

With the massive infrastructure of existing water distribution systems, the ability to increase energy efficiency comes down to a few items, including pumps and the motors that operate them. Utilities are incentivizing facilities to install variable frequency drives (VFDs) onto their motors and pumps to reduce the electrical surges caused by starting and stopping motors/pumps—which benefits the facility through reduced water hammer and lower maintenance costs.

By increasing the efficiency of the pump itself as well as the motor, accomplished by selecting a premium efficiency motor and operating that pump/motor system at constant pressure or constant flow, a VFD can help reduce the energy consumed. But how do weknow we will save energy?

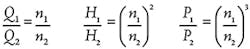

This energy consumption is due to the affinity laws; the three affinity laws describe the relationship between speed of the pump (n), flow (Q), pressure head (H), and electrical power consumption (P):

This shows us that the power to run a pump is relative to the cube of the speed, which means that if we slow down a pump by 20% we enjoy almost 50% in power or energy reduction. So, even small decreases in pump speed can result in energy savings. It is important to note that the maximum speed of the pump may not be the highest efficiency that it can pump when looking at gallons per kWh. It may be experienced at a lower than full speed flow.

But energy consumption may not be the only issue that variable frequency drives may help to resolve. What about non-revenue water? Since we can now better regulate pressure, why not reduce our system pressure?

Prior to the now common use of drives, water distribution systems typically used pressure switches to control pumps. When the system hit a low pressure point, the pump turned on, and when it hit a higher pressure point it was turned off. There might have beentwo pumps: a smaller one for slow night hours and a larger unit for the higher daily usages. This type of control causes pressure fluctuations, but is often common

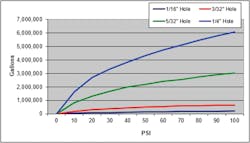

practice. With a VFD, pressure is maintained at a constant set point and, as pressure decreases, the motor/pump increases speed to maintain pressure. By reducing and maintaining a constant pressure of the system, water leakage can be reduced. For example, a single 1/4-inch hole in a distribution pipe can leak as much as 4 million gallons per year at 50 pounds per square inch gauge or over 5 million gallons per year at 80 pounds per square inch gauge. By keeping the pressure more constant, non-revenue water losses can be reduced.

While there are opportunities to reduce energy consumption and losses in water distribution systems—which could lead to higher revenue and lower operating costs—there are additional savings that may not be initially realized:

- Protection of pumps and assets

- Reduction of maintenance cost

- Limiting the risk for bacteria/contamination of tap water

- Limiting the risk for road breaks

- Reducing pipe repair cost

- Extended service life of network

- Postponing investment in system upgrades

- Improved control performance

- Increased redundancy

- Usage of dedicated VFD software features thus reduced load on the SCADA system

On the other hand, EPA, through its Clean Air Act (section 111d), will require states to develop compliance plans, which could include state energy efficiency plans. Wastewater treatment plants could be included in this. It would not likely state a minimum efficiency for wastewater pumps specifically, but could incentivize plants that reduce their energy use.

So how can wastewater operations work to increase efficiency and reduce costs today? Adding a VFD to the motor and pump can make it more efficient if it is controlled properly, similar to how in clean water applications utility rebates can help with the acquisition and installation costs. Further, the resulting lower energy bill can help to reduce the operating costs, but it’s important to be smart in the control of these systems.

For smaller facilities, using a larger SCADA system may be out of the question to operate the entire system. But today’s VFDs typically include integral controllers that can be used instead to maintain level, pressure, flow, dissolved oxygen, turbidity, or other processes being monitored. Simply by providing an analog signal to the VFD from the monitoring equipment, the VFD has the ability to maintain a constant process output, and through internal communication modules data can be transmitted to other areas to monitor current status.

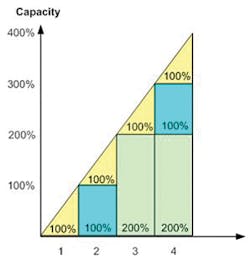

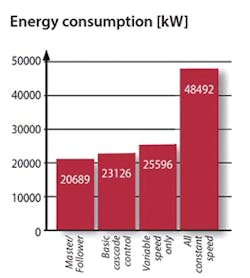

Additionally, integral cascade controllers can operate multiple pumps allowing for better overall control and—when utilized in a variable pumping system, where pumps of different flow capabilities are installed and staggered to meet flow requirements—can increase system efficiency. This type of control, master/follower, can offer the most efficient operation of a pumping system and the highest system efficiency.

In most any size system, the use of VFDs on pump motors means greater flexibility and better process control. By reducing the surges that a plant may see during an event or normal loading, the plant can more closely handle the waste influx by regulating the flows into the plant. VFDs can operate as slave units to the existing SCADA or overseeing system.

Drives can also offer features that help maintain pump efficiency such as a deragging function. This feature will rotate the impeller backwards (on a pump that can be operated backwards) to dislodge solids, stringy materials, or other debris to keep the impeller better able to pump at optimum performance.

VFD manufacturers offer different features, but drives designed specifically for the water/wastewater market tend to offer additional features to facilitate motor/pump operation such as deragging, initial ramp and/or check valve ramping, flow counting, flowconfirmation, no flow or low flow/dry pump protection, and many others. Additionally, analog and digital output cards, communication cards, and specific application cards are available to assist in control functions.

As the water/wastewater industry continues to modernize and expand—and issues like reducing energy consumption and water loss become more important and regulated, VFDs will become more commonplace in many applications.