Editor’s note: This article previously appeared in the November/December 2014 issue of Water Efficiency magazine.

Does it make sense for water utilities to integrate GIS (geographic information system) technology with hydraulic modeling? In most cases, the answer is yes.

In the past, hydraulic models were reconstructed every few years, a necessary but time-consuming process. However, as hydraulic models have increased in complexity and need to be updated more frequently, utilities are looking for more cost-effective and timesaving methods to renew these models. GIS may provide the answer.

Editor's note: This article previously appeared in the November/December 2014 issue of Water Efficiency magazine. Does it make sense for water utilities to integrate GIS (geographic information system) technology with hydraulic modeling? In most cases, the answer is yes. In the past, hydraulic models were reconstructed every few years, a necessary but time-consuming process. However, as hydraulic models have increased in complexity and need to be updated more frequently, utilities are looking for more cost-effective and timesaving methods to renew these models. GIS may provide the answer. [text_ad] Typically, hydraulic analyses, such as determination of system capacities, development of what-if scenarios, and planning of improvements have been performed independent of GIS technology. [caption id="attachment_1360" align="alignleft" width="300"]Typically, hydraulic analyses, such as determination of system capacities, development of what-if scenarios, and planning of improvements have been performed independent of GIS technology.

The GIS hydraulic water model can run scenarios for capital improvement plans, fire flow analyses, water quality, and future growth of the distribution system.

Originally, the primary function of a GIS for a water or wastewater utility was to be able to map capital assets. However, it quickly became obvious that GIS was more than just a mapping tool. When integrated with hydraulic modeling, GIS also provides opportunities for spatial analysis and data management.

“Increasingly, GIS is becoming a system of record for all assets in a water utility system,” says Joe Ball, director of marketing, water, North America, for Itron. “Integrating hydraulic modeling with GIS makes sense, because it allows both systems to share a single database. It simplifies data entry, since elevation data, pipe sizes, devices, and many other parameters are normally identified in GIS. This makes the use and implementation of any hydraulic modeling software easier.”

Ed Kura, GIS manager for Aclara, says, “It makes sense for utilities to include all of their hydraulic modeling within their GIS, because the GIS is a great place to collect this information and edit it as time goes on, so they can keep track of their network.” Kura has spent the majority of his career working on building GIS databases for water and wastewater networks, including the integration of hydraulic modeling.

“When hydraulic modeling is integrated with GIS, it provides utilities with a very powerful tool to let them know how their system is performing at the time the model is created, as well as how it should perform,” says Steve Bruskiewicz, product manager, water, for Aclara who spent almost 25 years managing water and wastewater plants before coming to the company. “Without hydraulic modeling and GIS, utilities really end up working “˜blind.'”

Are there any instances when it might not make sense to integrate the two?

“Integration of GIS and hydraulic modeling may not make sense if GIS data is not accurate or up-to-date,” says Ball. “It may be necessary to update, or even upgrade, the GIS system to make sure that hydraulic modeling software integration is effective.”

Benefits of GIS and Hydraulic Modeling Integration

Integrating GIS and a hydraulic model provides planners and technicians access to more reliable, up-to-date information, reduced response time, and accessibility of modeling elements and data.

According to Lori Armstrong, GIS and hydraulic modeling are complementary technologies. “By integrating them with each other, water utility companies can reap substantial time and cost savings,” adds Armstrong, who is global water/wastewater industry manager for Esri and author of Hydraulic Modeling and GIS (Esri Press 2011).

“A well-designed integration of the two systems provides ready access to mission-critical data,” she says. “As a result, risk-of-failure analysis, repair and replacement, capacity assessment, capital improvement planning, and other water utility applications run more efficiently and effectively.”

Integration of a GIS with a hydraulic model allows utilities to get the most from their GIS investment.

“Integrating GIS and hydraulic modeling enables utilities to quickly run scenarios for capital improvement plans, fire flow analyses, water quality, and future growth of the distribution system,” says Armstrong. It also significantly improves the ability to update and enhance modeling efforts and minimize future costs of hydraulic model development and maintenance, all while using the most correct and best data available, and limiting risk and unnecessary assumptions.

A water distribution system mapped in ArcGIS, using the World Imagery Base Map

A water distribution system mapped in ArcGIS, using the World Imagery Base Map

As Armstrong sees it, the uniting of GIS, CMMS, LIMS, AMR/AMI, and the hydraulic model creates a connected communication decision support platform that allows operators and managers to make the best, most efficient decisions about how to operate their systems.

“There is no need to maintain and update two separate systems,” says Ball. “Updating one system automatically updates the other system. It also means that no updates are required whenever models for additions or upgrades need to be performed.”

Results for “what if” scenarios can be quickly obtained, minimizing costs and maximizing efficiency. This close relationship between systems also allows for a more robust model analysis. Data can also be shared with other systems not related to hydraulic modeling.

“There are many benefits to the integration of GIS and hydraulic modeling,” says Bruskiewicz. “For one, you know where all of your assets are. They are labeled, located, and you also usually know what condition they are in, because they were physically inspected when they were added to the GIS database.”

You can also start to do water loss auditing and modeling, because you can look at the age of your system and various pressures in each zone.

“For example, if you know where your zones of high pressure are, you can estimate what your water losses will be in those zones and also estimate what your water losses will be if you reduce the pressure in those zones,” he says.

How to Get Started

According to Armstrong, leveraging a utility’s existing GIS is the easiest way to begin the development of a hydraulic model. “Because GIS manages the utility’s most current data, including the majority of data needed to develop a model, it is critical to maintain the link between the model and GIS, while recognizing inherent differences between a water system GIS and model,” she says.

“Municipalities are now moving toward modeling using regularly-updated GIS information to create hydraulic simulations, and, in some instances, even run “˜up-to-the-minute’ information from other systems,” says Armstrong. “For example, data from an asset management system can be integrated and correlated with hydraulic performance, then compared against SCADA trends to validate and respond to a field event or perform a model calibration.”

This can be done in real time. Data from the automatic meter reading (AMR)/Advanced Metering Infrastructure (AMI) system, including leaks, are sent for instant communication to field staff to investigate and respond.

According to Faheem Jalali, marketing manager, Aqualyze, the definition of the integration of GIS and hydraulic modeling can vary from one application to another. “Typically, hydraulic models are constructed using GIS databases containing physical properties of assets to be modeled,” he says.

In a wastewater system, this data will be a combination of nodes and links representing maintenance holes (MH) and pipes at the simplest level. “The GIS data will hold information such as how a given pipe is connected, i.e., node on the upstream and node on the downstream end,” he says. “Pipe and MH data, such as their sizes and invert elevations, are also contained within the GIS database.” When a hydraulic model is developed using this GIS data, the process can be automated through data import tools that are commonly available in all modeling platforms.

The definition of integration may vary at this point, depending on how a utility wants to manage its data. “Generally, it is not a good idea, in my opinion, to have a live link between the GIS and hydraulic modeling, for various reasons,” says Jalali. “For example, in most utilities, modeling falls under engineering, and GIS does not, which creates data ownership issues.”

Furthermore, he notes, modeling is a planning tool and is done interactively, evaluating many scenarios that need not be managed in GIS. GIS is a true inventory of a given system and should be kept as such.

“Different levels of accuracy are available, so it is important to determine which level of accuracy is required to ensure that all necessary data is available and with the desired level of detail,” says Itron’s Ball. “It is also important to identify which tasks can be best performed within the GIS system, and which ones can be best performed within the hydraulic modeling system. Those tasks that can be performed in either system should be identified as well.”

According to Aclara’s Kura, integration of GIS and hydraulic modeling depends on individual circumstances. “If a utility is starting from scratch and doesn’t have a GIS, it can design the GIS database to include the data they will need for the hydraulic modeling and then populate it from that point,” he says.

However, if the utility already has a GIS, it will need to determine what changes will be needed to the database. “That is, the GIS generally needs to be made to work with the hydraulic model,” he says. “It doesn’t work the other way around, because the models are usually pretty rigid.”

Challenges to Integration

According to Esri’s Armstrong, there are often pipeline connectivity issues and data deficiencies when developing a model from GIS. These challenges can be addressed through a combination of standard operating procedures, tools within the GIS and modeling software that are used to improve data accuracy, as well as protocols that can be established to allow the transfer of data corrections and modifications between the model and the GIS.

“This can be done while also allowing for a repeatable process that can be duplicated on future model updates,” she says. “More communication is also needed between the model developer, other system administrators, and GIS staff, which will improve data coordination and effective data management in order to successfully maintain a hydraulic model.”

“Hydraulic modeling is a way to analyze system capacity and future needs,” says Jalali. “The source data of any model should be reflected the same in both platforms, and can therefore be considered integrated.”

Additional information, such as modeling results under various scenarios, can be provided back to the GIS system. This requires close coordination between engineers/modelers and the GIS data management staff. Challenges can be posed by how various departments are structured within a utility, by communications and data sharing between departments, by read/write access to databases, by integrating modeling analysis results from third parties such as consultants, or by design of data schemas to hold or link GIS and modeling information.

“The key to overcoming these challenges is to define objectives, to document and follow protocols and guidelines, and to ensure close coordination and communication between interested parties in a given utility,” says Jalali.

According to Itron’s Ball, GIS data may not be accurate enough for the hydraulic model to develop useful data. Examples of this data include pipe diameters, pipe length, and elevations.

“Periodic model updates and maintenance of the databases are paramount,” he says. “Ongoing maintenance work, pipe replacement programs, and changes in demand require updates to the hydraulic model to ensure accuracy.”

To overcome these challenges, thorough preparation work is required. “The utility needs to make sure that hydraulic modeling software and GIS used, or planned to be used, are compatible,” says Ball. “The utility also needs to make sure data in GIS is up-to-date and accurate–that correct information is available, that no duplicates exist, et cetera.” Data in GIS needs to be complete and accurate enough for use with hydraulic modeling.

GIS and Hydraulic Modeling Integration in Action

One government agency that has had significant success integrating GIS and hydraulic modeling is Moore County (Carthage, NC). In fact, its integration of GIS and hydraulic modeling won the North Carolina GIS Award (G. Herbert Stout Award) in 2013, as well as the North Carolina IT Award (Government Innovation Grant Award) in 2014.

The initial motivation for creating the GIS hydraulic water model was the GIS Department’s recognition of the costs of the existing procedure–contracting out hydraulic water model requests to engineering firms. These contracts proved costly because the engineering firms would often need to recreate a water model and would only do so for the area of concern. There were also many assumptions made by the engineering firms in creating these water models in order to produce hydraulic estimates for design work.

“The Moore County Public Works Department never had a model that represented the entire system,” says Chris Butts, GISP, PLS, the GIS coordinator and interim IT Director of the Moore County GIS Department. “It was very difficult to understand where system improvements could be made. It was also difficult to know what system improvements needed to be made for long-range planning.”

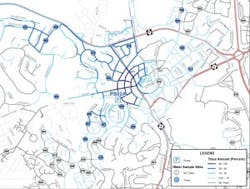

The GIS Department realized that it could create an in-house hydraulic water model that would use its high-quality utility data for the network. The vision was to create a hydraulic water model for the entire Moore County-maintained distribution system. This model could then be continued as part of the GIS utility data maintenance program. The GIS Department also obtained model parameters from the Public Utilities Operation Manager in order to decrease the assumptions that were made in previous water models. The GIS hydraulic water model could then quickly run scenarios for capital improvement plans, fire flow analyses, water quality, and future growth of the distribution system.

Water and Sewer Networks mapped in ArcGIS, using the World Topographic Map

The first task before a hydraulic water model could begin was to have accurate utility GIS data. This was accomplished by scanning all record drawings related to utility information and georeferencing them. These georeferenced record drawings were then used to update the GIS data and to serve as a reference for Public Utility staff, so they could quickly pull up a digital record drawing. However, some of these record drawings were very old, and there had been improvements and maintenance done that were not recorded. This is why it was important to field-verify the utility information. This was mostly done using handheld Trimble GPS units with TerraSync and ArcPad, which allowed customized data dictionaries for easy cataloging. Where elevation data was needed, a more precise survey-grade GPS receiver was used equipped with RTK (real-time kinematic).

“Making sure the network topology was correct in GIS was critical in having the hydraulic water model run successfully,” says Butts. “We were able to use many automated tools within GIS to check for network connectivity and errors.”

The next step was to obtain a water modeling software. The Moore County GIS and Public Utilities Department requested the help of the North Carolina local government community to see what others were using with GIS and how satisfied they were. It was then decided to use the Innovyze product, InfoWater, which offers a fully integrated water distribution modeling software application. They also offered onsite training, so staff could fully understand the intricacies of the modeling software.

The next step was to obtain practical data about the distribution system on an operational level. This meant identifying and describing wells, tanks, booster stations, and water sources. Gathering information about pump controls, pump curves, tank volumes, well depths, and such was essential in understanding how the distribution system operated, so these same parameters could be used to control the model. Water billing data was joined to address data, to determine where to allocate demand in the model. Most models will give ballpark estimates on water demand, but the Moore County GIS Department wanted to be as accurate and detailed as possible.

The next phase was to create the hydraulic water model using the existing GIS utility data. Before this could be done, network validation was used to check for any possible errors within the network, using ArcGIS Network Analyst. Tools from Innovyze were used to import the GIS utility SDE (spatial database engine) data to a model database that could be viewed within ArcGIS. Operational distribution data was then used to control the flow of water through the water model network. The final step was cleaning up any hydraulic errors that were preventing the model from having successful runs.

Once the model was running, the next step was to make sure that it was producing results that matched the real-world distribution system. This was done by comparing fire flow tests that were conducted by the Public Utilities Division with fire flow analysis results from the model. Variables were changed to calibrate the model, such as the pipe roughness coefficient, which is affected by pipe age, water quality aggressiveness, and solids depositing in the pipe. The more solids depositing in a pipe, the smaller the diameter becomes, which limits the flow of water. Initially, this coefficient was assigned by the age and material of the pipe, but it was changed during the calibration based on actual field measurements.

The next phase was to create an extended-period simulation so that the distribution system could be monitored through an interval of time. Applying average and maximum day multipliers to the system allows one to see how the distribution system could be viewed on an hourly basis. The hydraulic water model was not only constructed to report existing conditions, but also for long-range planning.

The benefits have been many. Having a GIS hydraulic water model allows Moore County to plan improvements and design, as well as better operate and manage a water distribution system. This allows for optimal water distribution performance concerning hydraulics, water quality, and future growth. Not only has this increased the water quality and efficiency of the water distribution system, but it has also been a cost-savings measure for the residents of Moore County. The hydraulic water model has strengthened the GIS enterprise and has enhanced effective communication between county departments.

In addition, the Public Utilities Division now has an accurate model portrayal of its system. It can more effectively manage capital improvement plans of the water distribution system, while making smarter decisions. It has also allowed for better and more informed communication between the Public Works Director and the Utility Operations Manager when gaining an understanding of the distribution system. The Public Utilities Division is now able to run as many scenarios as they see fit, as well as analyze any location in the distribution system, looking at a variety of factors. The Public Utilities Division has benefited financially by not having to outsource the modeling work. It has been able to change the direction and scope quickly on an as-needed basis.

“We were able to develop a 10- and 20-year water distribution plan for Moore County,” says Butts. “The GIS water model allowed us to review several water source ideas and then estimate the cost for each of these plans. This gave our Board of Commissioners a thorough review, and they were able to make a better decision based on the information the water model provided.”