Guest Commentary: Advanced Validation Method for UV Wastewater Disinfection

Ultraviolet (UV) light disinfection is one of the fastest growing technologies in water and wastewater treatment. This is due to many factors, including UV’s operational advantages over chemical disinfection options and its ease of operation and maintenance. UV light has the ability to inactivate pathogenic microorganisms within seconds. In addition, UV does not create or release carcinogenic byproducts into the environment.

However, unlike chlorine, ozone, and other chemical disinfectants whose dose can be quantitatively determined by a CT value, determining the UV dose is not so simple. Until relatively recently, UV design engineers have faced a dilemma. Open channel UV system design has typically been based on either a calculated dose approach, which assumes ideal flow and UV intensity distributions (not reflecting actual real system performance), or a conservative design approach, which ensures adequate performance, but often results in significant overdesign.

The first approach risks noncompliance, while the second approach risks wasting capital and operating funds. Currently, the only way around this dilemma has been to conduct pilot testing. Through pilot testing, the design team determines the site-specific dose response characteristics of the pathogens of concern together with appropriate UV system performance assessment, in order to develop the “best fit” design. Pilot testing an open channel UV system is a very expensive and time-consuming endeavor.

Recently, however, improved understanding of how different pathogens respond to UV light has resulted in a major positive shift in the necessary sizing of UV systems for wastewater, allowing for best-fit design without pilot testing. Qualified, extensive UV system validation testing that considers a large “validation envelope,” and is in line with existing guidelines, now offers utilities and design engineers a more cost-effective and scientific approach for open channel UV system design.

UVDGM 06

This positive shift in the necessary sizing of open channel UV systems was initiated following the publication of the UV Disinfection Guidance Manual (UVDGM) by the United States Environmental Protection Agency (EPA) in 2006, where different dose levels were determined together with log inactivation credits by surrogates.

Unlike alternative UV validation methods, such as the German DVGW W-294 and Austrian OENORM M 5873, which only test to a single UV dose setpoint of 40 mJ/cm2 Reduction Equivalent Dose (RED), the EPA UVDGM validation allows for the selection of multiple data points. The result is a highly flexible UV performance prediction formula that can be applied to a broad range of disinfection targets. This way, dose response behaviors—which vary by type of organism (always specific to the range tested)—are accounted for.

Cryptosporidium, an organism difficult to destroy with chlorine, is effectively inactivated by a relatively small UV dose, while viruses require a significantly larger UV dose to achieve the same log reduction. In order to properly describe the performance of a tested UV system on different organisms, a new term “DL” was established, which describes the dose required for one log reduction, also known as UV sensitivity. Incorporating such a term into a UV system’s validation formula, based on tests with surrogates exhibiting different UV sensitivities, allows one to determine how a UV system disinfects organisms of different UV sensitivity (“DL approach”).

DL Approach

The DL approach allows the UV system designer to determine a site-specific sensitivity via collimated beam tests for the project, in turn, allowing for “best fit” design instead of more expensive pilot testing—provided the design conditions are covered by the validation test conditions (validation envelope). The DL approach, based on the guidance provided in the UVDGM 06, may allow for increased flow capacity of given UV systems for wastewater—compared to previous design approaches. This offers the potential for significant cost savings, not only for upcoming wastewater projects, but many installed open channel systems in North America can also be reviewed according to the latest guidelines, thereby benefiting from favorable validation results.

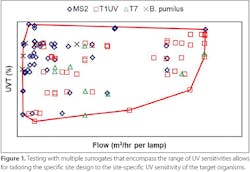

The DL approach allows for significant flexibility, depending on the validation goals and the potential applications for full-scale UV systems. A biological surrogate reacts the same way to UV light as the critical bacteria, but does not have the harmful impact of the critical bacteria. Testing with multiple surrogates that bracket, or encompass the range of UV sensitivities allows for tailoring the specific site design to the site-specific UV sensitivity of the target organisms (Figure 1).

This is ideal for wastewater designs where disinfection targets, UV sensitivities, and site-specific wastewater conditions vary. Because disinfection targets differ from site to site (such as in reuse and in discharge applications), typical indicator organisms can be bracketed using this multiple-organism approach to allow for best-fit design.

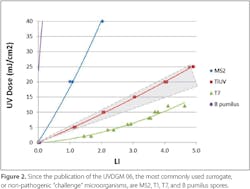

Since the publication of the UVDGM 06, the most commonly used surrogate, or non-pathogenic “challenge” microorganisms, are MS2, T1, T7, and B pumilus spores. This wide variety of surrogates is selected in order to bracket a broad range of sensitivities found in the field (Figure 2). T1 surrogate, for example, resembles coliform bacteria a lot better than MS-2.

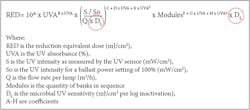

The validation formula developed, based on the testing protocol from UVDGM 06, allows for the integration of a specific UV sensitivity (DL) in which these different surrogates are tested spanning a broad range of UV sensitivities (Figure 3). This way, a design becomes possible that allows for the particular consideration of the site-specific dose response curve and, correspondingly, the DL of the pathogen targeted (which is easily established using collimated beam tests). The DL is then entered into this validation formula to allow precise dosage delivery based on that specific pathogen’s UV sensitivity.

Advancements In Technology Performance

The DL method addresses many of the earlier challenges regarding appropriate sizing of open channel UV systems for wastewater applications. Certain UV technology providers are now using today’s better understanding of pathogen-specific UV sensitivity along with technical advancements to make UV an even greater value proposition for public utilities and sewer districts.

Recent technological advancements made by Wedeco, a Xylem brand, include improving lamp and ballast technology to attain high power, energy-efficient, and long-lasting amalgam UV lamps; intelligent UV system monitoring and automated control based on real-time water quality, UV intensity, and other critical factors; more even-flow distribution, and inclined UV lamp orientation for space-efficient design, and ease of maintenance. These improvements have brightened the future for open channel UV disinfection, typically for wastewater treatment systems exceeding two million gallons per day (MGD) or 7,500 million liters per day (MLD) peak flow.

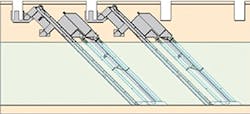

Wedeco’s Duron Inclined Orientation UV System (Figure 4) underwent validation testing in line with the corresponding guidelines from the National Water Research Institute (NWRI), International Ultraviolet Association (IUVA), and EPA. These tests, conducted under the oversight of Carollo Engineers, Inc., who also conducted the corresponding data analysis, enabled the equipment to be designed for a wide range of applications and for all different water qualities. Since its introduction in 2012, there are currently more than 30 Duron systems installed worldwide, including more than 15 in North America.

Demand-Based UV Intensity Control

To assure equal performance delivery during validation and full-scale UV system operations, all relevant parameters need to be monitored online. The Duron UV system’s sensor-controlled monitoring system monitors operating conditions in real time—including flow rate per channel, UV transmittance (respective UV absorbance), and UV intensity.

Control is based on these signals being continually applied to the validation formula with the site-specific DL value. The system’s UV lamp intensities are increased and decreased based on this formula. The control system is set to adjust the energy consumption to the minimum amount required to meet dosage requirements. It also adjusts the system operation in response to lamp aging, sleeve fouling, and changes in water quality.

UV intensity monitoring and control allows for precise adjustment of lamp power (and dimming capabilities), to match the dosage delivery requirements based on the current operating conditions, thereby maximizing savings of power and consumables, while constantly ensuring permit compliance.

UV Lamp And Lamp Orientation Improvements

Wastewater treatment systems seeking to use UV to disinfect flow rates greater than two MGD equal to 7,500 MLD often run into space constraints when evaluating the size of horizontal and vertical open channel configurations. Xylem’s Wedeco Duron is a 45-degree, vertically inclined, open-channel UV system. The system’s inclined orientation lowers building costs by reducing channel depth (greater than 37%) while also maintaining a small footprint.

In addition, the angled UV banks can overlap one another in series, eliminating the wasted space in between UV banks that is common with traditional UV systems (Figure 5). An integral lifting device on each UV module is designed to raise the UV banks out of the channel on a 45-degree angle (inclusive to a single plane per UV module) for easy accessibility to equipment below the water level.

The system uses energy-efficient, high-power lamps (Wedeco Ecoray) that have been shown to provide optimum UV intensity to penetrate the wastewater stream and generate the appropriate pathway for disinfection. The 600-W lamp significantly reduces the number of lamps and components required, compared to traditional UV systems, while maintaining a quality individual lamp efficiency at short length (1.43 M or 4 feet 8 inches).

The new lamp design, coupled with the inclined lamp orientation, has significantly reduced the number of lamps, components, and footprint required to treat medium to high disinfection flows using open channel UV installations, as well as providing for easier system maintenance. The inclined system can reduce lamp count and power consumption by 50% or more, making open channel UV disinfection feasible for larger flow facilities that would have traditionally ruled UV out based solely on the scale of the lamp count alone.

A Viable Option

Through a performance-driven, validated dose design, based on today’s better understanding of pathogen-specific UV sensitivity and the DL approach, an open channel UV system can be optimally matched to a facility’s site-specific water quality, flows, and other operating conditions and discharge requirements. This is accomplished while reducing the overall number of system components, energy requirement, and footprint of the equipment required for treating these flows.