This article discusses the management of various sources of construction water on large-scale (“mega”) construction and redevelopment projects. The sources can include high-flow dewatering applications, contaminated groundwater aquifers, stormwater contributions, and construction-related process wastewater. Managing these types of construction water sources can create significant challenges in meeting the compliance requirements of the National Pollutant Discharge Elimination System (NPDES) permit, local municipal separate storm sewer (MS4) requirements, and pretreatment discharge limits of the local publicly operated treatment works (POTW) facility. In a review of two case studies, this article explores design and permitting considerations and compares and contrasts the multifaceted approach to managing these sources in either segregated or commingled applications in the most cost-effective and risk-averse manner.

Snoqualmie Falls redevelopment project

Snoqualmie Falls Hydroelectric Redevelopment Project

The first case study evaluates the water management challenges encountered on a large-scale hydroelectric replacement project. The project was located along a highly pristine river that is not only a significant drinking water source, but also one of Washington state’s most visited tourist attractions. The project consisted of demolition of the existing hydroelectric plant, soil and groundwater remediation activities, as well as the site preparation and construction of the new facility. Construction on the project occurred between 2008 and 2012.

Because of the Federal Energy Regulatory Commission permitting requirements, proximity to sensitive receiving waters, and presence of historical contamination, this site required a detailed and complex water management plan to obtain coverage under the NPDES program. Furthermore, the project required US Army Corp of Engineers Wetland (Section 404 of the Clean Water Act) permitting and Hydraulic Project Approval by the Washington State Department of Fish and Wildlife.

In addition to the standard stormwater pollution prevention plan, the project required supporting documents: a sediment and erosion control plan, water-quality protection plan, and water treatment plan. All of these plans contained information regarding project phasing, source control measures, detailed water-quality monitoring, collection, treatment, monitoring, and contingency means and methods for handling multiple sources of construction water. Stormwater, non-contaminated groundwater, and cofferdam dewatering were all handled by one treatment method. Dewatering from Model Toxic Control Act (MTCA)–regulated soils remediation zones was treated using added tertiary treatment methods (virgin coconut-based granular activated carbon, GAC). Process-related construction water was recycled and reused as much as feasible and disposed of offsite as necessary, as required by the Washington State Department of Ecology (Ecology). The plans were required to be submitted and approved by federal, state, and local agencies, but Ecology was the lead water-quality regulatory agency for the project. The water-quality-specific permitting for this project resulted in an administrative order in conjunction with the general construction NPDES permit, which was the first of its kind at the time and which has been replicated several times on subsequent projects due to the success of this project.

Prior to this project, all sites requiring MTCA cleanup of contaminated soils also required individual NPDES permits to coordinate the Toxics and Water Quality Divisions of Ecology. This process was a long, drawn-out exercise that often required extensive remedial investigations, detailed and convoluted permitting requirements, and water management activities that often failed to meet water-quality objectives due to the remote nature of the projects, limited or no access to POTW sanitary sewer systems, and lack of effective, available, or practical treatment methods. From the treatment data generated on this and several similar projects, Ecology now has a database that recommends treatment methods for contaminants of concern and has incorporated the administrative order process in the general NPDES permit in an expedited fashion, allowing more projects to be developed in both economic and time-sensitive ways and allowing for expedited cleanup of contaminated soils throughout the state. It’s a win-win situation for business and the environment alike.

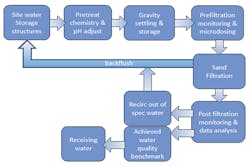

Water treatment systems were installed at three locations with a combined flow rate of 2,250 gallons per minute (gpm). Additional tertiary treatment was required for soil and groundwater contaminants of concern. The Plant 1 treatment system was designed with a 500-gpm capacity and the Plant 2 system with 250-gpm capacity; the Powerhouse system was the monster 1,500-gpm system. All systems used chitosan-enhanced sand filtration (CESF) as the base treatment technology for removing particulate-based contaminants of concern (Figure 1). CESF water treatment technology utilizes chitosan acetate, a natural biopolymer, and/or other Ecology-approved chemistry, in conjunction with pressurized sand filtration to remove suspended sediment from water in accordance with BMP C250 and BMP C251 from Ecology’s Stormwater Management Manual for Western Washington. Clear Water Services was instrumental in the development of CESF technology, which in 2007 received General Use Level Designation (GULD) from Ecology to be used on construction and industrial sites throughout Washington. By removing suspended sediment, associated metals, hydrocarbons, and other organic pollutants are also removed from stormwater. Chitosan also has demonstrated chelating properties with dissolved metals in stormwater solution, depending upon influent water quality. CESF systems can easily be augmented with enhanced pretreatment chemistry and/or adsorptive media filtration to further reduce the most common stormwater contaminants to non-detect at microgram per liter (µg/L) laboratory quantification levels. Due to the presence of soil contamination in the Plant 1 location, tertiary treatment using GAC was added to the CESF process. Table 1 further demonstrates the design criteria used in the treatment selection for the project.

It is important to note that although CESF was successful at removing the contaminants of concern related to the blasting agents (nitrate and ammonia), the project used significantly more chitosan polymer than would have been required if blasting agents were not used. At the time, Ecology would approve the use of chitosan acetate only for surface water discharge. However, recently Ecology has approved the use of blended polymers that utilize the chitosan biopolymer in conjunction with poly-aluminum chloride, which has shown much more cost-effective removal efficiencies when treating water impacted by blasting agents.

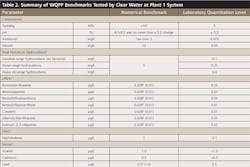

1 For Snoqualmie River: Turbidity shall not exceed 5 NTU over background when the background is 50 NTU or less. Turbidity shall not increase by 10% when the background turbidity is more than 50 NTU. With CESF in place, discharge turbidity shall not exceed 10 NTU in accordance with the GULD and AKART standards.

2 Ammonia and nitrate will be tested only if water is potentially impacted by the use of explosives.

3 Ammonia standards are pH and temperature dependent, per WAC-173- 201A. Temperature and pH will be measured with a field meter as each sample is obtained for analysis.

4 Parameters listed were detected at Plant 1 area at concentrations exceeding MTCA Method A soil cleanup levels for unrestricted land use. Dewatering water will be monitored and treated (if necessary) for these constituents during MTCA remediation activities in all areas delineated on the Plant 1 Erosion and Sediment Control Plan (Attachment 3, WQPP, May 12, 2009).

5 Value is less than the Reporting Limit. The lowest Reporting Limit is shown in parentheses.

6 Hardness data will be provided by Onsite Testing. Limits are for dissolved metals.

The Snoqualmie River not only provides sensitive habitat to endangered salmon and related species but also is a drinking water source for downstream municipalities. The water-quality benchmarks (Table 2) were extremely low and even reached the lowest level of laboratory quantification for polycyclic aromatic hydrocarbons (PAHs). The arsenic benchmark was also extremely low, especially given the presence of naturally occurring arsenic in the surrounding geology.

In total, the project treated and discharged over 60 million gallons within water-quality benchmarks. Another 12 million gallons were directly discharged from the cofferdam dewatering when the receiving water background was measured at over 50 nephelometric turbidity units (NTUs). Less than 80,000 gallons of process related wastewater was hauled offsite for treatment at the nearest POTW facility.

The site also required significant dewatering and conveyance elements, which were successfully managed throughout the project. The project was completed successfully without any water-quality violations and has been an example project for other sites with similar challenges.

Renton Manufacturing Facility

The second case study covers the management of contaminated groundwater and stormwater on a large-scale manufacturing facility’s utility expansion project near Lake Washington. Large volumes groundwater and stormwater flows required treatment prior to discharge to nearby surface waters, while significant volumes of contaminated groundwater had to be treated before discharge to the POTW. This section examines the permitting, design, installation, and ongoing operation and maintenance of water treatment systems on a highly dynamic project. It also covers the cost-benefit analysis of treating contaminated sources to surface water levels or to pretreatment levels required by the POTW. In addition, process water management considerations related to this project are discussed in relation to the overall federal and local regulatory requirements.

The overall project began in 2014 and is scheduled for completion in January 2017. The project involves excavation, demolition of existing utilities, and replacement with expanded utilities in a progressive linear approach on an active large-scale aerospace manufacturing facility. Because of the proximity to Lake Washington and shallow groundwater conditions, the excavation continues to involve aggressive dewatering using both well point and sump-based collection methods. The project also involves detailed monitoring and remediation of legacy groundwater and soil contamination containing organic compounds.

The project is permitted under the NPDES general construction permit for stormwater and non-contaminated groundwater (surface water) discharges. Treated contaminated groundwater discharges are permitted by a Major Discharge Authorization, which is regulated by the King County Industrial Waste Program. The facility has approval for daily discharge volumes to the POTW (sanitary discharges); however there was inadequate capacity to handle the additional stormwater and groundwater volumes of the utility project in addition to the process wastewater and pretreated contaminated groundwater contributions. Construction-related process water (saw cutting, concrete wash out) has been minimal on the project but has also been managed utilizing the POTW discharge option.

During the course of the project, nine surface water discharge systems have been installed ranging in flow capacity from 100 to 600 gpm. Two contaminated groundwater pretreatment systems were installed, both with 400-gpm capacity. One of the surface water treatment systems consists simply of particulate filtration using a 10-micron cartridge filter at a flow rate of 100 gpm. The remaining eight systems consist of flow-through CESF components to achieve the turbidity benchmark of 10 NTUs. The POTW pretreatment systems include CESF technology in addition to GAC with a contingency to add potassium permanganate to the effluent to precipitate out any organic compounds prior to discharge to the POTW. To date, the CESF and GAC systems have performed adequately to achieve discharge standards when organic compounds have been detected in system influent. All surface water discharge systems have met the permit benchmarks (below 10 NTUs and pH between 6.5 and 8.5 standard units).

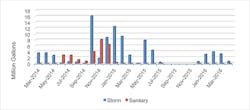

The two pretreatment POTW (sanitary discharge) systems have treated and discharged nearly 27 million gallons of water within permit parameters. The nine surface water systems have treated nearly 90 million gallons of water below permit benchmarks (Figure 2).

During the design phase of the project it was discussed that all of the construction related water sources, including contaminated groundwater and process water, could be treated to surface water conditions to reduce the costs and fees associated with discharging to the POTW. At that time, Ecology had not yet formalized the administrative order process into the general construction permit, and the estimated contaminated groundwater volumes were predicted to be much lower than what was actually encountered onsite. The presence of an existing sanitary discharge permit, estimated flow rates known at the time, and the unknown permitting vehicle led the project owner and engineers to maintain a course of segregating the sources and discharging to separate locations. This led to extensive conveyance, collection, and numerous treatment systems and associated relocation means and methods that added significant complexity and cost to the construction efforts. In retrospect, the permitting and risk aversion was clearly more straightforward; however, the overall cost to maintain compliance and segregated sources through traditional dewatering and conveyance methods was significantly increased.