As automation and computer control took a foothold in the operation and control of reservoirs and elevated water tanks, the industry moved the valve control from mechanical Automatic Control Valves (ACV) to Actuated Butterfly and Ball Valves. The primary reason being that actuators can be controlled by SCADA systems, which have been almost universally implemented in modern water systems. In doing so, many water system managers and operators have stopped purchasing the mechanical “Altitude Valve” which was the standard for many years.

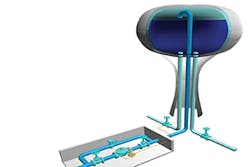

As a reminder, an Altitude Valve is a mechanical valve that uses a sensing line from the reservoir or tank, to a highly sensitive pilot, that allows the valve to open or close to maintain a user-set level of the water. Altitude Valves can be designed to open once the water level begins to drop, usually around 1 to 2 feet (0.3m to 0.6m), or can be equipped to allow for a user to adjust draw-down of the water level to allow for more tank or reservoir turn-over.

Altitude Valves are still used when a location at a tank or reservoir has no power, or where getting power to the location is extremely costly. They are also better suited to cold climates where a top layer of ice in a reservoir can interfere with electronic measurement. For smaller water suppliers that do not have the budget to implement a SCADA system, a mechanical altitude valve is still the best option.

HOW DO AUTOMATIC CONTROL VALVES WORK?

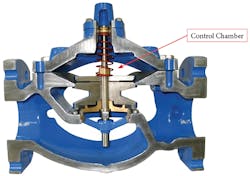

All diaphragm automatic control valves work on the same principle by using a rubber diaphragm to separate the upper control chamber from the actual water moving through the valve when it is operational. By controlling the water either going into the control chamber, or leaving the control chamber, the valve can be opened fully, closed drip tight, or modulated into any position in between.

WHAT ARE THE ADVANTAGES OF AN ACV?

The first key advantage is the fact that ACV valves are designed to modulate and control water at all varying flows, and butterfly valves were originally designed to be an open or closed valve. The advent of an actuator allowed a butterfly valve to be modulated, but it was not what the Butterfly Valve was truly designed for. Butterfly Valves and Ball Valves that are only opened a little bit are prone to cavitate and nothing much can be done to stop or control this.

- Many ACV manufacturers also have an option for an Anti-Cavitation Trim which can occur in Level Control Valves when a large inlet pressure is supplied by the system. As a general rule of thumb, anytime the inlet pressure is more than three times higher than the reservoir tank’s head pressure (which creates back pressure), the valve will cavitate. This cavitation can significantly damage the valve, as well as create a lot of noise and vibration. ACVs equipped with an engineered Anti-Cavitation Trim can stop all cavitation damage as well as quiet the valve down and reduce vibration.

- Almost all ACVs can be serviced inline without having to remove

it from the line it is installed on. This allows for a faster service with less downtime since keeping the system in operation as much as possible is key. - Costs can be more when using an actuated Butterfly or Ball Valve. Three-phase power to run an electric actuator can be expensive. The cost of a compressor with air lines for a pneumatic actuator can be the same cost. ACVs do not require these additional costs. In the event of a power failure, battery backups for the actuators are an add-on expense.

- ACVs have the ability to easily add additional features to the pilot system that make the valve more flexible. It is very inexpensive to add a pressure sustaining feature, or rate of flow feature to a mechanical ACV.

ELECTRONIC CONTROL OF ACVS

In the past, all ACVs have been controlled and operated using a mechanical pilot, which is a proven and reliable technology, but in today’s water systems, having control and feedback through the SCADA system is a desired feature. This is the main reason water system managers and consultants changed over to electrically or pneumatically controlled Butterfly Valves. But this is not the case anymore. Most ACV manufacturers have now adapted their ACVs to be operated and controlled electronically.

There are a few different ways, but the most common is by installing solenoid valves into the pilot system that controls the water flowing into and out of the control chamber. There is one solenoid valve that, when opened for a controlled amount of time, allows water into the control chamber, thus it begins to close the valve. The second solenoid valve, when open for a controlled amount of time, allows water to come out of the control chamber, which in turn opens the ACV a certain amount. By controlling how much water either moves into the control chamber or out of it, the valve can be opened, closed, or modulated. These solenoid control valves can be pulsed open and closed as much as the user wants to have the valve open closed

—or it can adjust the opening of the ACV to a very precise position. All that is required is a controller (Stand-alone PLC or SCADA controller) with a feedback sensor to the controller. The controller then gets feedback from a level sensor and makes adjustments to the ACV by pulsing the solenoids to open or close the valve.

ADDITIONAL OPTIONS FOR INCREASED CONFIDENCE

While having electronic control allows for excellent control and feedback of an ACV, during a power failure or outage this all changes. With battery backups, the ACVs and Actuated Butterfly Valves can be told to close fully, open fully, or maintain the last position, but this can have significant side effects. If the valve is told to close during a power failure, the tank or reservoir will not be filling during the entire outage, so the tank could drain very low, or completely if the power outage last too long.

If the valve is left open, the tank could overflow and a significant amount of water could be lost, which costs money as well as a wasted resource.

Unlike the Actuated Butterfly Valve, an ACV, which is electronically controlled as shown in Figure 3, can also have a standard mechanical level control pilot (altitude pilot) added to the valve as a backup in the case of a power failure. This way the valve would not need to go open or closed, but could now be controlled by the mechanical pilot and allow the tank to keep filling and then shut off when the desired level is reached. So it’s the best of both worlds and ensures the system is working at its optimum even during power supply issues at the tank or reservoir location.

SUMMARYAs the water supply industry continues to move to electronic control, using an ACV equipped with electronic solenoids is a better option for level control of tanks and reservoirs. By adding a mechanical backup pilot system to control during power failures or outages, it allows the system to work and maintain optimum water levels. In the event cavitation could occur, adding an Anti-Cavitation Trim makes the ACV an extremely versatile option for long-lasting level control with a guaranteed backup.