NON-REVENUE WATER (NRW) in its simplest form can be defined by the following formula:

NRW = Total Volume of Treated Water – Total Volume of Sold Water

Essentially it is the volume of water that the water utility spends money on treating and distributing that is not paid for by billed customers. The NRW level of a water utility is therefore often used as an indicator of the efficiency performance of the utility as a whole.

In 2006, the World Bank reported that more than 32 billion meters cubed of treated water was lost globally through distribution system leakage and an additional 16 billion meters cubed was delivered to customers but not billed. Based on these numbers, a conservative estimate of the annual cost of water lost is $14 billion. This problem of excessive water loss has continued to grow, as water utilities continue to allow aging infrastructure to age further, often due to a lack of funding in infrastructure rehabilitation, and as greater customer demands increase the stress on the already overloaded pipe networks.

WHY IS CONTROLLING NRW AN IMPORTANT ASPECT OF ANY WATER UTILITY?

The obvious answer to why controlling NRW levels is important is that it will improve the financial status of the water utility by increasing revenues from improved billing and reducing expenditure from lower treatment volumes and less leak and pipe burst repairs.

However, there are many other benefits including:

- Reduction in illegal connections or faulty meters creating greater fairness between customers.

- More efficient operation. Fewer disruptions mean improved customer service.

- Further investments in improving operational systems and assets as a result of improved cash flow.

- Decreased water waste.

In addition, many water utilities are publicly listed companies. Improvements in NRW can mean an increase in stock prices and, thus, increased company value.

WHAT ARE THE DIFFERENT COMPONENTS OF NRW?

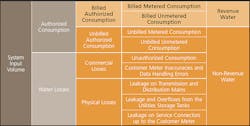

NRW is divided into many different components, but these can be grouped into two main components.

Physical losses—Where water is physically lost and fixing these issues would result in a reduction of water being treated:

- Distribution leakage

- Reservoir overflows

- Trunk main leakage

- Leakage on customer connections (up to the meter)

Commercial Losses—Where the loss is due to a measurement error:

- Production meter errors

- Customer meter errors

- Illegal or unmeasured use

- Billing errors

WHICH COMPONENT IS MORE IMPORTANT TO CONTROL?

All components have an effect on the level of NRW and the magnitude of each component can be different for each water utility. It is therefore important to ascertain the level of each component by undertaking an NRW audit.

This NRW audit will result in a simple table that will identify the level of NRW within each component of NRW. An example is the one shown below developed by the International Water Association (IWA).

Whoever undertakes the NRW audit needs to have a complete understanding of the different components of NRW so that they can visit all the required departments within the water utility and ask the correct questions. They also need to be impartial and willing to ask tough questions and report findings truthfully, often directly to the senior management in the utility. For this reason, water utilities usually hire an independent consultant to come in and review their existing NRW management activities and to produce a detailed report, which will be more honest and open regarding what is currently taking place.

Although the magnitude of each component of NRW will vary from water utility to water utility, it is important to look at all components when developing a company-wide NRW management program. These holistic NRW management programs will help to reduce the physical losses, while at the same time identifying commercial loss issues.

Often the commercial loss component is significantly less than the physical loss component due to aging pipes and assets, which are left in place well past their lifespan. Having said this, it is important to tackle the commercial loss components, no matter how small the component, as resolving these will have a direct impact on the income of the water utility and thus increase its financial capability to tackle the physical loss components.

HOW CONTROL VALVES CAN ASSIST IN THE MANAGEMENT OF NRW

Control valves have been used for many years to help control NRW levels and are still an essential part of any NRW management program.

Altitude and float valves are automatic mechanical control valves used to control the level in reservoirs or tanks. These control valves are used to ensure the reservoirs or tanks do not overflow and lose water down the drain.

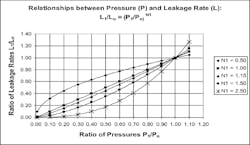

Pressure is proven to have an increased effect on leakage volumes and pipe burst frequency. The relationship between pressure increase and leakage volume is quite complicated and depends on pipe material, soil conditions, and the age of the pipe. But the ratio can be anywhere from 1:1 to 1:3, the latter case meaning a 10% increase in pressure would see a 30% increase in leakage volumes.

Pressure reducing valves (PRVs) are often used to control system pressures, allowing acceptable pressures to meet customer demands while maintaining a maximum pressure limit, ensuring leakage levels are controlled.

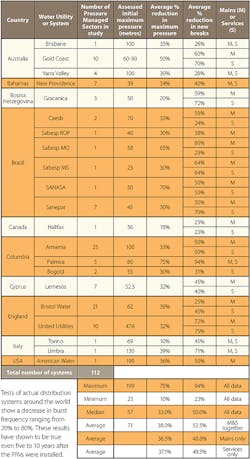

Some utilities are even using timer systems with multiple pilots to set multiple pressure settings throughout a 24-hour period. Singer Valve has developed a new mechanical version of this valve, which gives high pressure during high demand and low pressure during low demand.

Another bonus in installing PRVs is the effect of reducing burst frequency in old pipelines. Often the main reason for a water utility experiencing high leak and burst frequencies is the aging pipe network that has been asked to work beyond its expected lifespan. This means that these pipes are weaker than what they were designed for and thus any high spikes in pressure can cause bursts to occur on a regular basis.

WHAT ARE THE FIRST STEPS THAT A WATER UTILITY SHOULD UNDERTAKE TO START UNDERSTANDING AND MANAGING THEIR NRW LEVELS?

The first step as mentioned above is to undertake an NRW audit to ascertain the correct level of NRW and the magnitude of each component. This will enable the water utility to determine which components to tackle first and which would give the best results financially and on the NRW level itself.

It is also important to develop an understanding of the economic level of NRW within the water utility. This, in a simplistic way, is balancing the cost of managing NRW to the cost of the NRW losses. You don’t want to be spending more than you will save and you don’t want to lose more than you are spending. So it is a case of looking at both costs and figuring out where each water utility’s NRW economic balance point is. This economic level will depend on water tariffs, chemical costs, staff costs, equipment and vehicle costs, etc. It is quite a complex process to determine what a water utility’s economic NRW level is, but a necessary one as a wrongly set target can cause many problems later.

Once the utility understands the starting level of NRW, the magnitude of the various NRW components, and the achievable economic NRW level, they can then start to develop an NRW management plan. This NRW management plan should try to be as holistic as possible and cover many NRW components. The plan should identify all tasks to be undertaken and try to include a realistic target within a realistic timeframe at an acceptable cost.