INTRODUCING NEW TECHNOLOGIES in the water utility business is always a struggle because customers have to be shown that the product or service works as advertised. Not only that, but the technology has to be compared directly to a current standard practice to determine the relative efficacy and value proposition of the new method. Testing new treatment technologies is relatively easy in that multiple systems can be operated on the same influent water at the same time under the same conditions. This allows for a direct performance comparison between the products. Pilot testing on a treatment plant site, inside the fence, provides for a controlled experiment that can be repeated. Pilot testing new technologies in the distribution system, outside the fence, is more problematic.

The Prince William County Service Authority (PWCSA) has an ongoing commitment to continuously improve water service to its customers. One of the components of this commitment is an assessment of its water system’s transmission and distribution lines to eliminate leaks and identify pipes that may require repair, rehabilitation, or replacement. The PWCSA is also a leader in testing and deploying new and innovative technologies to enhance operations. In support of these two goals, PWCSA partnered with GHD to design and conduct a pilot study validating a new leak detection technology in comparison to its current traditional methods. Utilis has developed a leak detection technology that uses satellite spectral imaging and data acquisition, coupled with GIS-based algorithmic analysis, to identify potential potable water pipeline leaks. As a technology validation program, and to determine the best leak detection methodology for future leak detection efforts, GHD teamed with Hydromax USA to obtain satellite leak detection data. Hydromax provided the field leak teams for the satellite-directed inspections. The data collected was used to identify potential line leaks and to acoustically confirm and correlate the location of these leaks. Concurrently, the PWCSA tasked their current leak detection vendor with inspecting and gathering data from the same area for use in comparing the efficacy and efficiency of the two methods. The two programs focused on the same area of interest over the same period of time in order to be able to reasonably compare the results. The two programs proceeded independently of each other to avoid bias.

Traditional linear field inspection methods are compared to the Utilis satellite-directed method of leak detection. The current PWCSA leak detection efforts include selecting a water main investigation area and walking the entire pipeline route while using acoustic equipment to listen for potential leaks. The crew places the listening equipment over valves or other water system features that can be accessed without digging. When a signal is detected, a second correlating listening device is connected to the surface feature to determine the location of the leak. If a leak is correlated, the area is excavated and the pipe repaired or replaced.

Practiced leak detection professionals become familiar with the pipe network and begin their investigations in areas anecdotally believed most likely to exhibit leaks. The goal is to attempt to cover a certain percentage of area each year and increase success by closely evaluating leak patterns in the network. This kind of investigation can be challenging in noisy areas and it is not always easy to distinguish between a leak and water use if both are occurring at the same time. These factors can occasionally result in a leak identification where none exists or areas that require further investigation.

The Utilis satellite-directed leak identification methodology works by using technology to increase the potential of discovering a leak. A satellite image is taken and analyzed to create a three dimensional sub-surface image of a water network area of interest (AOI). Using specially developed algorithms similar to those used to detect water on Mars, the images are analyzed for the presence of water and trace chemicals in the ground. The technology can detect wet soil, which has a high electro-conductivity. Reflectivity, evidence of water, size of the water “plume,” and other considerations are used to detect the likelihood of a leak. This technology looks for a water plume in the ground; therefore, some environmental conditions such as creeks or other water bodies may prevent a nearby leak from being identified. Multiple satellite images are used to increase the accuracy and precision of the likely leak location map which is overlaid on the client’s pipe network to determine approximate pipeline leak locations using GIS coordinates. Points of Interest (POI) are generated to direct the field leak inspection crews to a target location where the investigation begins. The investigation protocol proceeds in a similar manner to the traditional method—using acoustic devices to listen for leaks at appurtenances and then correlating those leak locations. Areas investigated at a POI can be adjusted during the field investigation if the topography warrants. If there is a significant slope, the search pattern may be expanded to check areas uphill of the water plume shown in the satellite imagery. This is intended to increase the potential of locating a leak.

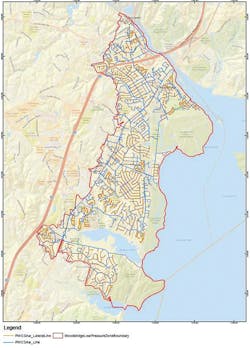

The PWCSA focused the pilot study, technology validation program, and AOI on the Woodbridge low pressure zone. This area includes approximately 200 miles of water main and service pipe as shown in Figure 1. This location was chosen due to its elevated age of pipe and because it has an estimated real water loss of 15%, which is above other sections of the PWCSA system.

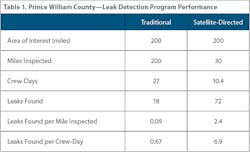

Traditional leak detection fieldwork occurred continuously from November 27, 2017, through February 1, 2018. The traditional leak detection crews performed a total of 27 days of fieldwork during this period. Satellite leak detection fieldwork occurred in three distinct deployments during a similar period—November 16–21, 2017; and January 3–11 and February 20–23, 2018. Satellite-directed crews performed a total of 10.4 days of fieldwork during these three deployments.

The results of the two leak field inspection programs are listed in Table 1. The Utilis satellite-driven inspections resulted in finding 72 leaks during the 10.4 crew-days of inspection. This calculates a metric of 6.9 leaks found per crew-day. The traditional method yielded 18 leaks in 27 crew-days for a performance metric of 0.67 leaks found per crew-day. The innovative satellite imaging approach was 10 times more effective than the traditional approach in finding leaks based on this temporal metric. The traditional leak detection team inspected all of the 200 miles of pipe mains in the Woodbridge low pressure zone area. This calculates a performance metric of 0.09 leaks found per mile physically inspected. The satellite-driven approach generated the 72 leaks from 30 miles of inspected pipeline for a performance of 2.4 leaks found per mile. The innovative method was 25 times more effective than the traditional method when analyzing performance based on this spatial metric.

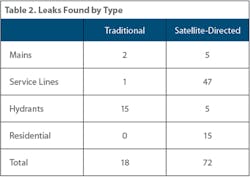

Table 2 shows the breakdown of leaks found by type. Of the 72 leaks found by the satellite-directed approach, 57 were non-revenue water (NRW) leaks; 15 were on the customer side of the meter. All of the leaks found by the traditional method were NRW leaks.

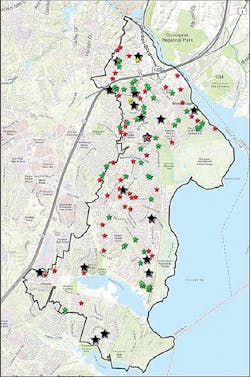

Figure 2 shows the spatial distribution of leaks found in the AOI during the study period. The black stars are the leaks found pursuant to the traditional methodology. The green stars are the leaks found using the Utilis satellite-directed methodology. The red stars are satellite-identified POI where no leaks were found when inspected. Because both crews were evaluating the same area during the same timeframe, there were some instances where the satellite-identified findings had already been repaired by the time the satellite field crews arrived on site. In Figure 2, where a red star and black star are in the same general location, the leak was identified and repaired prior to Hydromax’s fieldwork in this area.

The results from this validation study show that the Utilis satellite-directed leak detection methodology finds more leaks per time in the field inspecting or per mile inspected. This is due to the ability of the satellite image analyses to triage the pipe system and identify the most likely leak locations. This directs the field leak inspectors to an area that has a higher density of leaks, thus improving their performance and value metrics.

As can also be observed in Figure 2, there are clusters of leaks and Utilis-generated POI. This reinforces the Utilis value proposition because it validates the concept of non-randomness of leaks in a system. This data artifact has been seen in other study areas, where leaks are clustered around a number of satellite identified POI. This data can also be used in an asset management manner, whereby the clusters can be seen as potential areas to replace entire sections of pipe. The POI map can be used as a GIS data overlay to be used in conjunction with other information for utility managers to make capital repair and replace decisions.

There are a number of value benefits from the use of the satellite imagery to zero in on likely leak locations. More leaks are found in a shorter timeframe with less labor resources than with the traditional method. The value of the service comes in the reduction of non-revenue water, achieving water loss standards set by regulators, avoided cost of production, and reduction of catastrophic main bursts. It can do this remotely, without any capital expense or device installation or construction.

This study was well designed and executed and shows how cooperation between consultant engineering firms, utilities, and new, innovative product vendors can result in the generation of valid and compelling data on new technology which can be applied to the entire water sector.