On-Site Mixed Oxidants Help Combat DBP Formation

By Beth Hamm

Although the use of disinfectants in drinking water has drastically reduced disease, disinfectants can react with material in the raw water and form disinfection by-products (DBPs) that are also hazardous to health. Depending on the level of precursors in the raw water, mixed oxidants may be a viable alternative for DBP reduction while still providing the required chlorine residual.

Amendments to the SDWA in 1996 attempt to balance the risks between microbial pathogens and disinfection by-products. The Stage 1 Disinfectant and Disinfection Byproduct Rule (D/DBP) lowers the permissible limit for Total Trihalomethanes (TTHMs) to 80 mg/L. It also establishes a new limit for five Haloacetic Acids (HAA5) of 60 mg/L. These limits will affect all public water systems that add a disinfectant, regardless of their size. The rule went into effect in January 2002 for large surface water systems and goes into effect in January 2004 for groundwater and small surface water systems.

On-site generation of a mixed-oxidant solution, which consists primarily of hypochlorous acid, uses a process similar to on-site generation of sodium hypochlorite. A brine solution is fed through an electrolytic cell, power is applied, and the resulting oxidant solution is created. The style of electrolytic cell and operating parameters determine the formation of straight hypochlorite versus formation of mixed oxidants.

Mixed oxidants have been documented by numerous agencies to inactivate even chlorine-resistant microorganisms, much like ozone or chlorine dioxide. The solution will also leave a durable chlorine residual in the distribution system. Because of the presence of chlorine in the mixed-oxidant solution, the formation of TTHMs and HAA5 will still occur. However, anecdotal evidence from a number of installations shows DBP reductions ranging from 30 percent to 50 percent.

Mixed-Oxidant Chemistry

Manufacturer's claims of species other than chlorine in the mixed-oxidant solution have not been directly verified due to limitations of current analytical techniques and the complexity and interferences of multi-oxidant chemistry. Classical laboratory methods for detection of other oxidants do not function properly in the presence of a large chlorine matrix; thus, studies on mixed oxidants have detected only chlorine when using these methods.

Although the chemistry of the mixed-oxidant solution is problematic, the biology is compelling. Several performance characteristics of the mixed-oxidant solution demonstrate that it contains more than just chlorine. The most dramatic evidence is in the ability of the mixed-oxidant solution to inactivate chlorine-resistant organisms such as the Cryptosporidium parvum oocyst, or to achieve substantially higher inactivation levels of other organisms at a lower dose and shorter contact time than required with hypochlorite. The inactivation capability of a multitude of organisms using the mixed-oxidant solution has been demonstrated at a number of institutions.

Another key indicator for the presence of oxidants other than chlorine in the mixed-oxidant solution is reduction in TTHMs and HAA5, as demonstrated at a number of water utilities that have replaced conventional chlorination with mixed-oxidant technology. Although this phenomenon is not seen at every site, no installation has ever observed DBP levels with mixed oxidants that are above the levels produced by chlorine. In fact, in the great majority of mixed-oxidant installations, both TTHMs and HAA5 are reduced when compared to levels formed with chlorine.

Significant behavioral differences between mixed oxidants and chlorine have been observed both in laboratory testing and in field installations. There are several proposed explanations for the reduction in DBP formation in contrast to hypochlorite. These theories include preferential action of non-chlorine oxidants, elimination of biofilm, improved chlorine residual at a reduced dosage, and microflocculation to remove precursors.

Preferential Acting Non-Chlorine Oxidants

Chlor-oxygen species other than chlorine in the mixed-oxidant solution may be reacting with organic material in the water, reducing oxidant demand and eliminating some of the material that causes TTHM and HAA5 formation. These other species would be faster acting and preferentially react with components in the water before the presence of chlorine in the mixed-oxidant solution can cause an adverse effect. Since these other species would be short-lived and minute in comparison to the amount of chlorine present, they would not be sufficient to achieve total removal. Thus, the remaining organic material would react with the chlorine, producing TTHMs and HAA5, although at reduced levels. This theory is speculation and has not been proven.

Biofilm Elimination

Much anecdotal evidence exists on the ability of mixed oxidants to clean biofilm and algae from distribution system and clarifiers. Biogrowth that was able to survive with chlorine as a disinfectant is typically eliminated shortly after conversion to mixed oxidants. When a mixed-oxidant generator is first installed, flushing of the distribution system may be required to remove detached biosolids until the system has stabilized. The stabilization process usually takes one to two months, and then the lines remain free of biofilm or algae as long as mixed oxidants are used.

The ultimate effect is that reduced biogrowth lessens organic material that can react with chlorine, thus reducing DBP formation. Elimination of biofilms in distribution lines would mean that DBP levels in distribution would not be substantially higher than levels seen at the treatment plant. Data from a study done by H.R. Green Engineers demonstrates this effect.

Over the three months of the study period using mixed-oxidant disinfection, the levels of TTHMs in distribution dropped more rapidly than levels at the plant. When the site first converted to mixed oxidants, TTHMs in distribution were 36 percent higher than levels at the plant. After three months of continuous operation, TTHMS in distribution were only 14 percent higher than at the plant. Overall, the TTHM reduction in distribution was twice as great as at the plant.

Biofilm reduction was also observed at Diana Water Supply Corp. in Texas, where two line breaks occurred simultaneously. At that time, chlorine gas was used to disinfect one line and mixed oxidants were used to disinfect the other line. The line disinfected with chlorine contained biofilm only 200 feet from the disinfection station. The break in the mixed-oxidant line occurred about half a mile from the disinfection station, so the expectation was an even more contaminated line. On the contrary, the pipe exposed to mixed-oxidant treatment was spotless, as though it had never been used. Water from both sources was from the same aquifer and both lines were installed decades ago.

Improved Residual at Reduced Doses

The free available chlorine (FAC) residual from mixed oxidants is much more durable than the FAC residual from traditional chlorination. The mixed-oxidant FAC residual can endure for very long distances and stays in the lines for a much longer period of time. This is likely related to the removal of substances such as biofilm, which creates oxidant demand within the distribution system. Correspondingly, treatment plants typically notice a reduction in the required dose at the plant to maintain the same residual at the end of the line. After the distribution system has stabilized, most mixed-oxidant users report a 30 percent final reduction in dose at the clearwell. A secondary effect of the reduced dosage is a correlated reduction in DBP formation. Since chlorine requirements have decreased, there is less chlorine in the system that can react with organic matter.

Microflocculation

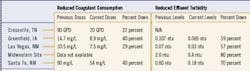

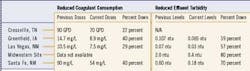

Microflocculation is defined as enhanced flocculation producing either a reduction in coagulant demand for the same final (filtered water) turbidity or a reduction in final turbidity at the same coagulant demand. An improved clarification process will demonstrate reduced turbidity, reduced DBP formation, and reduced chemical addition for such chemicals as alum and polymer.

Enhancing the coagulation process essentially removes several of the precursors for DBP formation. A variety of installations using mixed oxidants in pretreatment report a microflocculation effect and a reduction in TTHMs and HAA5 that is not seen with traditional chlorination. The fact that these sites were unable to chlorinate in pretreatment due to excessive TTHM formation further substantiates this theory. Although they are adding more oxidant overall, due to dual injection points, they see an overall decrease in DBP formation.

Conclusion

As the EPA enforces implementation of the new DBP limits, facilities will need to investigate the best technology for their site.

Mixed oxidants alone, without the use of any other chemicals or treatment techniques, have been shown to both reduce disinfectant demand and to reduce overall chemical usage. Although current analytical techniques can detect only chlorine in the mixed-oxidant solution, chlorine alone cannot account for the elimination of biofilm, reduced doses, and lower levels of DBPs that mixed-oxidant installations report. The operational improvements of treatment with mixed oxidants are well-documented and should be taken into consideration by any site designing or redesigning their disinfection process.

About the Author: Beth Hamm has 13 years of experience in the drinking water field, 8.5 years as water quality supervisor for Kentucky-American Water Company. Beth is employed with Commonwealth Technology, Inc. in Lexington, KY. Beth holds a Class IV-A Drinking Water License, serves as the chairperson for the Kentucky-Tennessee AWWA Water Quality Committee and heads up the CTI SDWA Task Force.