New Chemical Injection System Needs No External Power

A new chemical injection system can be installed directly into a water supply line and uses the flow of water as its sole power source.

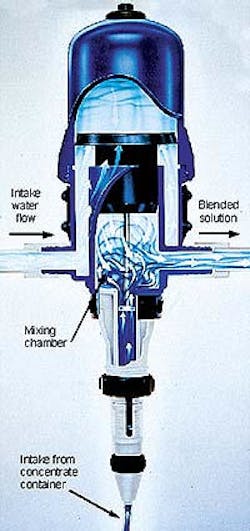

The Dosatron DI water-driven proportioner dispenser from Dosatron International of Clearwater, FL, requires no electricity or air pressure, so there are fewer things to go wrong. Water flow activates the injector, which takes up the required percentage of concentrate directly from the stock solution container. Inside the injector the positive displacement piston mixes the concentrate with water and forces the solution downstream. The amount of concentrate injected is directly proportional to the volume of water entering the injector, regardless of variations in flow or pressure which may occur in the main line.

Typical models designed for the municipal water treatment industry have a flow range of 0.05 to 11 gpm. The chemical injection rates vary per unit. Based on the chemical to be used, specific recommendations can easily be made. PVDF and Hastelloy options are available for use with aggressive chemicals. The most common units for polymer injection in wastewater sludge thickening and for drinking water metal flocculating are the DI1500 with ratios of 1:500 - 1:1500, DI16 with ratios of 1:64-1:500 and the DI150 with ratios of 1:20-1:100.

Typical municipal applications include polymer injection, injection of odor control chemicals, bacteria, and bacteria nutrients for lift stations and wastewater treatment plants. Water plants utilize them for disinfection solutions and corrosion inhibitors for drinking water systems and pipe maintenance. Most acids and bases can be dispensed for pH adjustment.

Typically, the injection units should be located close to the chemical source. The Dosatron proportioners are self priming up to 13 feet vertical. They can be plumbed in almost anywhere. The mixed product can be delivered almost any distance, provided there is sufficient water pressure in the line. In addition, the units can be used to inject multiple solutions in series.

Polymer Injection Case StudyThe 4 mgd Casa Grande Water Reclamation Facility (WRF) of Casa Grande, AZ, uses the Dosatron equipment for polymer dosing in its sludge thickening operation.The facility had been using a combination of a diaphragm pump, an electronic pulse metering device, and a static mixer. The old system had been a maintenance nightmare, requiring weekly disassembly and cleanout of multiple pieces as well as backup equipment to avoid costly downtime.

Jerry Anglin, Chief Wastewater Operator at Casa Grande, reported that installation of the Dosatron DI injector was quick and easy. All he had to do was remove the old system and drop the new injector into the plumbing line. No reengineering was required.

"I'm really impressed with it," Anglin said after the system had been in operation for six months. "I don't worry about my polymer injector anymore. My maintenance manager thinks it's great! Our maintenance has decreased from 8 hours per week, to less than 15 minutes!" WW/