Systems Improve Water Process Security, Optimize Treatment

Before Sept. 11, 2001 "water security" meant being sure you had good water to drink, and there was enough of it. Not any more! Suddenly, discussions are focused on the possibility of drinking water systems being purposely contaminated by terrorists. This created an entirely new perspective on how to assure potable water safety.

Now there are two issues facing potable water producers, water security and water quality. This dual requirement for water security and quality presents all plants, especially small ones, with a real dilemma. The city of Parsons, TN, found an affordable solution to the problem.

The Parsons water treatment plant was built in 1947. Original capacity was less than 1.0 mgd. In 1976 four new filters were added to increase capacity to 1.7 mgd. Today, the plant services over 1500 connections in the city and other areas of Decatur County. The water treatment plant is not manned 24 hours per day. When the operator is on duty, most of his time is devoted to running tests, checking chemical feeders, etc. Plant personnel needed other ways to optimize the treatment process and increase the operator's efficiency.

One instrument that was evaluated based on information received from other water treatment plants in the area was a streaming current monitor (SCM) from Chemtrac Systems, Inc. The SCM helps the operator determine when the proper coagulant dosage has been reached. A "set point" is based on the plant performance (effluent turbidity, color, filter backwash frequency and volume, sludge produced, etc).

The instrument has allowed operators to minimize coagulant feed and still maintain water quality. One feature that the operators found helpful was the alarm created when coagulant feed was lost. This helped prevent major water quality excursions and regulatory violations.

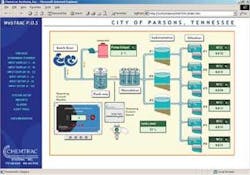

Another system evaluated at Parsons fulfills the dual need for security and quality. A JAVA based computer system that uses a standard web browser called WebTRACtrademark, also from Chemtrac, provides process data to password designated, on-site, or off-site locations via telephone line or the Internet. This means that the operator, plant superintendent, police department, or other party assigned a password, can know if critical plant processes are functionin properly. If not, alarms can be activated.

A unique feature of the WebTRAC system is that interfacing does not require a dedicated personal computer or proprietary software. All the process control, inputs, outputs, and data collection are done by the system's Web Access Controller (WAC). The information can be accessed by designated personnel via a web browser connected through the phone or network connection to the WAC. Video cameras can be included in the system to provide site monitoring and security.

The water treatment plant is currently using WebTRAC to monitor turbidity from each of its six filters; streaming current values and poly aluminum chloride feed.

Data is continuously transmitted to I/O nodes, then to the controller. The WAC has telephone and Internet connections. The plant is using the telephone line to transmit data to parties with assigned passwords. Operation is two-way in that some instrument settings can be changed offsite. Plans are underway to incorporated pH, chlorine residual, and various other operational parameters into WebTRAC. Water process security and treatment optimization have been achieved at the Parsons plant using Chemtrac's combination of instrumentation, process knowledge, and Internet capability.