Hydraulic Modeling Helps Streamline Operation

The City of San Diego has a progressive approach to water management and water use. In 2001, the city exceeded its water conservation goal by 18 percent. In addition, during the last four years more than 4.5 billion gallons of recycled water produced by the North City Water Reclamation Plant have been beneficially reused for irrigation, toilet flushing, cooling towers, dust suppression, and construction. The city has also developed its highly successful "Think Blue" citizens education program to provide more informed pollution prevention choices for its 1.3 million residents.

This progressive approach is also reflected in the city's Sewer System Planning and Management program. The Metropolitan Wastewater Department (MWWD), responsible for the planning, design, construction, operation and maintenance of the Metropolitan Sewer System, holds the distinction of being the first publicly owned wastewater treatment operation in the nation to receive the quality standard ISO 14001 Certification from the International Organization for Standardization in Geneva.

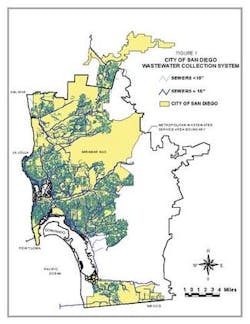

For the last four years, MWWD has applied dynamic hydraulic modeling to planning and operational issues across the entire Metro System. The city-wide system conveys wastewater via a network of trunk sewers and two major interceptors, terminating at a pump station that sends the wastewater flow to the Point Loma Wastewater Treatment Plant.

Built on the HydroWorks modeling suite from Wallingford Software, a model of the entire network has been used to predict flow and depths in major trunk sewers and interceptors. The model is used for sewer capacity planning and to develop strategies and analyze scenarios related to operation, maintenance and rehabilitation. The selection of the HydroWorks software was based on the need for an accurate and robust simulation engine, data viewing facilities, and real time control modeling capabilities.

The network model has been used over the years for a number of specific applications, including:

Force Main Shut-Down Analysis -

A pumping station discharges flow through two parallel force mains that need inspecting and maintaining, tasks that require operating the system using only one force main during the inspection of the other main. The model was used to ensure that shutdown would not cause overflows, by:

• establishing existing and forecasted peak flows entering the pumping station.

• determining maximum capacities of each force main.

• estimating the time when future flows would exceed these capacities.

• investigating alternative operating procedures.

Interceptor Rehabilitation -

The interceptor rehabilitation project involves replacing the existing PVC lining which covers the crown of the pipe. Work can only take place when the depth of flow is under 20 inches. Using the model, the MWWD was able to:

• determine for how long the desired depth of flow can be maintained.

• estimate the number of days during which no work will be possible to develop a realistic project budget and schedule.

Wet Weather Flows Diversion Study -

Pending completion of a new ocean outfall in 1998, the International Boundary and Water Commission requested that MWWD temporarily accept some effluent, with the effluent to be sent to the San Ysido Trunk Sewer tributary to the city's South Metro Interceptor. The model was used to:

• determine if sufficient capacity was available in the Tributary and the Interceptor

• develop an operating plan to control the temporary discharge and minimize environmental impacts.

Capital Investment Program Project Prioritization -

The system-wide model is a key tool in prioritizing capital projects, simulating the entire city's trunk system to evaluate the criticality of all 117 trunks (340 miles) based on the current and projected flows. Using additional information taken from trunk sewer televising (CCTV) plus the criticality evaluated by the model, the MWWD is able to prioritize the Capital Investment Program projects for the next 6-10 years.

MWWD's Senior Civil Engineer Guann Hwang explains in more detail the uses and benefits of a system wide dynamic hydraulic model:

"Trunk sewer planning is done on a trunk by trunk basis. With the model, we can detect the problematic sections and establish different solutions including upsizing the bottom neck or under-capacity sections, building relief trunks, or diverting flows from one trunk to other trunks to relieve any downstream capacity problem. Because the model can provide accurate flow, velocity, and depth evaluation, we can identify more refined and cost-effective alternatives for trunk sewer planning.

"The model is also used to provide hydraulic evaluation for various pump station operation procedures using the real time control feature of the dynamic model. For example, we estimated the maximum shutdown duration of a major pump station without causing a sewage spill, in the event of a total electrical blackout emergency," Hwang said.

"It's important to realize that this is not a one-off use of a 'throw-away' model for a single project. This is a system-wide model that is used continuously for all the various analyses I've described, being updated as the network is enhanced. In our application, we also link the modeling software with our ArcView GIS database.

"But it's not just about technology. At the end of the day, it's about cost-effectiveness. Good modeling software of the type we need, software with dynamic modeling capability and an accurate simulation engine, needs to be paid for, and we feel that cost is fully justified by the benefits. On a number of occasions we have decided not to invest in projects because of the analysis provided by the model. To take one example, after using the model to examine a sewer project which had been proposed to re-route a trunk around a to-be-built ballpark, we decided it was not required, thereby saving some $2.3 million," Hwang said.