Hawaiian Biosolids Project to Feature Egg-Shaped Digester

Chicago Bridge & Iron Co. has announced that its subsidiary CBI Services Inc. has been awarded a turnkey contract to design, supply, construct and start up an anaerobic Egg-Shaped Digestion (ESD) facility for Synagro Technologies, Inc. of Houston, TX.

The ESD facility will be part of Synagro's new biosolids treatment plant near Honolulu's Sand Island wastewater treatment plant. It will be the first application of ESD technology in Hawaii, and the second application of ESD technology at a biosolids pelletizing plant in the U.S.

Synagro is a U.S. wastewater biosolids management company that serves more than 1,000 municipal, industrial and agribusiness wastewater generators. The company's biosolids treatment plant in Honolulu will convert up to 10,000 dry tons per year of effluent from the wastewater treatment plant into a nutrient-rich, pelletized Class A organic material that will meet federal and state standards for beneficial re-use as a fertilizer.

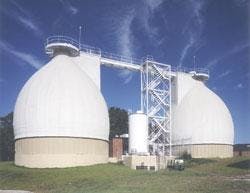

The ESD facility to be supplied by CB&I will comprise the front end of Synagro's plant, providing the wastewater digestion operation that is needed prior to de-watering and pelletizing. CB&I's scope of work will include a 2.4 million gallon Egg-Shaped Digester, a dome roof tank to store digested biosolids, and a dry seal gasholder to store digester gas, along with associated piping, foundations, mechanical systems, electrical/control systems and startup services. The facility is expected to be completed in the summer of 2004.

The Honolulu ESD facility will expand CB&I's record of service to the wastewater industry through the technology of its subsidiary CBI Walker, which has designed and installed more than 70 ESDs since introducing the technology in the U.S., including developing several patented and proprietary improvements.

The digestion process is beneficial for biosolids drying projects since it significantly reduces the volume of biosolids to be dried and disposed of, reduces purchased fuel costs by using self-produced digester gas to fuel drying operations, and produces higher quality, more marketable pellets. Egg-Shaped Digesters are particularly beneficial since they are gas-tight, compact, small-footprint units that maximize gas production while minimizing maintenance.