Utility Electronically Marks New Buried Sewer Force Mains

By My Huynh

Increasingly stringent wastewater treatment and disposal requirements set by the California Central Valley Regional Water Quality Control Board led the Sacramento Area Sewer District (SASD) to explore alternate solutions for the treatment and disposal needs of two communities in the district.

Extensive treatment plant upgrades would be required to allow SASD to continue operating the local treatment plants in Courtland and Walnut Grove. SASD studied conditions in the two towns and found that it would be more cost-effective to decommission the local treatment plants and instead construct a piped system to transport wastewater directly to a regional treatment plant.

As a result, SASD recently implemented two individual force main construction projects to convey wastewater from Courtland and Walnut Grove to the Sacramento Regional Wastewater Treatment Plant in Elk Grove. The large advanced wastewater treatment facility serves the greater Sacramento area and has sufficient capacity to handle an expanded service area.

Both of the 10-mile force main routes to Elk Grove are marked with buried radio frequency identification (RFID) markers to help satisfy mandated underground utility standards for damage prevention and to support infrastructure management.

Courtland Sewer Project, the first of the two force main projects, runs from the town of Courtland to Elk Grove. It began in the summer of 2007 and has been completed. It consists of an 8-inch force main and is equipped with two pumping stations. While a major segment of this new pipeline is in a straight line, several horizontal and vertical bends were required along the route.

Project specifications for the Walnut Grove Sewer Project are similar except that this force main consists of a 10-inch pipe. Construction began in June 2008 and will be completed by January 2009. The sewer pipeline route, which follows roads and streets between Walnut Grove and SASD’s connection point, includes several vertical and horizontal bends.

Both force mains pass under Interstate 5, the Union Pacific Rail Road, irrigation ditches and sloughs, and other buried utilities.

Route Marking

The California Underground Service Alert program in conjunction with California Government Codes require that utilities be able to locate all buried facilities with an accuracy of two feet or less. The conventional approach for marking wastewater lines has been to place tracer wire adjacent to a pipeline route for locating with above-ground equipment. However, the SASD finds that tracer wire can break, and soils in some areas promote corrosion, making it difficult to dependably locate underground pipelines over the long haul.

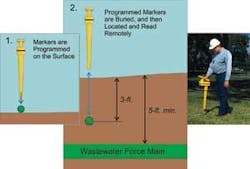

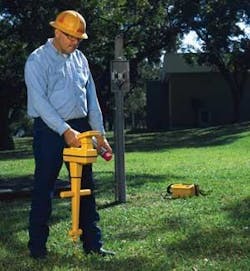

An SASD staff member learned of a new approach to buried utility marking at a trade conference. This method involves use of 4-inch-diameter spherical plastic markers that are buried with underground utilities at selected points along a route. These active RFID markers require no source of power, but unlike earlier passive markers, they can be programmed with pertinent information about the pipeline utility. After research and product testing by SASD, buried marker technology was chosen to mark the two new force mains as they are constructed.

Darlene North, a marketing manager with 3M Track and Trace Solutions in Austin, TX, explains that active RFID markers provide detailed information about individual marked points as well as pinpointing the pipeline path. Buried markers make it possible for a tool as small as a shovel to accurately reach a specific component or point along a utility route and thus eliminate the need for exploratory digging.

“Each marker has a factory-assigned serial number and bar code, which are recorded on as-built buried facility drawings for future reference,” North said. “Programmed location-specific data is recorded in markers as they are placed, with a hand-held device that is later used to locate and interrogate the same markers.”

Location-specific data for each marker is assembled in advance on a laptop computer, and then downloaded to the locator device and then to individual markers as they are placed. System software allows the cumulative data to be stored by job number for searching and sorting and lookup in the field, and the data is also used for automated mapping, facilities management and as-built records.

Programmable ID markers are available in standardized radio frequencies and housing colors as established by the American Public Works Association for each class of underground utility, including wastewater, water, telecommunications, gas, electric power and CATV.

Marker Programming

Circuitry in each marker allows for storing 256 bits of data, and coding and abbreviations are typically used to accommodate all information required for the application. SASD worked with 3M, the marker manufacturer, and SASD’s distributor to include compressed terms for marker programming that met the specific needs of the wastewater pipeline application.

3M met this request promptly, providing revised software for downloading to locaters purchased by SASD and the construction contractor. New drop-down options in the locators’ operating menus allow the construction contractor and utility crews to input custom SASD data.

3M and local distributor Northtown Company of Huntington Beach, CA, provided engineering support for the marker programming development, as well as training on marker use in the field for SASD and pipeline contractor, Mountain Cascade Inc. of Livermore, CA.

Pipeline Construction

According to Mountain Cascade project manager John Thieman, this is the first time his firm has used programmable markers in the placement of a buried pipeline.

“Our crews have found the system easy to use,” he said. “They program a marker with SASD data for each required location, and markers are buried directly above the pipe as the trench is backfilled, placing them at a nominal depth of three feet. The internal marker antenna that receives interrogating signals is self-leveling, so there is no need to orient the devices as they are dropped in the trench.”

Project specifications call for placing a marker every 350 feet along straight segments of the pipelines, as well as at turn points, around the radius of curves, and at points where force mains cross other utilities. Approximately 170 of the 1400 Series active markers were used for each of the two force main projects.

Thieman said GPS coordinates are recorded for each marker position to further define the route and clarify as-built records.

“This marking method has clear advantages compared to conventional tracer wire because markers tell you exactly what is there, how deep to dig, and details of any adjacent features that might be of importance to an excavator,” he said.

Electronic marking of new force mains will improve the integrity of SASD services, help protect underground utilities during excavation, and save time when it becomes necessary to locate and excavate these pipelines in the future. SASD has included electronic marking into their current construction standards. Contractors are required to program and install electronic markers whenever a new force main is built. WW

About the Authors:

My Huynh is a project engineer with the Sacramento Area Sewer District. Since 2003, she has worked in the wastewater and drainage industry, managing several large and small pipeline and pump station projects. She currently manages the development, design, and construction of the Courtland and Walnut Grove Sewer Projects.

Circle No. 211 on Reader Service Card