Medium Pressure UV Replaces Low Pressure System at Canadian WWTP

The operators of a wastewater treatment plant in Richmond, BC, Canada, have opted to replace the existing low pressure UV disinfection system with high output medium pressure UV. The WWTP serves the Riverport Sports and Entertainment Complex and surrounding residential areas in southern Richmond, near Vancouver.

The facility decided to switch to medium pressure UV because cleaning the low pressure system was proving to be difficult. Each of the two disinfection chambers contained 24 low pressure lamps. Automatic wiping was not an option with that number of lamps, so cleaning had to be done either manually or with chemicals. Both of these methods are time consuming and require the entire system to be shut down.

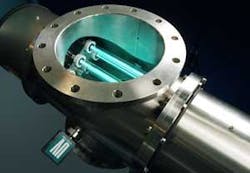

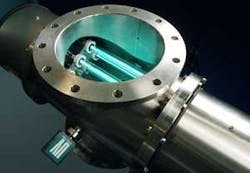

The operators decided to look at other options and medium pressure UV seemed an obvious alternative. While having a similar footprint, medium pressure systems use lamps with a much higher UV output than low pressure lamps. In fact, only two lamps per disinfection chamber are required for the same level of disinfection.

The two medium pressure units chosen by the Riverport facility were supplied by Aquionics. They are installed after a Sequencing Batch Reactor (SBR) and can treat a combined flow of up to 600 gpm of wastewater from the adjacent sports complex and residential areas. The disinfected wastewater is discharged into the Fraser River and meets all necessary quality standards for emission into watercourses.

In the new system, each of the medium pressure lamps is fitted with a mechanical wiper that automatically moves up and down the lamp's protective quartz sleeve, keeping it clean. Periodic chemical cleaning of the medium pressure lamps, if required, involves injecting the chemical into the treatment chamber where it cleans the lamps ‘in-line', without the necessity of removing the lamps or shutting down the system.

Each of the two UV chambers is fitted with a UV monitor which measures actual UV intensity and dose from the two lamps. This provides real-time disinfection information which can be downloaded for record keeping. Operating the UV system is simple and, when lamps need replacing, the job can be done by on-site staff.

The Riverport Sports and Entertainment Complex is a major development covering 36 acres in southern Richmond, BC. It contains movie theatres, swimming pools and spas, bowling alleys, ice rinks, shops and restaurants. The WWTP is a private facility serving the complex and some surrounding residential areas.