Lack of Vane Overlap Impacts Centrifugal Pump Performance By Allan R. Budris

The author was recently called upon to troubleshoot two seemingly different problems, which turned out to have a common cause. In both cases new replacement pumps encountered problems not experienced with the original pumps. Detailed investigations revealed that, although the general hydraulic performance of the replacement pumps was very close to the initial pumps, the new pump impellers had little or no vane overlap, compared to the older pumps.

What this seemingly subtle difference did was to increase the “Suction Energy” intensity (see October 2007 Pump Tips Column) of the pumps from the “Low Suction Energy” experienced by the original pumps, to “High” and “Very High” Suction Energy for the new replacement pumps. In one case it caused a submersible sewerage pump to experience severe cavitation, and damage, from low flow suction recirculation. In the other case it caused excessive cavitation at high flow rates, in a vertical turbine water pump, which liberated sufficient entrained air to damage the bowl bearings that were lubricated by the fluid pumped.

Suction Energy

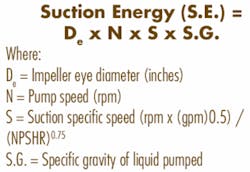

The concept of “Suction Energy”, as spelled out in the author’s October 2007 column, which he developed to identify when centrifugal pumps are likely to experience damage from full flow cavitation and/or reduced flow suction recirculation caused cavitation. The equation to calculate the Suction Energy of a specific pumps is:

null

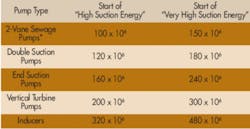

However, in order to determine the likelihood of damage the calculated Suction Energy level determined from the above formula must be compared with the pump type gating value from the following table (Table 1). This allows the calculation of the Suction Energy Ratio (Actual Suction Energy / Start of High Suction Energy Gating value). This ratio establishes pump Suction Energy Severity, where Low Suction Energy is defined as SER values below 1.0, High Suction Energy has SER values of 1.0 to less than 1.5, and Very High Suction Energy has SER’s of 1.5 and above.

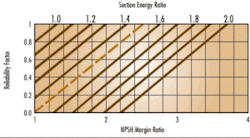

Low Suction Energy pumps normally do not experience cavitation damage or noise, High Suction Energy pumps experience cavitation noise, but little if any cavitation damage, and Very High Suction Energy pumps may experience major cavitation damage, along with cavitation noise, depending on the NPSH Margin.

* -Applies to all pumps with less than 15° of impeller vane overlap

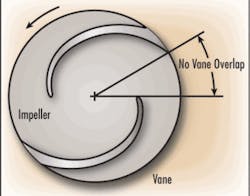

As noted from Table 1, the “2-Vane Sewage Pumps” pump type, which really applies to all pumps whose impellers have less than 15 degrees of vane overlap (see figure 1), has the lowest gating value (100 x 106, start of High Suction Energy). Insufficient vane overlap allows the higher pressures at the discharge of the impeller to recirculate (between the impeller vanes) to the suction, causing higher velocities and increased cavitation.

Field Problems

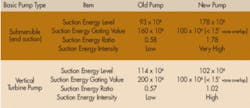

So how did the Suction Energy calculations come out for the initial and new (problem) pumps? Table 2 presents these results. The fact that the new pump impellers had less than 15 degrees of vane overlap resulted in significant increases in the “Suction Energy Intensity”, increasing from Low Suction Energy to Very High Suction Energy for the submersible pump, and from Low Suction Energy to High Suction Energy for the Vertical Turbine Pump.

In the case of the problem submersible pump, the “Very High Suction Energy” for the new pump was further aggravated by an elbow at the pump suction, and the fact that the system forced the pump to operate in the low flow suction recirculation region (which can require NPSH Margin Ratios over 10 to eliminate all cavitation under these conditions). This greatly increases the NPSH Margin Ratio values shown in figure 2 (which only apply to flow rates above the start of suction recirculation). These NPSH Margin Ratios should probably be increased by a factor of 2 to 2.5 in the suction recirculation region. So even with actual NPSH Margin Ratios above 3.3, the impeller experienced cavitation damage.

The vertical turbine pump had a different problem. The greater amount of cavitation caused by the lack of vane overlap, and the lower NPSH Margin Ratio (1.2) for this application caused the liberation of an excessive amount of dissolved air to become entrained air. This entrained air entered the bowl bearings, which caused them to fail prematurely.

So what should be the take-away from all of this? I think it is that, in addition to calculating the Suction Energy, Suction Energy Ratio and NPSH Margin Ratio for all new pump applications (and retrofits), special care should be taken to determine if the particular pump has at least 15 degrees of impeller vane overlap, and how it effects the Suction Energy Intensity. Remember that the amount of vane overlap decreases with increasing impeller trim, so the determination must be made for the specific impeller diameter for the application. WW

References: “Pump User’s Handbook – Life Extension”, by Heinz P. Bloch & Allan R. Budris, 2nd Edition, 2006, The Fairmont Press, Inc.

“Effects of Entrained Air, NPSH Margin, and Suction Piping on Cavitation in Centrifugal Pumps”, Allan R. Budris & Philip A. Mayleben, Proceedings of the 15th International Pump Users Symposium.

About the Author: Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits and litigation support on pumps and pumping systems. With offices in Washington, NJ, he can be contacted via e-mail at [email protected].

Circle No. 291 on Reader Service Card