Package Plant Helps Provide Quick Regulatory Compliance

by Anthony Galvan

The City of Bloomfield, NM, was notified that it had 18 months to bring its water treatment plant into compliance with regulatory standards. The water quality non-compliance stemmed from inadequate pretreatment to handle rapid changes in turbidity levels that is typical with the city’s surface water source.

With a population of 7,000, the City of Bloomfield is tucked away in the northwest corner of New Mexico, about two and a half hours from Albuquerque. Along with the compliance issue, there were other drivers that prompted the city to install a new treatment plant. The existing plant could only treat about 1.5 mgd and struggled to produce turbidities below 1 NTU. At times during the summer, peak water demand exceeded 2.5 mgd, which required renting filtering equipment to make up the difference.

The engineering firm CH2M-Hill evaluated various treatment technologies that could handle flashy waters, as weather runoff conditions could increase turbidities to around 400 nephelometric turbidity units (NTU). After a thorough evaluation of several technologies, the engineering firm chose a Trident HS package treatment system from Siemens Water Technologies.

The final selection was based on the ability to meet the regulatory standards; delivery of equipment, as set by New Mexico’s Environmental Department; ease of operation and maintenance; and ability to be easily expanded to meet future population growth.

New Treatment Plant

In a short period of 13 months, the 3 mgd surface water treatment plant was producing drinking water with a turbidity level of less than 0.14 NTU combined filter effluent – well below the regulatory standards of 1 NTU.

Bloomfield’s watershed is in the Vallecito/Pagosa area, which feeds the San Juan, Los Pinos, and Piedra rivers. All three rivers flow into Navajo Lake where the Bureau of Reclamation regulates controlled releases into the San Juan River. Approximately five miles downstream, water from the San Juan River is directed to the Citizens Ditch. From the Citizens Ditch, water is gravity fed to a head gate to the Aragon Reservoir, which is owned by Bloomfield. Water from this reservoir is released into an 18-inch water line that feeds the city’s treatment facility.

Raw water is pumped through a static mixer where a coagulant (ferric) is added, followed by inline injection of polymer. After the static mixer, the flow is split into two 1,050-gpm Trident HS units, followed by ultraviolet and sodium hypochlorite disinfection.

Treatment System

The Trident HS system is designed with four barriers: Barrier 1 consists of a tube clarifier section for bulk solids removal with external solids recirculation for improved clarity and chemical reduction; Barrier 2 is an up-flow adsorption clarifier that uses patented scarified buoyant media; Barrier 3 is a mixed media filter; and Barrier 4 is UV disinfection. The plant introduces sodium hypochlorite into the system for disinfection and to maintain a residual in the distribution system.

This is a two-tank system, with each tank treating 1,050 gpm, which allows plant redundancy for dialing down the flow as demand dictates or to shut down one treatment train for any needed maintenance.

Plant Performance

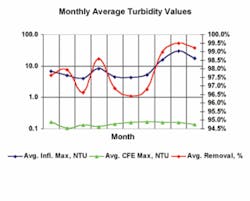

This plant was designed for turbidities up to 400 NTU to preempt increased seasonal runoff conditions. To date, the Trident system is achieving a combined effluent turbidity of 0.08 to 0.16 NTU and turbidity removal efficiencies of 96 to 99%.

The system was designed to meet the following criteria:

- 400 NTU turbidity max.

- 100 True Color units max.

- Iron & Manganese < 10 ppm

- Total log credit potential of 6.5

- An additional 1.0 log credit may be obtained for filters producing less than 0.1 NTU effluent

Once the water has been clarified and filtered, the combined filter effluent passes through a Wallace & Tiernan UV Barrier M medium pressure system for inactivation of pathogenic microorganisms. The treatment plant uses onsite sodium hypochlorite generation for maintaining chlorine residual. Before installation of the UV system, the plant was using a chlorine residual around 2 mg/L. Now with the UV system in place, reduction in chlorine residuals has been realized.

Reducing the chlorine usage may potentially reduce the Total Trihalomethane (TTHM) level. Although the plant has not experienced high TTHM formation, plant personnel wanted to stay ahead of the ever-changing regulatory limits. To date, there has not been a microbiological occurrence.

Conclusion

In just 13 months, the 3-MGD Trident HS surface water treatment plant was fully operational and producing water with a turbidity level well below the regulatory standard of 1 NTU. Regulatory compliance of 4 log inactivation of microorganisms has been met with the multi-barrier treatment system and disinfectant protocol of UV and chlorine residual in the distribution system. Bloomfield has consistently maintained a zero occurrence of Fecal Coliforms and E.coli.

The Trident HS multi-barrier system has proven to be an effective water treatment system for meeting regulatory standards and providing operational flexibility, and is also designed for future expansion capability while delivering lower overall lifecycle cost.

About the Author: Anthony Galvan is Technical Sales Manager, General Filter and Microfloc Products, at Siemens Water Technologies in Colorado Springs, CO. He can be reached at [email protected].