Bioscrubbing Solves Lift Station’s Odor Problem

Like many municipal wastewater-treatment authorities, JEA in Jacksonville, FL, is serious about controlling odors from its facilities. When the flow to one of its lift stations increased as a result of growth in the community, hydrogen sulfide emissions increased as well, to around 100-150 ppm at the wetwell vent without ventilation. That prompted JEA to start looking for a solution to the accompanying odor problem.

“We have as a goal zero odors outside our facility,” said Colin Groff, P.E., JEA’s Manager of Technical Services. “So when we get them, we immediately react.

“JEA is a very progressive company. We’re a big believer in technology. We’re trying to lower our costs to our customers using new technology. We have a lot of freedom to try new things, so I’m always looking for new technology to evaluate.

“One of the things we’re trying to do is find as much equipment as possible that is ‘green’ technology - in other words, biological rather than chemical technology,” he said.

With that in mind, JEA partnered with the Duall Division of Met-Pro Corp. (Owosso, MI) to pilot-test Duall’s new AroBIOS bioscrubber at the lift station.

“We had seen Duall at a show and talked to them about it. Because we were considering biological technology as an alternative approach we decided to do some short-term tests,” Groff said.

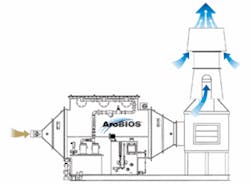

AroBIOS is a biological process that uses the concept of bio-scrubbing to treat gaseous odiferous compounds emitted from sewage treatment plants, said Greg Kimmer, Vice President and General Manager at Duall. It combines biological trickling filter technology with microorganisms that live within a unique biobed media called AroPAC. Unlike conventional scrubbers, it does not require the use and storage of chemicals.

The odiferous air is drawn into the system and passed through the biobed. As the air travels through the bed, during a contact time of typically 8-12 seconds, the microorganisms feed on the odor-causing substances as they are dissolved and dispersed in circulating water. The clean exhaust gas is then vented to the atmosphere through a mixed flow exhaust fan.

Test Results

Duall installed a 400 cfm AroBIOS bioscrubber designed to treat up to 120 ppmv of hydrogen sulfide at JEA’s lift station. The system has been in operation for more than a year, and test results were quite promising. According to Larry Cole, Duall Division Project Manager, “Efficiencies greater than 99% were achieved at a 10-second gas retention time (GRT) with inlet H2S concentrations ranging from 3.9 ppmv to 27.7 ppmv, and outlet concentrations as low as 0.03 ppmv were obtained.”

An unexpected power outage provided an opportunity to study how the system responds to upsets and to analyze the recovery period. The recirculation and nutrient pumps were shut down for three days causing the biofilm layer to dry out and significantly deplete the bacteria population. Fortunately, the mixed flow exhaust fan continued to dilute and disperse odors.

When power was restored, the pumps were restarted and the system put back into operation with a GRT of 15 seconds. Two hours later, a removal efficiency of greater than 95% was observed; the efficiency dropped throughout the day until stabilizing at 90% 12 hours later, and then gradually increased to around 96% on the third day, Cole said.

Four days into the recovery period, the loading rate was raised to as high as 44 ppmv by augmenting the inlet stream with H2S gas. Doubling the H2S loading rate helped to increase the bacteria count, although it did not affect the rate of increase in removal efficiency, he said.

Prior testing had indicated that when a moderate upset occurs, such as loss of nutrient feed, the bioscrubber requires about three days to return to 99% removal efficiency. Altering the operating conditions during the recovery period appears to stress the AroBIOS system, which lengthens the recovery time. After a serious upset, such as loss of recirculation water through the biobed, a recovery time longer than 3-5 days is required, Cole said.

“So far, our tests have been very good. We’re very, very pleased with the system,” Groff said. “We’ll start requesting bids from Duall when we need equipment at other facilities.

“We’re installing odor control equipment at seven or eight stations a year. Our goal is to be more proactive. Odor control personnel conduct baseline testing and monitor the incoming airflows, looking for increases. We try to install equipment before we get a complaint.”

Groff noted that JEA is trying to move away from chemicals and chemical scrubbers because of the high operating costs for the consumables. Vapor-phase treatment, such as the AroBIOS bioscrubber, involves a higher capital expense, but “with a biological scrubber, operating costs may be $1,000 a year, while the chemicals for the same level of liquid-phase treatment would cost around $100,000 a year,” he said.

The key to good odor control, he said, is to use liquid-phase chemical treatment where it is not possible to do vapor-phase treatment. For example, when the sulfur compounds are in the water, they can be treated with chemicals to prevent them from forming H2S in the air. But, he added, chemical treatment “is very, very expensive.

“JEA prefers vapor-phase treatment at specific locations such as pump stations because H2S is concentrated at one location. This is a much less expensive way to treat the odor from an operating standpoint. You have to spend money on the equipment, but that’s a one-time capital cost, spread over a 10-year period, which is the typical life cycle of the equipment.”