Moving Bed Filtration Helps Plants Meet Tougher Regulations

It is safe to say that every wastewater treatment facility in America has as its minimum goal the achievement of all applicable EPA and State criteria for BOD, nitrogen, phosphate and suspended solids (TSS). No one wants to be out of compliance. However, aging equipment, increased loading, and increasing volumes, combined with a reduced availability of funds and funding is creating a conundrum for the industry’s operators unlike any in modern history.

Fortunately, there are proven tertiary technologies that can dramatically improve the discharges of existing facilities. In the current funding climate, the use of these tertiary system additions is becoming the option-of-choice in the ongoing battle to achieve and maintain compliance with regulatory requirements.

One such tertiary tactic, which is proving to be popular to system operators, is the addition of moving bed filtration - both physical and biological - to their existing facilities. This type of filtration is relatively economical and is generally quite simple to operate and maintain. Moving bed filtration provides for biological phosphate removal and incorporates biological nitrification/denitrification.

A good example of current moving bed filtration technology is the upflow continuous backwash filter. This type of technology has proven its ability to remove metals, nitrates, phosphates and suspended solids in hundreds of installations worldwide.

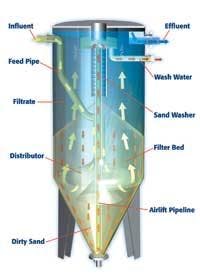

Upflow continuous backwash filter technology centers on a filter bed that is continuously moving downward as clean filtered water flows upward. The sand moving downward is guided by ambient water pressure into an air-uplift process enclosed in a central tube. The inlet of this tube is located near the base of the sand bed. As the sand is airlifted, intensive scouring movements separate the impurities from the individual sand particles. When the sand in the airlift system reaches the top of the unit, wash water is recycled back into the plant influent stream and the cleaned sand falls back onto the top of the moving sand bed (See Diagram).

The filtration process is comparable to fixed bed filtration, however, continuous cleaning of the filter bed allows for uninterrupted operation. The continuous nature of the process eliminates process interruptions and results in a high volume and constant filtrate quality. Using this approach, high levels of suspended solids are easily processed.

The continuous wash water flow is independent of the suspended solids load and the hydraulic load. Plus, the hydraulic head loss is limited and relatively constant. This makes implementation in existing treatment plants simple and gravitational feed possible. This process is suitable for physical-chemical as well as biological treatment or a combination of both.

In biological applications, the biomass grows on and between the grains of the sand media. The growth of the biomass is balanced against the continuous discharge of biomass into the washer at the top of the filter. Because there is a constant balance between the solids/biomass in the feed water and the solids/biomass discharge in the continuous wash water flow, filter bed resistance is more or less constant during normal operation. This means that relatively high hydraulic/solids loading can be dealt with, as compared to the loading that static bed sand filters can adsorb.

Also, in sharp contrast to batch filtration, no pre-treatment (such as flotation, and settling, etc.) is necessary, even in situations with a high suspended solids load. Also, the system contains no moving parts, so wear is minimal. With the continuous backwash moving bed filter, the simplicity of the design results in low operational and maintenance costs.

Conclusion

Moving bed filtration has proven to be a reliable, compact and highly cost-effective tertiary option for removing metals, nitrates, phosphates and suspended solids, and it may be one answer for meeting discharge requirements in this time of tight budgets and high demand. WW

About the Author

Julian Pauwels is Vice President of Process Sales, USFilter Davco Products, Thomasville, GA. He received his BSME from the Institute of Higher Technical Studies of Antwerp, Belgium, and has been actively involved in the industry for more than 30 years. Contact Pauwels at: USFilter Davco Products, 1828 Metcalf Avenue, Thomasville, GA 31792, Phone: 229-227-8742, Fax: 229-228-1312, E-mail: [email protected].