New Orleans Faces Long Road to Recovery

Even after the city of New Orleans is pumped dry it could be months before the drinking water, wastewater and stormwater systems are fully operational, according to experts who have experience with the system.

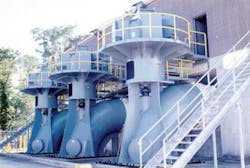

Several of the city’s stormwater pumping stations and the East Bank wastewater plant were flooded following the passage of Hurricane Katrina. The East Bank drinking water plant and the city’s power generation facilities also saw some flood waters, although water damage was relatively light. The West Bank drinking water and wastewater plants lost power and suffered some wind damage, but were not flooded.

In the distribution/collection systems, there was significant damage to the piping networks and lift station systems. The New Orleans Sewerage & Water Board’s (S&WB) facilities shop, where equipment and supplies are stored, was also flooded, according to sources.

The water board’s staff was not spared when floodwaters engulfed the city. Of the board’s 1200 employees, some 300 were on duty during the storm and all survived. Many of those not on duty joined the wave of evacuees who left the city and are now “scattered to the winds,” according to one source.

Like the rest of New Orleans, the East Side wastewater facility is essentially located in a bowl surrounded by levies. After the storm, that bowl was filled with about 14 feet of contaminated water, according to David Smith, Area Vice President for Veolia Water North America - South. Veolia has operated the wastewater treatment plants in New Orleans since 1992.

“The whole plant is under water,” Smith said in an interview on Sept. 12. “The one story buildings are completely submerged, including all clarifiers and the administration building. Basically we have a complete submergence of all mechanical and electrical systems.”

The four staff members on duty at the plant initially took shelter in a third-floor control room in the sludge incinerator building.

“During the storm event the building started to come apart and blew out the windows in the operations control room,” Smith said. “They relocated to fourth floor but then the wind started to blow off the roof. They went down to the second floor restroom which was concrete and hunkered down to wait out the storm.”

The operators were airlifted to safety on Aug 31.

The 99-year-old Carrollton Water Purification Plant saw minor flooding and also suffered wind damage that led to a fire during the storm. A 50 inch water main, one of six huge distribution pipes leaving the plant, ruptured during the storm.

The plant’s power system was running when hurricane-force winds blew an eight-foot-high window and frame out of the wall of the powerhouse. Horizontal rain poured onto a motor control unit, shorting it out and starting a fire. Plant staff controlled the fire using fire extinguishers.

When the levees broke in New Orleans, about three feet of water flowed onto the Carrollton grounds, forcing the decision to shut down the S&WB’s power generation system. By the Wednesday after the storm, gas-driven pumps had gotten enough water out of the powerhouse to begin restart procedures. By Sept. 11, the plant was back on line.

Drying Out, Cleaning Up

Once the water is gone, then comes the task of cleaning up the mess left behind.

“The first problem at facilities that end up under water is to clean up the mud, scum and trash,” said Howard Analla, an operations specialist with Black &Veatch. “All motors that have been under water will have to be inspected and more than likely dismounted and taken to a shop to dry out the electrical windings. The pumps themselves will probably be okay once they’re washed out.”

Analla is part of group at B&V that conducts annual inspections of the New Orleans water facilities through a contract related to the S&WB’s bonding agency.

Smith said Veolia will begin work at the East Bank plant by cleaning and dewatering the solids and sludge left by the flood, then clean and disinfect the buildings and equipment. They will then conduct a structural, mechanical and electrical evaluation and develop a detailed repair and replacement plan. That plan will be submitted to the S&WB, which will be responsible for financing and approving all repair work.

“The cleanup and assessment will be done almost simultaneously,” Smith said. “We will start at the front of the plant and work our way back, trying to clean, assess and order equipment for replacement as needed. As we get the equipment exposed, we will know more about the damages and that will improve the accuracy of our estimate.”

Electrical Systems

Whether at the wastewater plant or pumping stations, electrical systems will have to be dried out and inspected. Motor control panels, transformers, switch gears, speed controllers, and SCADA equipment at the plant will almost certainly have to be replaced, Smith said.

Motors that were not operating when flooded might be restorable if their windings are baked out and bearings regreased, Analla said. Otherwise, they will have to be replaced.

Once the electrical systems are repaired, they will have to be “recertified” by the local electric utility, Entergy, before the plant can come back on line, Smith said.

Plant Processes

The East Bank wastewater treatment plant is an enclosed high purity oxygen activated sludge plant. The oxygen generation equipment was out of service before the storm and the S&WB trucked in oxygen supplies.

“The plant itself is dead in the water. All biological process will have ceased,” Smith said. “We will have to re-cultivate the mixed liquor with feedstock from adjacent facilities to reseed the plant.”

The S&WB had recently spent about $8 million to clean the oxygen reactors. Since they are closed tanks, debris accumulation inside the tanks should be minimal.

“We hope the tanks themselves will be in relatively good shape,” Smith said.

The S&WB had negotiated a contract to rehabilitation the cryogenic facilities before the storm, and it’s possible that work will proceed.

Biosolids Handling

Biosolids from both the East and West bank facilities are burned at the East Bank’s incinerator. Smith said the incinerator suffered a variety of structural and mechanical damage, particularly to the multiple hearth furnace and fluidized bed. Arrangements are being made for the West Bank’s sludge to be trucked elsewhere for disposal. The East Bank plant has an alternative off-loading station for trucks directly from its belt filter presses, so the sludge could be trucked to a landfill for disposal once the plant begins operation and the filter presses are repaired.

“Long term, the viability of the incineration system needs to be looked at,” Smith said. The Water Board had already begun studying alternatives for biosolids management. “This would be an opportune time to look at a better method of disposal,” he said.

How long will it take to get the East Bank wastewater treatment plant back on line?

“It’s very hard to say until the assessment is done, but it’s safe to say it will be several months before any equipment comes on line,” Smith said. “We will have a better idea once the water is gone.”

Piping Network

Marty Dorward, MWH Vice President and Program Manager for New Orleans, is part of a team that has been assessing both the sewer system and drinking water networks in New Orleans. The Sewer System Evaluation and Rehabilitation Program (SSERP) is the group’s largest project. Driven by a consent degree with the EPA, the program is well underway and working toward completion by 2010.

Dorward said a significant portion of the wastewater collection system had been repaired before Katrina hit, but the unrepaired sections were in generally poor condition. Work on the drinking water distribution network was still in the early stages. The system was in poor condition, with much of it consisting of cast iron pipes 50 to 100 years old.

In New Orleans, many major water pipes run beside the roads, not under them. Hundreds of trees were blown down during the storm, damaging pipes both below and above ground. More damage may occur as the ground dries out.

Although the collection system will no doubt need repairs, the drinking water distribution system is of much greater concern, Dorward said.

“Once they establish pressure and fix the major leaks, they will have to disinfect and test the system,” Dorward said.

Analla said the typical process for a new pipeline is to fill it with a chlorine solution at about 50 mg per liter for 24 hours and then test the system. Disinfecting an entire network will be a major challenge.

“It may not be practical for them to disinfect all the sub systems,” he said.

One possibility is to pump a higher concentration of chlorine in water from the plant and then inject chlorine at various points in the system to keep the levels high, flush hydrants throughout the system and test for the presence of bacteria.

Another issue is the concern about contamination in piping systems of homes and businesses. One way to address the issue is for homeowners to allow their faucets to run for a certain amount of time to flush out contaminants.

“Letting the water run in all those faucets would put a big demand on the system. They already had a fairly significant water loss in that system because of its age,” Analla said. WW