DO Control System Reduces Power, Sludge Removal, Chemicals Costs

The two wastewater plants in The Township of Morris, NJ, have experienced significant savings in electricity costs, sludge removal and chemical usage after installation of a new system to control dissolved oxygen levels in the plants’ aerated digestion tanks. Regulated DO levels optimize the rate of tank aeration and reduce pumping requirements. They also provide a uniform and stable environment for the microorganisms that process the wastewater, which reduces sludge production and chemical usage.

Wastewater comes into the Butterworth plant from portions of The Township of Morris, Morris Plains, and Randolph. A smaller plant, called Woodland, treats wastewater from another part of the township. Routinely the Butterworth plant can treat 2.2 mgd, but can accommodate up to 10 mgd during storm surges.

Pretreatment facilities at Butterworth remove grit, rags and debris. Raw sewage pumps then send the wastewater to anaerobic and anoxic tanks to reduce the wastewater’s biological oxygen demand. These tanks also convert phosphorus to a readily removable form.

Next the wastewater moves to the aerobic stage, arranged in three trains of four tanks each. The plant uses only two trains at a time while the third train undergoes maintenance and refurbishment. Each train contains 947 fine-bubble ceramic air diffusers that aerate the wastewater to attain proper bacterial action. Early in this stage more air is necessary to satisfy the dissolved oxygen content required. The first tank, for example, has 316 air diffusers while the last tank in the train has only 180.

The wastewater then moves to clarifiers to decrease suspended solids. The clarified effluent flows through gravity sand filters, an ultraviolet disinfection stage, and a post-aeration unit before final discharge to the river. The plant re-circulates part of the flow to biologically break down nitrates and nitrites into nitrogen and to remove phosphorus. Thickened sludge is trucked away for disposal.

Activated Sludge Aeration

Sludge removal and electricity represent the Butterworth plant’s biggest expenditures. A large part of the electricity bill is for pumping air to the aeration tanks and for ultraviolet disinfection.

When the microorganisms in these tanks experience swings in the wastewater’s dissolved oxygen, the plant produces more sludge. Such swings can occur at night and on weekends when the plant influent rates decrease dramatically. Seasonal temperature changes also affect dissolved oxygen. Pumping more air into the tanks than necessary wastes a great deal of electrical power.

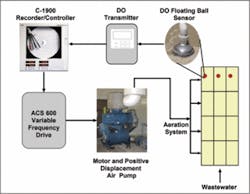

To decrease these costs, in 2001 the Butterworth plant installed a dissolved oxygen control system on the aeration tanks. The system, made by ABB, consists of dissolved oxygen sensors in the final tanks of the three aeration trains, an electronic recorder/controller, variable frequency drive, and a positive displacement blower driven by a 150 hp AC motor. The township installed a similar system at the smaller Woodland plant with a 125 hp motor. The estimated payback time was two years.

Using manual DO meters, plant personnel developed the proper air balance for the four tanks in a single train. When the four tanks are in equilibrium, a fixed relationship exists among the dissolved oxygen levels from tank to tank. This analysis determined that holding the DO level to 3 ppm in the last tank would optimize the DO levels in the preceding three, with the first tank assuming about a 1 ppm level.

Controlling DO Levels

The ABB Model 9408 system for sensing dissolved oxygen takes the form of a relatively large ball floating on the wastewater flowing through the final aeration tank. A flat-ended disposable DO capsule sits within the ball and flush with its bottom surface. The small capsule consumes reagents slowly, requiring replacement about every 9-12 months. No additional reagents, solutions or membranes are required. Users just unscrew the old disposable capsule and replace with a new capsule.

The floating ball configuration presents no way for materials to catch on and foul the system. Wastewater flowing under the ball continuously washes it clean. The ball rests at the bottom of a three-meter long boom attached by a swivel mechanism to the tank railing.

The DO signal from the capsule, along with a temperature compensating signal, connects to an ABB Model 4640 dissolved oxygen transmitter mounted to the railing. The transmitter compensates for temperature and elevation above sea level, and provides a local readout of the DO level. It transmits a proportional 4-20 mA signal representing 1 to 10 ppm DO to the nearby control room. To calibrate the sensor, personnel simply swivel the boom and rest the floating ball on the railing to get the air-saturated reading (8.5 ppm at sea level and standard conditions).

The associated ABB 1900 Commander controller in the control room, which includes a three-pen circular chart recorder, looks at any difference between its 3 ppm setpoint value and the DO readings from the two operating aerobic trains. It sends a compensating 4-20 mA signal to the ABB ACS 600 variable frequency drive. The recorder also tracks electrical power usage.

The ACS 600 controls the power to a high efficiency 150 hp ABB motor that drives the large positive displacement air pump. This pump replaces one centrifugal blower that lacked sufficient turndown to optimize control. Control valves on the inlets to the remaining centrifugal blower help regulate the second aeration train. Manually operated valves distribute the air to the individual tanks to maintain the optimum air balance. The result is tight control of the DO levels in the two operating aerobic tank trains.

Benefits

Anticipating a possible electric power rebate, Jersey Central Power and Light (JCP&L), monitored electrical usage at the Butterworth plant before and after installation of the DO control system. As a result, the plant received a one-time rebate from the utility of $80,000 based on the reduction in energy usage. The system significantly reduced peak and routine power requirements.

The state and federal governments closely monitor the plant’s sludge production and removal based on annual reports. In 2005 the state requested information on why sludge production had significantly decreased compared to previous years. The plant is consistently exceeding all the operational parameters mandated by the state. Consistent, uniform control of dissolved oxygen seems to be the key to sludge reduction. Microorganisms require a stable environment for optimum efficiency. Sludge reduction didn’t occur immediately, but over time as the plant fine tuned the DO control system.

Another benefit from consistent DO control is reduced chemical usage. During past winters the plant often suffered from massive foaming in the aeration tanks caused by the growth of undesirable microorganisms that thrived on excess air. Chlorine controlled the foam, but increased operating costs and represented a health and safety hazard. The stable dissolved oxygen levels provided by the control system have eliminated the need for chlorine to control foam, as well as additional chemicals to remove the chlorine.

Editor’s Note:

The authors would like to acknowledge the initiative and assistance of Jim Armstrong of Applied Analytics (Flemington, NJ) concerning the justification and design of the dissolved oxygen control system at the Butterworth and Woodland wastewater plants of Morris Township.WW

About the Authors:

Mark Howarth has been with the Township of Morris water pollution control facility for 24 years, and has been the superintendent for the last five years. Tim O’Dell has been with the department for 24 years and been the Assistant Superintendent for the last five years. Together they manage two treatment plants with a combined capacity of 5.3 mgd, nine pump stations and over 150 miles of sewer lines.