Automated Monitoring Improves Response, Treatment

The monitoring process within any utility or industry is a tedious task takes hours of labor, sampling, and analysis. As a result, utilities tend to decrease the frequency of monitoring in order to reduce the involved cost. A newly developed on-line analyzer can help reduce both the frequency and labor involved in sampling.

Shimadzu’s new TNPC-4110C analyzer measures total nitrogen (TN), total phosphorus (TP), and total organic carbon (TOC). The analyzer can be used for analysis/monitoring, as well as for process control. The sampling, treatment (physical and chemical), digestion, and analysis are performed automatically, rather than manually as with the currently used techniques. As a result, the analyzer can increase the frequency of analysis/monitoring from biweekly to hourly.

The TNPC-4110C analyzer was installed at a water reclamation plant in Columbia, MD, to monitor the influent into the biological nutrient reactor and, accordingly, adjust the biological treatment as required. Before installation of the instrument, monitoring of the influent was performed biweekly to reduce labor, time, and cost. The utility discharges about 18 mgd into the river.

Performing the analysis/monitoring manually not only meant decreasing the monitoring frequency, but also meant that the monitoring process would be subject to time and labor availability. Accordingly, some data about the nutrients level might not be generated due to such constraints.

Performing the analysis/monitoring process using the TNPC-4110C automatic analyzer meant that no labor is required in the process. As a result, no time is consumed in the process and no constraints are set in regard to performing the analysis and collecting the data.

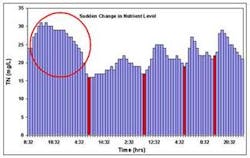

In addition, biweekly monitoring means less information about the nutrients level, which means either the water is over treated or under treated. Adapting an hourly analysis/monitoring using the TNPC-4110C analyzer resulted in a faster response to sudden changes in the nutrients’ level.

For example, Figure 1 displays a sudden change in the nutrients level, which would otherwise be obscured if the analysis/monitoring had been performed biweekly.

Increasing the frequency of monitoring also creates a database of information about the nutrients level within the selected streams in relation to seasonal and other factors. Developing a historical database not only provides information about the nutrients level, but also provides information that will facilitate better and more economical treatment and process control and, as a result, better overall management. WW