Dampeners Deliver Consistent Non-Pulsing Chemical Injection

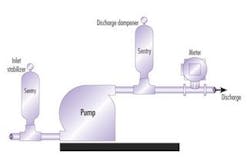

Reliability, consistency and dependability are major concerns when it comes to municipal water treatment systems. Pulsation dampeners and inlet stabilizers properly sized and installed in a chemical feed injection system will help insure safe, reliable and consistent flow of chlorinating and sanitizing chemicals.

Most chemical feed applications use a positive displacement type pump because they offer the advantage of being able to deliver the most precise and repeatable volume of liquid per given time. Although other types of positive displacement pumps are used for chemical feed, the most popular type is the controlled volume diaphragm type-metering pump. They are generally adjustable in stroke volume or frequency or both, so that almost any repeatable volume can be attained.

Positive displacement pumps and reciprocating types in particular, however, have a characteristic that can cause problems in liquid handling systems — pulsating start/stop flow. Reciprocating pumps have an intake stroke during which a chamber is filled with liquid and a discharge stroke that pushes the chambers liquid out of the pump. This start stop flow creates significant system pressure variations from virtually atmospheric to maximum desired pressure during every pump cycle. Multiple chamber pumps can be used to reduce pressure pulsations, but adding additional chambers can more than double the pump's cost as well as use additional energy for pump operation.

The start/stop flow characteristic of reciprocating pumps can also have significant negative effects at the pumps inlet. As the pump starts the intake stroke, liquid at the pump's inlet must be accelerated to fill the pumping chamber, during the pump's discharge stroke, liquid flow at the pump's inlet is immediately brought to a stop and then rapidly reaccelerated on the next inlet stroke. This cycle will repeat itself continuously during pump operation.

Depending upon system inlet characteristics, flow may not be adequate during the time interval available to accelerate liquid flow at a rate that will fully fill the pumps liquid chamber before the pump cycles. Incomplete pump chamber fill can cause erratic flow, increased pipe vibration and reduced system component life in the pumping system.

Pulsation dampeners and inlet stabilizers provide the most efficient, simple and cost effective means to minimize the damaging effects of pump generated pressure pulsations. Blacoh Fluid Control's extensive range of hydro-pneumatic pulsation dampeners/inlet stabilizers uses a bladder inside a pressure vessel to separate a compressed gas charge from the process liquid. The compressed gas acts as a shock absorber to dampen system pressure peaks during the pump's discharge stroke. During the pump's inlet stroke, the compressed gas charge forces accumulated process liquid back into the system piping. Flow and pressure variations are minimized so that liquid flow down stream of the dampener is virtually laminar and not turbulent.

An inlet stabilizer placed at the pump's inlet will accumulate process liquid. During the pump's inlet stroke the compressed gas charge in the stabilizer will force adequate enough liquid into the pump's inlet to insure proper pump chamber fill.

Dampening Benefits

Such systems can minimizes pipe vibration/hammer in piping. Most chemical feed systems consist of glued and or threaded plastic pipe and components. Pipe failure due to pump induced vibration can be eliminated using a properly sized pulsation dampener.

Peak flow velocity also is reduced. A properly sized pulsation dampener will absorb peak pressure spikes created by peak velocity, which means longer system component life and less activation of pressure relief valves. They can also help reduced energy consumption. Since a pulsation dampener changes start/stop flow into continuous flow, less energy is used because process fluid does not have to be reaccelerated on every discharge stroke.

Other benefits include reduced piping costs, the elimination of water hammer and increased accuracy and repeatability of flow metering.

Stabilization Benefits

Stablization systems can aid in complete pump chamber fill during the pumps inlet stroke. An inlet stabilizer placed at the pumps inlet will provide a source of accumulated process liquid to completely fill the pumps liquid chamber, insuring that pump system flow requirements are maintained.

They also can improve NPSH available requirements by assisting in overcoming acceleration head resistance — often allowing for smaller pipe — and will help minimize vibration-induced pipe and joint strain.

In effect, a properly sized and installed pulsation dampener at a reciprocating pumps discharge and an inlet stabilizer at the pumps inlet will change the flow characteristics of a reciprocating positive displacement pump into those of the continuous flow of a centrifuged pump.

Blacoh pulsation dampeners are constructed of PVC as well as a wide variety of other materials. They are available in sizes from 4 cubic inches to 10 gallons. Bladder materials include PVC, Buna, EPDM, and Viton. They are installed in many municipal and private water treatment facilities worldwide, protecting fluid handling systems from premature failure.