Meters Help Maintain Accuracy of Wastewater Billing

When you bill a customer monthly based on millions of gallons of wastewater treated, and the flow comes into your plant through one large force main, you need accurate flow measurement. And when that customer is feeding the wastewater into the main at a number of upstream points and calculating total monthly input based upon the sum of several flowmeter readings for those input lines, whose total do you use for billing?

This is the situation for the Iron Bridge Regional Water Reclamation Facility in Florida. It has a capacity to treat inputs at the rate of 40 mgd. It is operated and primarily owned by the City of Orlando. One major customer is South Seminole & North Orange County Wastewater Transmission Authority. This agency is referred to as the "North Authority."

Besides Orlando, the Iron Bridge facility receives wastewater flows from parts of Winter Park, Maitland, Casselberry, and unincorporated portions of Seminole and Orange counties. The North Authority serves about 150,000 people and on average, inputs about 9 to 11 mgd of wastewater to Iron Bridge.

Billing System

Once a month, the North Authority sends a Flow Report to the City of Orlando's Wastewater Billing Group. This report contains several input sub-totals as determined from readings of 25 flowmeters that the authority has for totalizing wastewater coming from area subdivisions. The city compares the sum of the authority's sub-totals with the totalized flow measured for the month by the "master" meter on the authority's input main. By mutual consent, the two totals should agree within five percent of each other.

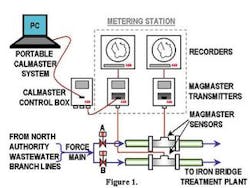

There are two master magnetic flowmeters installed in parallel on the two branches of the wastewater input main. Each flowmeter is connected by cable to its respective transmitter, mounted on the metering station panelboard. Above each transmitter is a circular chart recorder that plots wastewater flow rate on a seven-day chart and totalizes the flow continuously.

Only one magmeter is used at a time, while the other is for standby operation. Valves are installed on the two branch lines, upstream from the meter sensors. Operated manually at the station, one valve shuts off flow to the standby meter while the other opens the line to the active meter.

Until a radio telemetry system was installed last April, staff drove to the metering station twice a week, about 21/2 miles from the plant, to obtain totalized flow readings. Back at the plant, the totalized flow readings were e-mailed to the North Authority as interim "FYI" reports.

Installation of the radio telemetry system now provides automatic digital transmission of instantaneous flow and totalized flow readings every 30 seconds to the Iron Bridge facility. The telemetry is connected to a computer that logs the information and automatically sends e-mails to the North Authority. This not only cut travel time but also took over the task of e-mailing the information. What's more, the readings are truer because they are scheduled at exactly the same time (midnight) each day.

The telemetry system connects directly to the RS232 communications port of each magmeter transmitter. Freewave 900 Mhz spread spectrum radios have been selected; these units do not require an FCC license.

Along with the radios, two types of computer software are used: "Microsoft Visual Basic" and "Automate." Key Solutions, Inc., a consultant to the City of Orlando, wrote the Visual Basic Telemetry Interface to the ABB magmeters. The program, "Automate," provides automated dial-up networking and e-mailing of the flow readings to all appropriate parties.

Magmeters Chosen

The ABB MagMaster brand of magnetic flowmeters in a 24-inch size were selected for this project. The meters can measure wastewater flows up to 64.45 mgd. Daily flow rates from the North Authority vary over a wide range — typically from 900 to 15,000 gpm – but well within the range of the magmeter for accurate flow measurement.

A qualified ABB field service engineer visits the site on a yearly basis to check the calibrated accuracy of the master meters. The engineer uses portable equipment that enables him to verify and re-certify the factory-calibrated accuracy (one percent of flow rate). What's more, the engineer can do this at the metering station while the meters remain installed on the force main.

In addition to the feature of inline calibration checking, the magmeter offers a number of other advantages in this application. It has an unusually wide rangeability, providing measuring accuracy at lower flow rates as well as high flow rates. It has zero head loss with no obstructions to the flow stream. Also, its measurements are unaffected by changes in wastewater viscosity or density.

Inline Testing

The ABB field service engineer uses a portable electronic system, trade-named CalMaster™, to verify and re-certify accuracy of the two master meters. The system is designed to function specifically with the MagMaster meter, using original calibration data for that meter.

It has just two components and connecting cable. One component is a portable PC that contains the necessary software to carry out a pre-programmed verification procedure. The other is the CalMaster Control Box, which the engineer connects to the panel-mounted magmeter transmitter for the meter being tested. Note that each transmitter remains cable-connected to its sensor located in the vault.

The test checks out the entire magmeter system -- the transmitter, the sensor, and the interconnecting cable.

To confirm that test results meet approved standards, the service engineer reviews them on the PC's display. If he sees positive results, he prints out a certificate of validation for the tested meter.

The CalMaster can also serve as a diagnostic tool used for preventive maintenance on the master meters. It stores all previous validation data for each tested meter and, on its PC screen, can plot trend curves of data for selected components. If a curve shows gradual deterioration of the component, the affected meter can be repaired or replaced in-line while the stand-by meter takes over active measurement.

Acknowledgement: Information for this article was supplied by Roy A. Pelletier, Assistant Division Manager, and Andrew J Harbison, Instrumentation Chief, Environmental Services Wastewater Division, City of Orlando.