Agency Uses CMMS Data to Settle Insurance Claim

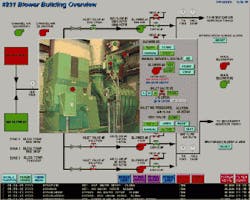

When a Computerized Maintenance Management System (CMMS) is established, the benefits include an enhanced understanding of system operations; better utilization of resources; and improved analysis tools for delegation of maintenance and rehabilitation activities. Improved generation of reports is another value-added benefit. Reports become easier to generate with their findings emphasized by graphs and photos.

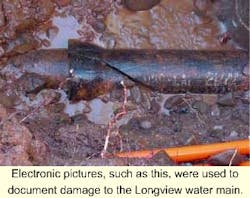

One agency, the Water and Sewer Department for the City of Longview, WA, found access to infrastructure data coupled with the ability to attach digital images to reports extremely beneficial. The department used its Infrastructure Management Software, from GBA Master Series Inc., to illustrate damage caused by a contractor on 52 linear feet of water line. A report outlining all associated expenses to fix the pipe complemented pictorial documentation of the damage.

Responding to the Damage Report

At approximately 2:10 p.m. on Monday, Sept. 25, 2000, the department received the damage report. To fix the pipe, nine Public Works personnel would need to work 26 hours of overtime and the department would spend $13,000 for materials. The repair procedures included hourly updates into the asset management, inventory and work maintenance databases of the CMMS. While the crew was in the field fixing the pipe, Jim Shier, superintendent for the Water and Sewer Department, was back in the office requesting estimates from suppliers to replace inventory.

Field crews finished their repair early the next afternoon. At that point, Shier was able to document the location of the damaged pipe, the actual damage caused by the contractor, and all department resources used to make the repairs. Despite what seemed to be an almost effortless compilation of all the information, he was unable to draft a statement. Waiting for suppliers to respond to his request for estimates on materials actually took longer than gathering the information for the statement. Shier finally received the cost estimates to complete the bill after 6 p.m. the same day.

By the close of business on Wednesday, the department produced a bill to send to the contractor. Shier knew the statement would be sent to an insurance company, so he gave meticulous attention to detail.

Statement Documentation

As expected, once the insurance company received the bill from the contractor, they had questions for Shier.

"I emailed a report to them that included the pipe identification number along with its location on GIS. I used a digital camera to attach images to the report so there would be no questions about the amount of damage. I had the crews update the databases throughout that day in order to produce an outline of their efforts. At the end of the day I sent the report," Shier said.

The ability to produce real time data provided significant cost savings, he said. He was able to reduce staff from several people to just one in order to produce the bill.

The insurance company quickly reimbursed all requested funds due to the documentation procedures. The contractor uses the case study and its related documentation as part of an internal training program. During a safety meeting, the risk manager presents copies of the work order generated by the CMMS, photos of the report, and a reproduction of the damage outline.

For the Water and Sewer Department, using the CMMS provided additional value. Legal counsel was not necessary to reach settlement on the claim. Access to "on-the-fly" information provided quick, accurate report generation, and a play-by-play of repair activities. In the end, ratepayers, the department, and even the contractor benefited from access to data as provided by the CMMS.

Longview, population of 32,000, is using its CMMS to track sanitary sewer inventory, water distribution inventory, customer requests, parts inventory, and maintenance. The city is also using the CMMS to update its existing GIS system. The integrated CMMS system was installed May 2000. Information in the existing GIS system was used to populate the sanitary sewer system and water inventory databases. The customer, work order and parts inventory databases of the CMMS were populated with imported information from other databases.