Disinfection Technology: Largest UV System in U.S. Protects Pittsburgh's Drinking Water

More than 150 community and industry leaders attended the official start-up of a new ultraviolet disinfection system at the West View Water Treatment Plant on Neville Island near Pittsburgh, PA. The system is the largest UV disinfection system for municipal drinking water treatment in the United States, and the first of its kind in Pennsylvania for surface water treatment.

The start-up was an historic milestone for West View Water Authority, which provides drinking water to approximately 200,000 residents.

William Wunderly, West View Water Authority's Chairman of the Board of Directors, said "the Sentinel system provides peace of mind for our 30 service communities who no longer have to worry about cryptosporidium and giardia, the potentially deadly microscopic organisms that threaten people with suppressed immune systems, such as children, the elderly and those who are ill."

Even though West View has never detected a breakthrough of cryptosporidium or giardia, a major wastewater treatment plant is located only a mile upstream from the drinking water plant's intake, said Joe Dinkel, Plant Manager and Assistant Executive Director of the West View Water Authority Neville Island Treatment Plant.

"There is always the chance for something to go awry, to get some form of breakthrough. This system is a perfect fit for our customers and mechanically for our system. It has a small footprint and serves as the very last step in the treatment train. Plus, the operating costs are negligible. We have very high demand service pumps, and we haven't seen any increase in electrical operating costs," he said.

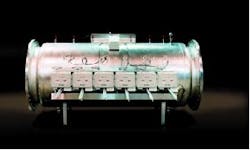

The Sentinel UV system, supplied by Calgon Carbon Corp., features a 48-inch reactor specifically designed to inactivate cryptosporidium, giardia and any future emerging pathogens. The design can accommodate the full plant capacity of 40 mgd.

As water flows into the plant it is dosed with chlorine, potassium permanganate, lime and ferric chloride as the coagulant. After flash mixing, the water flows through two Walker Process clarifiers, 20 mgd each. Filtration is provided by 14 granular activated carbon filters. In the clearwell, the water is disinfected with chlorine and/or chlorine dioxide as conditions dictate. Prior to distribution, the water passes through the UV disinfection system as a final barrier against parasites.

The Sentinel system features six high-intensity, medium pressure UV lamps. The lamps are kept clean with a Quickwipetrademark automated mechanical steel wire brush system that cleans the lamp sleeves and eliminates fouling to maintain consistent UV dosages. Automated operation and safety controls allow for minimal operator attendance.

UV dosage is paced by flow, with lamps added or turned off depending on flow, Dinkel said.

"With lower pumpages in the winter we might have only two lamps turned on, but in the summer we will have five lamps on, with one redundant lamp that can come on automatically if we have a lamp failure," he said.

Maintenance of the system will be performed under contract by Calgon, whose headquarters is in Neville Island, near the West View plant.

"This being a new technology, we wanted to be sure we are totally protected, and want to ensure that we have 100 percent operation at all times," Dinkel said.