Clay Pipe Facilitates Low-Cost "Pilot Tube" Soil Piercing Approach to Trenchless Sewer Technology

By Ed Sullivan

In many regions it is the smaller community with a smaller public works staff that leads the way when it comes to using new technologies. For example, pilot tube tunneling, an alternative to microtunneling, has been used by the city of Cape Girardeau, MO, for the installation of sanitary sewer lines as part of its overall sewer system modernization program.

Located approximately 100 miles south of St. Louis, Cape Girardeau has a population of about 40,000. When combined sewer overflows (CSOs) threatened the watershed in the early 1990s, the city and its project team commissioned a study to identify sewer system improvements. The team decided it was necessary to separate the sanitary and storm sewers, and thereby eliminate the CSO problem, in order to save the local watershed. The project improvements would be made through 2010.

Although the circumstances favored microtunneling - unstable soils, congested neighborhoods and business disruption - the city decided it could not afford the anticipated costs of this process and designed the projects as open-cut trenching.

As the apparent low bidder, Robinson Construction Co., a contractor from nearby Perryville, MO, requested a meeting with the city to discuss a trenchless approach for doing much of the work. The approach was the pilot tube technique of soil piercing. Although employing the subterranean installation of sewers in a manner quite similar to microtunneling, the pilot tube technique is less expensive than either microtunneling or open-cut trenching.

Although pilot tube technology can use PVC piping, Robinson recommended No-Dig vitrified clay microtunneling pipe. No-Dig, a division of MCP Industries Inc., is a manufacturer of rigid-bodied clay pipe for use in microtunneling, soil piercing, and pipe bursting. The first No-Dig installation was in Houston, TX, in April 1992. Since that time, over 220,000 linear feet of the pipe has been installed.

"There were several reasons for choosing the clay pipe," said David Monier, Robinson Construction Project Manager. "First, the material was readily available, and the clay pipe producer had a pipe designed for this particular process. Secondly, the product is more durable, which is required for this process because of the jacking forces involved with pushing, or jacking, the pipe through the earth. Third, the clay pipe was price competitive."

Mark Lester, Cape Girardeau City Engineer, readily agreed with the choices of pilot tube technology and the use of vitrified clay pipe.

"We were anxious to try out trenchless technology," Lester said. "We were certain that our project could be a shock to the community, which happens a lot of with open trench jobs. But pilot tube technology is eliminating most of those potential problems. It has saved us from tearing up a lot of street and inconveniencing a lot of people."

With regard to upgrading to the clay pipe, Lester says that while clay was not necessarily required, it eliminated the need for surrounding the pipe and surrounding soil with controlled low strength material (CLSM) plus buoyancy control.

Robinson Construction has been successful using microtunneling technology with clay pipe. Monier feels that the perception that it is an expensive solution whenever open-cut trenching is possible is often incorrect. He says the owner realized savings of $2,130,523 (15.1 percent) over open-cut trenching on five jobs. Installed costs for 6-12 inch pipe using the soil piercing technology is in the $100- to $175-per-foot range. Monier also notes that soil piercing equipment costs about $250,000 versus over $1 million for microtunneling equipment.

"Ultimately, microtunneling should be used everywhere possible, and open trench only when necessary or away from urban areas," Monier said. He pointed out that this technology is dominant in some parts of the world such as Japan and Germany, which are heavily urbanized.

The process of installing a sewer using pilot tube technology is similar to the microtunneling process, especially when clay pipe is used. Installation begins with the boring of two work shafts with a truck-mounted auger. The work shafts are bored to 6.5 feet in diameter and fitted with steel protection shafts, or 8 feet when a pre-cast manhole is to be installed.

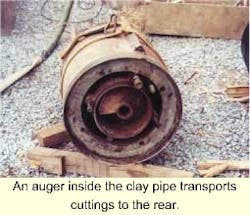

Once the shaft is in place, the construction team aligns a microtunneling machine using standard survey techniques. The machine pushes a 4 inch pilot tube by piercing the soil to precisely set the line and grade. Tolerances within the 0.1 foot vertical and horizontal are easily met. The pilot tube is rigid, ensuring that line and grade run true from start to finish. A cutter head with auger is fitted onto the pipe. The pipe is than pushed through along the path of the pilot tube, with the auger inside the clay pipe transporting cuttings to the rear.

The benefits of using the pilot tube soil piercing technology for tunneling for small diameter pipe installation are many. In addition to saving on the construction and social costs, this method reduces the amount of excavated material to be stacked/removed. Working problems in contaminated soils are minimized as soil is removed in slurry. The need to dewater the pipe trench, thereby significantly reducing the risk of collapse/settlement to surrounding structures and roads, is avoided. The need for man-entry is reduced, and operator-worker safety improved, because of remote control capability.

Once installed, intrusion of groundwater into the sewer line is prevented because the flexible joints of the pipes are sealed. The smooth internal finish of vitrified clay pipe provides optimum flow characteristics. And clay pipe provides a finished sewer line that is virtually maintenance free.

About the Author:

Ed Sullivan is a technology writer for Power PR, Torrance, CA