Johnson Screens- Zebra Mussels: New Screens Repel Zebra Mussels During Testing

Michael Ekholm

Zebra mussels invading the Great Lakes region have created serious problems for utilities relying on lakes and rivers for a water source. As mussels attach to raw water intake systems they can increase pumping costs, increase the velocity of flow through the screens to an unacceptable level, and eventually block intake screens altogether.

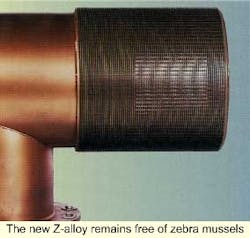

Johnson Screens, a USFilter Compa-ny, has developed passive intake screens constructed of a propriety alloy to which zebra mussels apparently won't attach. In a side-by-side test, the company's Z-alloy screens were installed beside screens made of 304 stainless steel. After several years of operation, the alloy screens were free of mussels, while the steel screens continued to need periodic cleaning to remove heavy coatings of mussels.

Johnson Screens offers a variety of screens for passive intake systems, including "Tee" and "Drum" type cylindrical configurations, flat screen panels, sieve screens and custom configurations.

The Vee-Wire used to fabricate the screens is naturally resistant to clogging due to its triangular geometry. Objects passing through the surface of retention (the flat part of the triangular wire) tend to pass completely through the screen. However, objects that willfully attach to the screen, such as the zebra mussel, have a clean surface on which to secure themselves. This makes the screens very attractive to the mussels when constructed of typical metals.

The condition of the screen surface is critical in a passive screen element. A passive screen operates by drawing water across its surface as evenly as possible. This feature allows flow through the screen to remain under a critical maximum intake velocity (normally 0.5 fps) that does not affect the environment around the screen (preventing impingement of fish and light debris).

The velocity of flow through the screen surface typically varies along the length of the screen. In the newest patented Johnson design, the control of this velocity is such that it is nearly even (within 90%) across the entire screen surface. With this performance efficiency, the size of the screens can be significantly reduced from previous designs.

However, this superior performance does require that the screens remain free of zebra mussel attachment to operate efficiently. As mussels attach to the screen surface, the screen area is reduced. This can reduce flow capacity, or cause the screen slot velocity to exceed the limits necessary to protect the environment around the intake point. While the screens are normally equipped with a Hydrobursttrademark system, an air backwashing device used to automatically clean the screen surface at periodic intervals, the attachment strength of zebra mussels exceeds the capacity of a normal system to dislodge them.

Johnson Screens conducted research to identify alloys that would not be attractive to zebra mussels. A wide array of special alloys and metal treatments were investigated before the current material, Z-Alloy, was formulated. The material is a high-copper content metal designed to be corrosion resistant.

Earlier research had shown that zebra mussels will not attach to pure copper coupons. However, there were concerns about the ability of copper screens to stand up in an underwater environment and remain effective when corroded.

Testing program

The material was first tested in coupon form in Lake St. Clair between 1990 and 1993. Coupons made from the Z-Alloy material showed little or no attachment over extended periods of time. Coupons of other material (acrylics, 304 stainless steel), did show significant densities of Zebra mussels (598,000/m2 for the 304 stainless screens). Coated materials tended to oxidize, and were ruled out as potential candidates for an effective long term solution.

The J.H. Campbell power plant, on the eastern side of Lake Michigan, was chosen for the first fully operational screen test. The operators of the plant had used passive intake screens for several years but had experienced problems with zebra mussels attaching to and blocking the screens. Access covers had to be installed on the existing screens to allow for frequent cleaning by divers. In many cases, even this was not adequate to keep up with the proliferation of mussels. The screens were periodically lifted out and cleaned on shore to clear the 1-3 inches of mussels that grew on the screen surface.

In 1993, a screen made from Z-Alloy was retrofitted onto one of the operational intake assemblies. In November 1999, operators at the plant examined the screens and found them to be clear of mussels. The Z-Alloy screens had not been cleaned since the initial installation and have not caused any interruption of service due to blockage for any reason.

As the screens were attached to a 304 stainless structure, the full surface of the assembly was not protected from mussel attachment. The side of the joining flange made from stainless steel was covered by mussels. The side made from Z-Alloy was free of attachment. The maintenance crew reported some normal light debris, but no permanent attachment of zebra mussels.

Conclusion

The screens will continue in service, and regular observations/videos made to record the progress of the test. The effectiveness of the alloy is not expected to be reduced over the service life of the screen, or over any reasonable period of time.

While Johnson Screens will continue to investigate new uses of this material, the results of this long-term field test indicate that the alloy is effective in resisting zebra mussels. The alloy is currently available for general use in a variety of intake systems and configurations.

About the author:

Michael Ekholm has been an application engineer for US Filter for the past 5 years, and was a product design engineer for the company prior to that. He has been involved in designing and improving raw water intake assemblies for a variety of installation locations and conditions as well as applying the company's screen technology to a wide range of industries.