UV Experience: UV Experience in Inactivating Cryptosporidium in Surface Water Plants

Gary Van Stone and Daniel R. Brooks

Over the past several years there has been a lot of concern over the parasites Cryptosporidium parvum and Giardia lamblia. It is known that chlorine does not have an effect on Cryptosporidium and that ozone requires higher doses to complete inactivation. Although chlorine treatment can inactivate Giardia, required CT's are higher which creates other problems including production of more disinfection by-products (DBPs).

Research into the use of UV light to inactivate Cryptosporidium and Giardia has been going on for sometime. For example, Clancy et al. found that UV doses between 4000 and 8000 mJ/cm2 resulted in > 4 log inactivation of C. parvum oocysts. These studies were conducted with low-pressure lamps that emit UV at the germicidal wavelength of 254 nm.

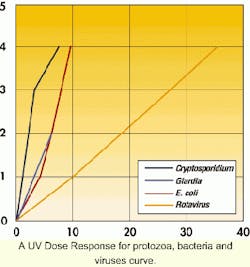

In 1998, research by Bukhari et al, sponsored by Calgon Carbon Corporation, reported 3.9 log inactivation of Cryptosporidium oocysts at medium-pressure UV doses as low as 19 mJ/cm2. Those results were developed using in vivo mouse infectivity assays. At this point it was widely known that UV could effectively inactivate bacteria and, with higher doses, inactivate viruses. To inactivate parasites such as Cryptosporidium and Giardia by way of UV was not even considered and thought to be impractical.

The Bukhari work changed all that and created a paradigm shift relative to the perception of UV irradiation as a disinfection/inactivation technology. It then appeared UV irradiation was more effective at inactivating the protozoan parasites at lower doses than the more common bacteria and viruses. Since then, there has been a flurry of research focused on using UV irradiation to inactivate Cryptosporidium, Giardia and emerging pathogens.

In 1999, Finch et al. investigated inactivation of Cryptosporidium (to repeat the Bukhari work on a different water source) and included in the study the inactivation of Giardia. The results supported the previous work indicating 4 log inactivation of Cryptosporidium at UV doses < 20 mJ/cm2. With Giardia, the results indicated a maximum of 3 log inactivation at doses of 20 mJ/cm2. In 1999, Clancy et al compared the use of medium-pressure (polychromatic) UV to low-pressure (monochromatic) UV for the inactivation of Cryptosporidium parvum. The results indicated that medium-pressure UV showed a 3.4 log inactivation at a UV dose of 3 mJ/cm2 and low-pressure UV achieved 3 log inactivation at 3 mJ/cm2. This indicates that for all practical purposes, UV irradiation, whether low-pressure or medium-pressure, performs similarly inactivating Cryptosporidium.

Reliability

Although only recently used in North America for large drinking water plants, ultraviolet disinfection has been widely used in Europe over the past 20 years. It is estimated that there are more than 2000 ultraviolet installations in Europe, primarily used for disinfection of groundwater. - The Sentinel 4x1 system

In North America, UV drinking water applications primarily have been limited to small groundwater plants. Although accepted under the Ground Water Rule (GWR) as an acceptable compliance technology, UV has not gained widespread use due to the acceptability of chlorine as a disinfectant. However, recent changes in the regulations addressing storage of chlorine and reductions in allowable Disinfection By-Product (DBP) levels have served to heighten the interest in UV within the water treatment industry.

Medium-pressure UV oxidation systems have been used for 15 years in the remediation of certain groundwater streams. Typically, hydrogen peroxide is used with UV to oxidize organic contaminants. Although a different application than drinking water disinfection, extensive experience was gained by the industry in the use of medium-pressure lamps, power supplies and lamp cleaning mechanisms in this application. UV oxidation applications require the power of the lamps to be high, testing the reliability of the power supplies. The waters being treated often contain high levels of dissolved solids creating an environment for scaling-especially with the high-powered, medium-pressure lamps. This tests the reliability of the cleaning mechanism.

Reactor Validation

One of the challenges to UV application is confirming that the reactor is delivering the design dose. Unlike other treatment devices, it is not possible to measure inlet and outlet levels of contaminants to determine treatment efficacy. This problem is compounded when a UV reactor is used for Cryptosporidium inactivation since the protozoan is not destroyed, but simply prevented from replication through alteration of its DNA. In an application like water treatment when human health is of interest, dose validation becomes a critical concern.

One method used to confirm the dose of a reactor is through biodosimetry testing. Here, a known microorganism (such as MS-2 bacteriophage or Bacillus subtilis) with a known dose-response is delivered to a reactor under design flow conditions. The efficacy of UV treatment is determined by measuring the amount of microorganisms that are killed by the UV system. The amount of microorganisms that are killed is then compared against the known dose response and an effective dose delivered can than be calculated. This can then be used to confirm that the reactor is delivering the specified dose.

In Europe, this validation is done through third party testing at a UV validation center in Germany. Each specific reactor undergoes biodisimetry to confirm the manufacturer's claims. The major limitation is the size of the UV reactor that can be tested, since extremely large reactors would require an impractical amount of test microorganism. This problem becomes more of an issue when surface water plants are considered since they typically have extremely large flows compared to ground water installations.

One solution to this problem may be through a combination of biodisimetry testing and modeling. Computational Fluid Dynamic (CFD) modeling would allow the fluence rate (or irradiance) distribution within the reactor to be accurately predicted and to be a good indicator of the delivered dose at other conditions. At lower flows and for a specific reactor design, correlation could be shown between CFD modeling and actual biodisimetry. Once the model is validated, larger reactors could be certified with CFD modeling without the need for prohibitive biodisimetry testing.

Sensors

When it comes to confirming dose delivery, sensors remain a critical issue. UV sensors indicate the presence of UVC light and can detect the deterioration of lamp performance over time. Proper sensor utilization requires correlation of the startup reading of the sensor with the validated reactor. Over time, each lamp's output will drop and the sensor reading can be correlated to provide an indication of this reduction. Ultimately, alarm conditions would alert the operator if the UV reactor were delivering less than the design dose necessary to achieve the specific treatment requirements.

Lamp Fouling

Unlike low-pressure lamps, medium-pressure lamps can produce extremely high temperatures on the surface of the quartz. In the presence of certain metals or contaminants in the water, this high temperature may cause fouling of the quartz. For this reason, it is important to employ some method of cleaning the quartz surface.

All automated quartz-cleaning mechanisms involve moving either a mechanical or chemical cleaner over the surface of the quartz at periodic intervals. Mechanical cleaners typically consist of either a wire brush type or a Teflon ring assembly that is driven either pneumatically or with a screw drive. Chemical cleaners use a food-grade chemical that is contained within two O-rings that travel the length of the quartz and are driven in a similar fashion. Wire brush-type cleaners provide the most aggressive scouring of the surface as compared to Teflon-type cleaners. Although chemical cleaning has proven successful, there is a natural aversion by the water plant operator to potentially introduce a chemical contaminant to finished water.

Surface Water Treatment

In a typical treatment scheme, UV disinfection system could be installed post-filtration and prior to or after the clearwell. Working with water having a consistently high transmittance helps ensure good performance.

In unfiltered applications where the water has relatively high transmittance, UV could be used at the treatment plant influent. The key to effective use of UV in these applications is having a design that is conservative relative to the water transmittance. The performance of the system will be identical after compensation for transmittance.

The only significant change to the traditional treatment process would be the potential reduction in the amount of chlorine used. If the current chlorine usage exceeds the chlorine demand of the water, it may be possible to reduce the chlorine level and achieve the same, or superior, disinfection through the use of UV. This would be predicated on the regulatory agency granting the proper credits to the UV disinfection system to allow this. It is unlikely that chlorine could be totally eliminated, due to the need for upfront slime control and residual levels in the distribution system.

Pilot Units

Determining the long-term performance and feasibility of UV systems for the treatment of surface waters has been the focus of several studies. Major ongoing studies are summarized below:

"Evaluation of UV disinfection systems for the inactivation of Cryptosporidium." In this American Water Works Association Research Foundation (AWWARF) study, conducted by Carollo Engineers (Boise, ID), a low-pressure unit, two low-pressure, high-output units, and a 4 X 1 kW Sentinel medium-pressure unit are being piloted at three Wisconsin utilities; North Shore Water Commission in Glendale, Neenah Water Utility in Neenah, and Cudahy Water Utility in Cudahy. The study involves long-term testing of UV disinfection unit performance. Major components include continuous operation and monitoring of the pilot units combined with periodic MS-2 challenge studies and by-products monitoring.

Initial results were reported at the 2000 AWWA National Conference. Results were extremely encouraging for the Sentinel medium-pressure unit, with major findings summarized below:

- The unit was operating well and providing a UV dose that met or exceeded the manufacturer's design specifications

- There was no negative impact of dropping water temperatures on the unit's efficiency (in winter, temperatures were near freezing point)

- The power consumption was very stable

- The Sentinel system had the lowest pressure drop of all systems

- Sensor readings demonstrated good stability of the sensors. There was some fluctuation that was attributed to changes in water quality. Overall, sensor-reading values were decreasing over time. The most likely explanation is believed to be the drop in lamp output (expected to be 15 to 20% over the operating life of the medium-pressure lamps, i.e. 3000 hours).

Long-term Performance

A main objective of the study, conducted by Montgomery Watson (Pasadena, CA) for the Los Angeles Department of Water and Power (LADWP), is to determine the long-term performance of the Sentinel medium-pressure UV system for unfiltered waters. A 4 X 1 kW pilot unit began operating in April 2000 and operated continuously until December 2000. MS-2 challenge studies were completed on a monthly basis. Through parallel, bench-scale collimated beam studies, the study will determine the impact of high levels of turbidity, algae, and TOC on the inactivation of pathogens such as Cryptosporidium, Giardia, and MS-2 coliphage. Preliminary results indicate a small drop in efficiency over time (attributed to the drop in lamp output), and good stability of the sensors.

This pilot study was recently completed. Final results should be available via final report, publications and conferences by fall 2001.

Another major AWWARF study, titled "Inactivation of pathogens by innovative UV technologies" was recently started. In the study, seven different units, representing five different UV manufacturers, are being tested at three different sites: Atlanta, GA; Austin, TX; and Orem, UT. The study involves long-term piloting of UV disinfection units, either medium-pressure or low-pressure high output units, and will run for approximately 12 months. Preliminary results of this study should be available by mid 2001.

Many additional pilot studies will follow these initial studies. Noteworthy is a study that will be partially funded by the American Water Works Service Co. (AWWSC), the Pennsylvania-American Water Company and Calgon Carbon Corporation. The project, titled "Full-scale evaluation of ultraviolet technology for disinfection of water," will consist of the continuous testing of a 4 X 1 kW Sentinel medium-pressure UV system for the duration of one year. The pilot study will take place at the Hays Mine water treatment plant in Pittsburgh, PA.

About the Authors:

Daniel R. Brooks serves as Sentinel Product Manager for Calgon Carbon Corporation. He has been on staff since 1989 and has worked extensively with drinking water treatment. Gary Van Stone serves as Marketing Director for Calgon. He joined the company in 1969 and has spent most of his career working in the drinking water treatment market.