UV System Features "Cooled by Configuration" Design

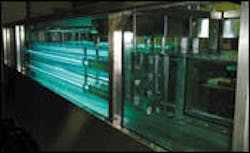

Suntec Environmental has introduced the LPX500, a high output, low pressure, parallel flow, modular UV system. The lamps use a rapid start configuration for maximum on/off performance and continuous heat for maximum dimming and energy conservation.

The company's patented ballast technology uses high frequency electronic ballasts to power each lamp and optimize system performance. The "cooled by configuration" design involves mounting the ballasts in the effluent stream, thereby eliminating the need for special cooling systems, enclosures or buildings. The system also features The Scrapper, a non-chemical automatic cleaning system.

Compact power distribution centers (PDC's) save space and use a modular design for maximum flexibility in meeting custom requirements. The PDC acts as a central location for system control, monitoring and alarming. It contains a control card and lamp rack control modules (LRCM) that provide power and indication for up to eight lamps. Remote/Local switches are located at each PDC for a choice of operating modes.

The LPX500 comes in open channel configurations that are suitable for medium to large wastewater treatment plants. In addition to new installations, systems can be retrofitted into existing effluent channels and chlorine-contact chambers. The equipment is sold complete with all necessary cables, controls, monitoring and alarm equipment, and is ready for installation and operation.

A basic system provides self-diagnostics, individual lamp status indication and an elapsed time counter. A UV intensity monitoring system monitors lamp output, absorption of UV light and fouling of quartz sleeves. The modular design uses racks that support two to eight lamps each. Lamp racks are installed side by side in the open channel to form lamp banks. Effluent flows through the lamp banks parallel to the lamps, with an appropriate level of effluent being maintained over the lamp banks by a weir or automatic level gate at the end of the channel.

The UV system is comprised of lamp racks with lamps, quartz sleeves and ballasts; automatic cleaning system; power distribution centers with operator station; UV sensor; automatic level control weir or level gate; spare parts; a UV faceshield and all necessary interconnecting cables, along with a host of accessory components. The system is installed in an open concrete channel (supplied by others).

Options include the addition of an on-line UVT analyzer and monitor; a system control center; a service rack to simplify routine lamp replacement and a photometer to measure UV transmittance for optimizing system performance. A hardwired remote enable relay is included in UV disinfection systems without PLC's that are associated with Sequential Batch Reactor (SBR) wastewater treatment processes. This feature allows the lamps to warm up prior to the decanting of the wastewater. PLC based UV disinfection systems incorporate remote-enable capability in the software.

Booth 5529