Membranes Will Help WWTP Exceed State Discharge Standards

By Scott Blair and Cory Schneider

As development and population continued to increase in the northern Michigan community of Traverse City, administrators turned to the community for input and support in expanding the area's wastewater treatment plant (WWTP).

Environmental stewardship and community spirit formed the cornerstones for a series of public forums that revealed a strong desire from residents to achieve effluent discharge standards that were more stringent than those specified by the Michigan Department of Environmental Quality (DEQ). The meetings also showed that residents disapproved of expanding the footprint of the current WWTP because it would mean giving up an adjoining portion of recently improved city parkland to accommodate the new development.

Traverse City is a modestly sized community of about 15,000, well known for the natural beauty that surrounds the city, which contributes to a well-developed, four-season tourism and recreation industry. In addition to Traverse City, the wastewater treatment plant also serves parts of Grand Traverse and Leelanau Counties, meaning that well over 45,000 people send wastewater to the plant.

Citizens asked their management team and wastewater treatment consultants to seek out a technology that would not only preserve water quality, but even improve it. The target objectives that were set for the effluent were 4 mg/L BOD, 4 mg/L TSS, 1 mg/L ammonia nitrogen, and 0.5 mg/L phosphorus. This is significantly lower than the DEQ requirements of 25 mg/L BOD, 30 mg/L TSS, 11 mg/L for ammonia nitrogen, and 1 mg/L for phosphorus.

The challenges that the project team faced were not only how to achieve these objectives, but how to achieve them within the footprint of the existing plant. It was impossible to expand the current footprint, since the plant is bordered by Boardman Lake to the south, Boardman River to the west, and developed parkland and business areas on the remaining two sides.

The project team, led by the engineering and construction firm CH2M Hill, of Englewood, CO, began designing a solution that would meet the current expansion needs and continue to provide high quality effluent well into the future.

Membrane Bioreactor (MBR) technology was chosen as the best available solution to enable the WWTP to efficiently and cost-effectively achieve its goals. MBR systems combine membrane filtration technology with biological treatment and are ideal to upgrade existing facilities that face expansion and effluent quality challenges, yet are unable to procure land for the expansion. MBR systems can often leverage a great deal of existing infrastructure and can double or even triple treatment capacity within the same footprint.

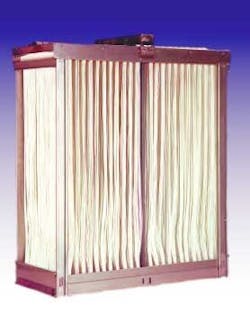

Zenon Environmental Inc. was selected to provide the ultrafiltration membranes and associated equipment for the MBR system. The Traverse City MBR incorporates reinforced, hollow-fiber membranes that are immersed directly into the mixed liquor and draw treated effluent into the fiber using a gentle suction. The membrane acts as a physical barrier, preventing suspended solids and pathogens from being released in the final effluent. The process of filtering wastewater with membranes is highly automated, and since particles and pathogens are physically removed from wastewater, municipalities often use fewer chemicals to disinfect treated water.

MBR systems can also lead to considerable capital cost savings, since the need to purchase additional property can be eliminated or delayed for many years. This benefit enabled Traverse City to increase the capacity of its WWTP, and to achieve a higher quality of effluent, without expanding the facility onto neighboring land or building an entirely new facility at a different location.

Construction of the upgrade is nearly complete, and facility components are scheduled to startup throughout 2004. The upgrade will increase the plant's capacity from an average daily load of approximately 14,178 lb/day of BOD to 20,200 lb/day of BOD. Flow capacity will be 8.5 mgd, with peak flow capacity of up to 17 mgd. The plant will treat maximum monthly loads of 20,200 lb/d BOD, 36,500 lb/d of total suspended solids (TSS), and 2,200 lb/d of ammonia.

A 450,000 gallon tank, with eight equally sized compartments, will contain the membrane equipment. Mixed liquor will be equally distributed among each compartment. Nearby, a building will contain five membrane air scour blowers, eight permeate pumps, and three 10,000 gal/min mixed liquor recirculation pumps. Back pulse pumps will also be housed in this building and will force treated effluent back through the membranes to remove particles that may be trapped on the surface of the membrane. The back pulse process occurs at regular intervals and is completely automated.

Traverse City will be the largest municipal wastewater treatment plant in North America using MBR technology. The $30 million expansion cost includes integration of the MBR membrane equipment into a biological nutrient removal (BNR) system, new fine screens, an expansion of the process used to thicken waste-activated sludge (WAS), an increase to the aeration blower capacity, construction of an additional anaerobic digester, expansion of the biosolids storage facility, and other minor plant improvements.

The success of this project shows that citizens and city leaders can work together to balance societal, economic and environmental interests for a positive effect on the wellbeing of all community members. Clean water will benefit all residents and businesses of Traverse City and the surrounding area, ensuring that residents and visitors continue to enjoy the sandy shores and crystal clear waters for years to come. WW

The project team, led by the engineering and construction firm CH2M Hill, of Englewood, CO, began designing a solution that would meet the current expansion needs and continue to provide high quality effluent well into the future.

Membrane Bioreactor (MBR) technology was chosen as the best available solution to enable the WWTP to efficiently and cost-effectively achieve its goals. MBR systems combine membrane filtration technology with biological treatment and are ideal to upgrade existing facilities that face expansion and effluent quality challenges, yet are unable to procure land for the expansion. MBR systems can often leverage a great deal of existing infrastructure and can double or even triple treatment capacity within the same footprint.

Zenon Environmental Inc. was selected to provide the ultrafiltration membranes and associated equipment for the MBR system. The Traverse City MBR incorporates reinforced, hollow-fiber membranes that are immersed directly into the mixed liquor and draw treated effluent into the fiber using a gentle suction. The membrane acts as a physical barrier, preventing suspended solids and pathogens from being released in the final effluent. The process of filtering wastewater with membranes is highly automated, and since particles and pathogens are physically removed from wastewater, municipalities often use fewer chemicals to disinfect treated water.

MBR systems can also lead to considerable capital cost savings, since the need to purchase additional property can be eliminated or delayed for many years. This benefit enabled Traverse City to increase the capacity of its WWTP, and to achieve a higher quality of effluent, without expanding the facility onto neighboring land or building an entirely new facility at a different location.

Construction of the upgrade is nearly complete, and facility components are scheduled to startup throughout 2004. The upgrade will increase the plant's capacity from an average daily load of approximately 14,178 lb/day of BOD to 20,200 lb/day of BOD. Flow capacity will be 8.5 mgd, with peak flow capacity of up to 17 mgd. The plant will treat maximum monthly loads of 20,200 lb/d BOD, 36,500 lb/d of total suspended solids (TSS), and 2,200 lb/d of ammonia.

A 450,000 gallon tank, with eight equally sized compartments, will contain the membrane equipment. Mixed liquor will be equally distributed among each compartment. Nearby, a building will contain five membrane air scour blowers, eight permeate pumps, and three 10,000 gal/min mixed liquor recirculation pumps. Back pulse pumps will also be housed in this building and will force treated effluent back through the membranes to remove particles that may be trapped on the surface of the membrane. The back pulse process occurs at regular intervals and is completely automated.

Traverse City will be the largest municipal wastewater treatment plant in North America using MBR technology. The $30 million expansion cost includes integration of the MBR membrane equipment into a biological nutrient removal (BNR) system, new fine screens, an expansion of the process used to thicken waste-activated sludge (WAS), an increase to the aeration blower capacity, construction of an additional anaerobic digester, expansion of the biosolids storage facility, and other minor plant improvements.

The success of this project shows that citizens and city leaders can work together to balance societal, economic and environmental interests for a positive effect on the wellbeing of all community members. Clean water will benefit all residents and businesses of Traverse City and the surrounding area, ensuring that residents and visitors continue to enjoy the sandy shores and crystal clear waters for years to come.

About the Authors:

Scott Blair, of OMI Inc., is Project Manager for the Traverse City Wastewater Treatment Plant. He has a BS in Biology from the University of Michigan. Cory Schneider, M.A.Sc., P. Eng., is a Process Engineer in the Municipal Division of Zenon Environmental Inc., responsible for process design and optimization of ZeeWeed membrane processes for municipal wastewater treatment applications.