Turbidity Measurement Key to Drinking Water Treatment

By Tim Schilz

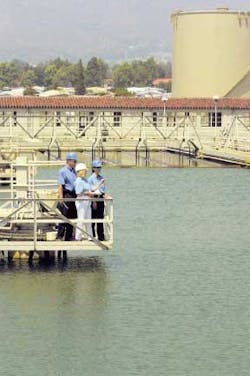

The measurement of turbidity, the relative clarity of water, is a vital indicator of water quality. As such, turbidity is a critical measurement for drinking water plants both for compliance with USEPA or international regulations, and for securing high-quality water for consumer protection.

More stringent EPA regulations, such as the current Surface Water Treatment Rules (Long Term 1 Enhanced Surface Water Treatment Rule or LT1ESWTR), mean that measuring turbidity is not an option – it's a requirement — for today's drinking water treatment plants. However, there are several important aspects of turbidity measurement that water plant operators must keep in mind when selecting a turbidimeter that will best suit their needs.

Turbidity can be affected by the presence of microscopic particles such as clay, silt and other fine undissolved matter. These microscopic particles, even at a very low concentration, can promote microorganism growth. This growth can harbor pathogens and also inhibit the chlorination process that helps disinfect and maintain purified drinking water in an area – thereby creating potential community health hazards.

A turbidity system incorporates three elements: an analyzer, a sensor and a sampling chamber. Light directed by the sensor assembly is passed through the sample and is scattered by suspended particles in the sample. This scattered light is detected by the sensor's photodiode at a 90-degree angle to the incident beam, converted into a turbidity signal and read by the analyzer. These turbidimeters are also known as nephelometers, hence the units of measure for these devices is known as nephelometric turbidity units or NTUs. The more suspended particles there are in the sample, the more light will be scattered, and the higher the NTU reading will be.

Consumer Protection

Despite time-tested filtration and disinfection techniques and procedures plants use to secure high-quality water, many conditions surrounding today's public utilities complicate issues related to consumer protection. Aging water plant and distribution system infrastructures present challenges to the prevention of waterborne disease. Outmoded or poorly maintained electronic monitoring systems make detection of serious contamination events problematic. Water distribution systems get larger but utility staffs and budgets shrink. So while high-quality water may be produced, employing on-line accurate turbidity measurement throughout the water treatment process has become a necessary critical step to ensuring the quality of the water supply in compliance with strict regulatory standards before distribution to consumers.

Continuous, On-line Measurement

More stringent regulations and increasing public health concerns ensure that the days of grab-sample analysis are over. In order to protect against contamination risks, turbidity must be measured continuously, as the turbidity value can change on a weekly, daily or hourly basis. The key to a successful water quality system in today's environment is using the latest in approved monitoring technologies to measure changes in the water filtration operation, which can only be evaluated over time. Changes in turbidity must be watched very carefully as to immediately detect upset conditions and possibly signal the need for a change in the water treatment process.

One example of an on-line turbidity monitoring system is the Rosemount Analytical Clarity II™ turbidimeter from Emerson Process Management. The meter is designed to continuously monitor turbidity levels on-line to ensure the protection of water quality.

The turbidimeter is offered in either single-channel or dual-channel configurations. The dual-channel option reduces costs for plants that require numerous turbidity sensors in multiple points in the water filtration process.

The company's patented technology offers ease of use and simple calibration. The system is delivered "plug and plumb" with no additional sensor wiring required. This technology is also backed by a two-year warranty and Emerson Process Management's worldwide customer service and support.

Final Thought

Drinking water plants do not have a choice about measuring turbidity – it is a critical measurement to ensuring safe and high-quality drinking water – but important factors such as ease of use, simple maintenance requirements, dual-channel capabilities and long-term customer service and support should be considered when water treatment plant operators are selecting quality turbidity measurement systems.

About the Author:

Tim Schilz, OEM Market Manager, Emerson Process Management, Rosemount Analytical, Liquid Division, has been active in the drinking water industry for over 14 years. He has served on AWWA (American Water Works Association) and WEF (Water Environment Federation) committees, both nationally and on local section levels and is also a Village Trustee and Water Commissioner serving Brown Deer, Wisconsin.