Membrane Thickening Helps Improve Performance, Reduce Polymer Use

By Bryen Woo

A relatively new controlled aerobic digestion process that uses membranes to pre-thicken waste activated sludge offers operational, economic, and process benefits which include the ability to thicken sludge up to 3% solids concentration without the use of polymers and produce a reusable quality permeate.

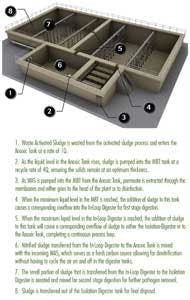

The Pre-thickened Aerobic Digester using a Kubota Membrane Thickener (P.A.D.®-K) process was developed by Ovivo. This process is suitable for treating waste activated sludge (WAS) from many biological processes such as membrane bioreactors (MBR) and conventional processes such as sequencing batch reactors (SBR), extended aeration, and oxidation ditches.

There are up to 16 operating P.A.D.®-K installations in the United States with several more in construction.

The process is suited for Class B stabilization applications and provides continuous thickening, allowing for operations to be independent of wasting schedules from the liquid process. Thickening of WAS with membranes significantly reduces the volume of sludge resulting in less volume required for process tanks. Because tank sizes are smaller and process volume is less, energy requirements are reduced due to lower air flow demands.

Thickening with membranes is independent of the WAS settling characteristics in contrast to a standard aerobic digestion process using decanting, where thickening performance can fluctuate greatly.

Reusable Quality Permeate

High nutrient concentrations in recycled water from a solids handling process are widely recognized as a leading cause for high nitrogen and phosphorus loadings. In order to remove phosphorus and nitrogen from the effluent, chemical addition of alum or ferric chloride is required which can add substantial cost and can increase sludge loads up to 40%.

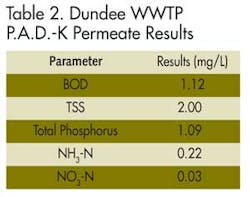

The permeate produced from a P.A.D.®-K system contains a very minimal amount of total nitrogen, total suspended solids, and phosphorus and if recycled to the head of the plant will protect the effluent quality of the BNR biological process without requiring chemical addition. The permeate can also be sent directly to disinfection or combined with the plant effluent.

The system uses nitrification and denitrification processes to remove nitrogen in both the solid and liquid phase. The process also can minimize the release of the three forms of phosphorus: inorganic phosphorus, polyphosphorus, and organic phosphorus.

The continuous nitrification and denitrification sequencing allows excellent pH control, preventing the dissolution of inorganic phosphorus. Polyphosphorus accumulating organisms (PAOs) can store carbon compounds as a source of energy in the absence of oxygen or nitrate, which are common energy sources in biological processes. The storage of carbon compounds by PAOs results in a polyphosphorus release. The incoming WAS into the Anoxic Tank provides a fresh carbon source for PAOs to release polyphosphate following the exhaustion of nitrate, which also occurs in this tank. The aerated MBT tank, where permeate is collected, allows for the PAOs to grow and uptake the released polyphosphorus while burning their stored carbon reserves resulting in reduced phosphorus levels in permeate.

PAO decay causes organic phosphorus release into the permeate due to substantial biomass destruction in the P.A.D.®-K process. However, organic phosphorus release in permeate is minimal since Van Haandel and Van der Lubbe found the decay rate of PAO is approximately six times slower than non-PAO bacteria, and there are approximately twice as many non-PAO bacteria than PAO in a typical biomass. Although non-PAO bacteria are more common in a biomass and have a faster decay rate they contain approximately 15 times less polyphosphorus than PAO bacteria (Van Haandel and Van der Lubbe, 2007).

Case Study

The wastewater treatment plant at Dundee, MI, required a process that could provide class B sludge for subsurface injection which wouldn't negatively impact the plant's BNR activated sludge system. Since sub-surface injection timing was limited due to regular heavy snowfall, the facility was required to have a holding time of approximately 180 days with very limited sludge hauling.

In order to increase the sludge retention time to 180 days, Arcadis Engineers integrated the P.A.D.®-K process with existing aerobic digester tanks. Only a new membrane thickening tank (MBT) was added.

After implementing the process, the plant was able to thicken from 2.5% to 5.5% solids prior to the season when sub-surface injection was not possible, all without the use of polymers. Due to the improved performance, the 180-day storage objective was achieved and the facility was able to limit sludge hauling to twice a year. Direct results from this upgrade allowed the plant to double its capacity to 1.2 mgd, while reducing sludge disposal costs by nearly 40%.

The high quality permeate from the P.A.D.®-K is rerouted to the head of the plant without compromising the performance of the BNR activated sludge process. This type of permeate quality has been sustainable throughout the entire course of operation at Dundee WWTP.

About the Author: Bryen Woo, PE, is Aeration/Aerobic Digestion Product Manager at Ovivo USA. He may be contacted via email at [email protected]

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles