Study Examines Compression Gradient in Compressible Media Filter

The Compressible Media Filter, CMF, is a relative newcomer to the filtration market. It has been theorized that when a CMF bed is in its “compressed-for-filtering” state, there exists a difference between the amount of media compression nearest the point of compression verses that at the opposite end of the media bed. This difference in compression is referred to as a “compression gradient”.

The existence of such a compression gradient is not only mathematically and scientifically interesting; it has significant implications for filtering. Operationally, its existence would transform the CMF from a deep bed mono-filter into a filter that combines the ease of operation of a depth mono-filter with the removal characteristics of a multi-media filter -- without the de-stratification problems that are inherent with multi-media filters during back washing.

A technical study, performed under laboratory conditions, has been completed to investigate this hypothetical compression gradient unique to the Compressible Media Filter.

As one of its product offerings, Schreiber LLC manufactures a unique type of CMF filter known as the Fuzzy Filter®. Since this filter uses a highly porous and compressible synthetic fiber material that offers the perfect example of a CMF for compression gradient testing, it was employed as the test media for this study.

The filtration bed of the Fuzzy Filter is composed of a multitude of roughly spherical balls of synthetic fibers. These fibers are bound together at the center of each ball by a metal binder clip. Each sphere, in its uncompressed state, is about 1.25 inches in diameter. This compressible media, with a porosity of 88% to 90%, has a density that makes it just slightly heavier than water and produces an uncompressed filter bed that exhibits a porosity of roughly 92% to 94%.

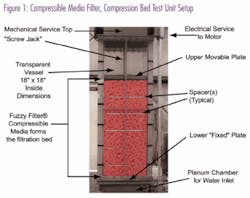

The test setup for the compression gradient study is shown in Figure 1. As can be seen in the figure, the vessel was constructed of a transparent high impact plastic to allow total visibility during the study.

The transparent portion of the test vessel was 60" in height and was bounded on the lower end by a perforated plate, which was fixed in place. A vertically moveable perforated plate, used to compress the bed, served as the upper limit.

An actuator mounted on top of the vessel controlled the position of the upper moveable plate and supplied the compressing force. Also, evident in Figure 1, are the five rigid plastic sectional spacers used to create six identifiable sections of the media bed.

Prior to compression, the position of each of the sectional spacers relative to the lower plate was recorded as the “base” or “uncompressed position”. The testing procedures involved compressing the media bed, measuring the overall compression of the filter bed, and then measuring the change in the distances between the sectional spacers. From this raw data, the percentage of compression for each of the individual sections of the media bed was computed and related to the overall change in compression for the entire media bed.

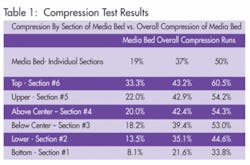

The results of one run of these compression tests are recorded in Table 1. The compression levels of 19%, 37% and 50% that were imposed on the overall media bed are shown as columns in Table 1.

A compression gradient was determined to exist with the top section being compressed roughly twice as much as the bottom section. For example, in Table 1, at an overall compression of 50%, the top section experienced a compression of 60.5% while the bottom section was only compressed by 33.8% Such results are logical, since the media bed was compressed from the top down.

Conclusions

The evidence from the study provides documented proof of the existence of the theorized compression gradient described at the outset. The study strongly supports the existence of a compression gradient across the filter bed as opposed to a uniform compression throughout the filter bed. Every compression test performed during the study produced a compression gradient across the filter bed similar to that recorded in Table 1.

Additionally, the evidence from the study showed that the direction of the compression gradient was consistent. The greatest compression always occurred at the top of the filter bed, nearest the compressing upper moveable plate. Conversely, the least compression constantly appeared at the bottom of the filter bed - farthest from the upper moveable plate.

The magnitude of the compression gradient was also shown to be significant by the results of the study. In all test runs, the uppermost section of media showed a compression of no less than 180% of that experienced by the lowest section of the filter bed. Consequently, the media in the top section of the test bed was compressed almost twice as much as the media in the bottom section of the filter bed.

By arranging the filter bed such that higher compression and hence lower porosity occurs at the effluent end of the filter bed, the performance of the CMF filter can be enhanced. The larger openings (i.e. higher porosity) that occur at the influent end, as a result of such an arrangement, allow the finer particles to more deeply penetrate the media prior to capture. Consequently, particles will be captured throughout the filter bed resulting in a higher storage of solids, longer run times and progressively finer straining mechanisms as the solids move through the media bed.

Fuzzy Filters are designed to operate in an upflow mode which does take advantage of these unique characteristics.

In an analogy with granular media filters, the foregoing conditions allow the Fuzzy Filter, which is a mono-filter, to exhibit the solids removal characteristics of a multi-media bed filter without the washing and de-stratification problems seen in multi-media filters.

Following this multi-media analogy to its logical theoretical conclusion, a case could be made that, at least for the compressible media filter that was investigated by this study; the CMF exhibits the characteristic advantages of a theoretical “infinitely-variable-media” filter.

The study was conducted by The Resource Consulting Group of Hoover, AL. Principal investigator was William F. Foreman, III, PE, a registered Professional Engineer. He may be contacted via e-mail at [email protected]. WW

Schreiber is an exhibitor at the WEFTEC.09 event and can be found at Booth No. 3803