Chordal-Path Flowmeters Meet Challenge of Large UV Systems

By Guy Miller and John Trofatter

A key element in successful implementation of an ultraviolet (UV) disinfection system is proper control and operation of the UV lamps. The intensity and operational period of a lamp bank is typically a function of the specified disinfection requirements and flowrate. Meeting the disinfection requirements while maximizing the efficiency of the UV system is predicated upon accurate and repeatable flow measurement.

null

The complex piping of a large UV system (large being defined herein as 30 inches or greater in pipe diameter or channel width) provides very challenging hydraulic conditions that can impact the accuracy and repeatability of a flowmeter. It is critical to install a flow measurement technology that can operate as specified under these difficult hydraulic conditions in order to achieve the desired UV system performance.

Traditional flow measurement technologies are often not suitable for the unique challenges presented by large UV disinfection systems. These can include severely distorted flow profiles due to the complex piping of the system and the limited available space to install a flowmeter.

Multiple chordal-path transit-time flowmeters can be a suitable alternative for UV disinfection systems. While not as well known to flowmeter users in the water and wastewater industries, this type of transit-time flowmeter has been in use for many years, but generally limited to the most difficult installations with complex hydraulics and the need for high performance.

The multiple chordal-path arrangement, and the numerical integration techniques used, allow this type of flowmeter to use much greater velocity profile resolution for numerical integration and is neither Reynolds Number nor sonic velocity dependent. These are the primary performance limiting factors of the diametrical-path transit-time flowmeters. Unlike magnetic and venturi flowmeters, chordal-path transit-time flowmeters require relatively short end-to-end distance for installation addressing a critical issue for large UV systems. The chordal-path method also allows the flowmeter to measure flows in open channels as well as full pipes making it well suited for the various installation requirements of UV systems.

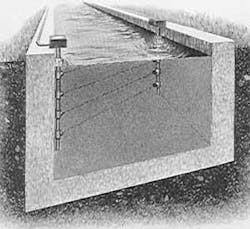

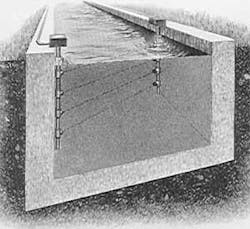

Multiple chordal-path transit-time flowmeter installations can include both internally mounted and feedthrough (through-wall) transducers depending on the access to the measurement section. A typical multiple chordal-path transit-time flowmeter consists of two or four chordal elevations depending on the accuracy that is required. A typical two elevation chordal transit-time flowmeter will have a system uncertainty of ± 1.5-2.0% and a typical four elevation chordal transit-time flowmeter will have a system uncertainty of ± 0.5-1.0%. It is important to note that these are anticipated installed accuracies, not accuracies achieved in a laboratory under ideal flow conditions. Figure 1 shows the general configuration of a multiple chordal-path transit-time flowmeter in both a closed full pipe application and a variable depth open channel application.

In Figure 1, the upstream transducers are offset at a 45 degree angle across the pipe to their downstream mating transducer. This angle can be changed to 65 degrees if external access is limited (reducing the overall end-to-end distance even further). In an application where there is limited upstream straight approach to the flow measurement section, crossed-paths can be installed at each elevation to correct for the effects of cross-flow. Cross-flow occurs due to an upstream disturbance in the piping configuration (elbow, bifurcation, etc.) where the main flow component is no longer axial (not parallel to the pipe wall). When cross paths are installed in the presence of cross-flow, one plane will be bias high and the opposite plane will be bias low by the same magnitude of its crossed plane. The two acoustic paths installed at the same chordal elevation are averaged with a resulting net bias of zero.

The transit-time principle measures an average velocity across the pipe at a given chordal elevation. Figure 2 shows the velocity calculation based on the travel time of the sound pulse, the liquid sonic velocity, the acoustic path length, and the acoustic path angle. As shown, when the upstream and downstream travel times are combined to solve for the average velocity at a particular elevation the sonic velocity variable cancels. This is important to note because a multiple chordal-path transit-time flowmeter is not dependant on the liquid sonic velocity and can be applied to applications with drastic changes in the temperature.

As previously mentioned, there are a number of variables that determine a flowmeter’s overall system uncertainty (or accuracy). In a multiple chordal-path transit-time flowmeter system, these uncertainties are defined by four major components: the individual velocity measurements; cross-section area measurement; velocity integration (average velocity calculation); and random error. Typically the uncertainty of the velocity measurement and random error components are second order effects. The area measurement uncertainty is typically a fixed value and is based on the pipe diameter measurements taken during the installation. The largest contributor and most variable component to the overall uncertainty of a multiple chordal-path transit time flowmeter is the flow profile integration uncertainty.

In a four chordal-path elevation transit-time flowmeter, the acoustic chords are placed at ± 18 and 54 degrees with respect to the horizontal centerline of a pipe in full pipe applications. The integration technique is called the Jacobi-Gauss Integration Method (or Chebyshev Method). Computational fluid dynamics (CFD) analysis has been used to estimate the integration uncertainty of this method over a wide range of velocity profiles (from fully developed symmetrical profiles to highly disturbed velocity profiles). These analyses and previous field experience has shown that the uncertainty of the Jacobi-Gauss integration is in a range of ± 0.2% to 1.2%. As such, when a multiple chordal-path transit-time flowmeter is installed in a worst-case hydraulic location, its maximum overall uncertainty will be better than ± 1.5% for a four elevation chordal transit-time flowmeter. Therefore, even in the presence of highly disturbed velocity profiles, a multiple chordal-path transit-time flowmeter can perform accurately.

As the application of large UV disinfection systems continues to grow, the need for a viable flow measurement technology to address the challenges presented by these systems becomes more critical. The unique characteristics of the multiple chordal-path transit-time flow measurement technology enable a UV system to achieve the goal of assured continuous disinfection while maximizing the system’s throughput and efficiency. WW

About the Authors:

Guy Miller, P.E., is Engineering Manager at Accusonic Technologies. John Trofatter is General Manager for Accusonic Technologies