Assessing Disinfection Systemsv for Recycled Water Project

By Nicola Fontaine, Chris Cleveland, Ricky Gutierrez, and Mike Britten

The disinfection of recycled water for reuse is becoming more common nationwide as water supplies are impacted by drought and water demands of an ever-increasing population. To protect public health, recycled water disinfection technologies must be capable of meeting or exceeding the water quality standards set forth by the state in which the project is located. These standards vary by state, disinfection technology, as well as by the recycled water application.

Selection of a disinfection technology has become increasingly complicated with the addition of advanced technologies, changing regulations, and new potential applications. Utilities and consultants often have to analyze the effectiveness, benefits, and economics of disinfection alternatives to aid in selection of a technology suitable for a specific application.

Historically chlorine has been used, and more recently in-channel UV systems. While both are still options to be considered, other options are now available that can reduce footprint, energy, capital and O&M costs, and integrate more readily into the overall recycled water treatment train.

Economic analysis of disinfection technologies is specific to the site, upstream treatment process effluent quality, and the intended application of the recycled water. Thus, identifying the goals and relative importance of the benefits and advantages for the specific application early is critical in evaluating alternatives.

A selected technology must first protect public health and second balance the facility needs and requirements, recycled water rates, and cost of consumables (power, chemicals, replacement parts). The following case study from a utility in Northern California shows the cost impact of site-specific attributes and treatment goals.

Case Study

In California, Title 22 of the California Code of Regulations governs recycled water treatment and water quality requirements. Specific to virus disinfection, Title 22 requires that a disinfection process, when combined with filtration, inactivates and/or removes a minimum of 5-log poliovirus in wastewater. The technologies evaluated in this case study have all received Title 22.

This study was conducted to determine the most suitable disinfection technology to be placed after tertiary membrane filtration at an existing WWTP in Northern California for a new 4 mgd unrestricted irrigation recycled water facility.

The technologies evaluated included the Aquionics InLine 18000+ in-vessel medium pressure ultraviolet light (UV) system, a proprietary ozone system (HiPOx) by Applied Process Technology, and a pasteurization-based process by Pasteurization Technology Group. Evaluation of each technology was based on treatment efficacy, capital cost, life cycle costs, footprint, ease of integration into the existing plant, contaminant applicability (i.e., anything removed beyond Title 22 requirements), required ancillary facilities, complexity, safety, flexibility, and any other identified benefits.

While many other Title 22 approved technologies exist for recycled water (e.g., medium and low pressure open channel UV, low pressure in-vessel UV, and microwave UV), due to site space constraints and the desire to maintain the available pressure head from the pressurized tertiary membranes, these three technologies were selected for further analysis.

Conceptual designs for the three disinfection technologies were developed based on integrating the 4 mgd recycled water facility into an existing space-limited WWTP. Design criteria for the disinfection technologies were based on the anticipated membrane effluent quality (low turbidity and total coliforms) and the Title 22 approved operating parameters and design requirements.

UV Disinfection

Of the three technologies evaluated, UV disinfection is most familiar for wastewater treatment applications. The design criteria of the medium pressure in-vessel UV system was based on the 2003 Ultraviolet Disinfection Guidelines for Water and Water Reuse, published by the National Water Research Institute (NWRI) and American Water Works Association Research Foundation (AwwaRF). The Aquionics reactor, based upon testing by Carollo, has been approved by the California Department of Public Health (CDPH) for recycled water disinfection. Post membrane filtration currently requires a UV dose of 80 mJ/cm2 and a design UV transmittance of 65 percent. The medium-pressure in-vessel system has the added benefits of a small footprint, minimal operator attention, and no known formation of disinfection byproducts.

HiPOx

While the use of ozone is commonplace for potable water applications, the use of ozone for wastewater disinfection is scarce. For this project, the HiPOx system was evaluated. This system provides the benefits of a small footprint, minimal operator attention, reduction in chlorine dose for residual due to oxidation of organics, and the ability to destroy/inactivate contaminants of emerging concern in addition to pathogens. The HiPOx system, based upon testing by Carollo, has been approved by the CDPH for recycled water disinfection.

null

HiPOx systems are commonly used for taste and odor, disinfection, and remediation/destruction of inorganic and organic compounds. In remediation applications ozone and hydrogen peroxide are injected into the water stream generating hydroxyl radicals, which then oxidize contaminants. For wastewater, the addition of hydrogen peroxide is not needed, as radicals are readily formed during the addition of ozone to wastewater.

The system evaluated for this case study was based on injecting ozone only but maintaining the ability to add hydrogen peroxide in the future. The system evaluated is skid mounted and consists of a serpentine contactor with multiple injection points for ozone and hydrogen peroxide. The HiPOx system was designed based on an applied ozone dose of 6.5 mg/L and a 1 mg-min/L contact time. To meet the required contact time after the injection of ozone, a second serpentine contactor was included in the conceptual design downstream of the HiPOx skid.

Significantly, the existing WWTP’s pure oxygen system could be used to provide oxygen to the HiPOx system for ozone generation. This would reduce the annual operation costs and overall system footprint by removing the liquid oxygen (LOX) tank from the conceptual design and eliminating LOX deliveries.

Pasteurization

Pasteurization, the process of applying heat to a substance to inactivate microorganisms, is standard practice in the food industry and has also become accepted practice in sewage sludge processing, with the goal of achieving Class A Biosolids standards. The pasteurization process involves using a turbine to produce exhaust heat that is then used to heat the water stream with heat exchangers to greater than 180 degrees F, achieving “flash pasteurization”. This technique is beginning to be applied for recycled water disinfection and, based upon testing by Carollo, has been approved by the CDPH. Pasteurization has an additional benefit: the sustainable use of waste heat. Should a WWTP be flaring digester gas or have a cogeneration system, the waste heat from these processes can be captured and used for disinfection at a minimal cost.

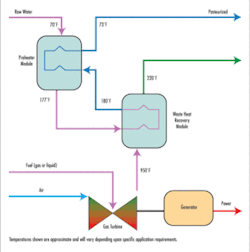

Figure 2 shows a process flow diagram of the pasteurization process. The first heat exchanger uses heat from pasteurized water to preheat undisinfected water from ambient temperature to ~177 degrees F. The second heat exchanger takes waste heat from the gas turbine exhaust to further elevate the water temperature to >180 degrees F. The treated effluent then returns to the first heat exchanger to preheat influent water and reduce the effluent temperature to just above ambient before discharge. The efficient energy transfer of the heat exchangers requires the second heat exchanger to only raise the water stream temp and additional 3 degrees in some cases.

The pasteurization system for the case study was designed based on a disinfection temperature of 180 degrees F and a 15 second contact time. It was assumed that all excess electricity produced by the turbine would be used on-site to reduce the annual electric bill of the WWTP. The turbine can use natural gas, digester gas, or a combination of the two to produce electricity and exhaust heat. The exhaust heat can be used for pasteurization and elsewhere in the WWTP.

Pasteurization has the added benefits of a small footprint, no chemicals, minimal operator attention, potential to reduce natural gas consumption with the use of digester gas, no known formation of disinfection byproducts, excess electricity to offset plant operating costs, and excess exhaust heat for plant use. One drawback is that the turbine would likely require an air emissions permit.

Life Cycle Comparisons

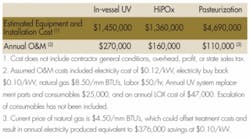

With the many similar advantages of the three technologies, cost was a significant selection criterion. The capital costs shown in Table 1 represent disinfection equipment and connecting piping only. The vendors supplied the treatment equipment costs and the additional capital costs were estimated based on the conceptual designs and specific site needs and constraints.

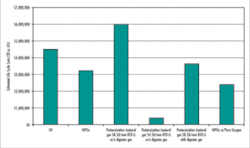

During the case study analysis, it appeared that the outcome of the cost analysis would change depending on the existing WWTP’s site attributes and constraints. A sensitivity analysis of the consumables for the systems was performed to show the potential cost savings that could be realized for existing WWTPs. Figure 3 shows the results of this analysis.

The first three bars show the estimated life cycle costs of installing each treatment system. All of the costs were based on a 20-year period and an interest rate of 6 percent. Under these assumptions HiPOx was the least expensive alternative for the WWTP and provided the greatest flexibility for advanced oxidation in the future if desired.

Since the time of this feasibility study natural gas costs have decreased from $8.50 to approximately $4.50/mm BTU’s. As shown in Figure 3 the life cycle costs of pasteurization are very sensitive to changes in natural gas costs, with pasteurization looking to be the least cost system at this low natural gas price. Additionally the life cycle costs of pasteurization can be reduced further if the existing WWTP had excess digester gas that could be used to power the turbine, thereby reducing natural gas consumption by 20 percent. This savings would be greater with the reduced natural gas cost.

Although the capital costs associated with pasteurization are higher than UV and HiPOx the life cycle costs of pasteurization can be less expensive due to the use of digester gas, natural gas costs, and the production of excess electricity. Additionally, turbines can be run solely on digester gas, which would provide a substantial annual cost savings. Depending on the cost of natural gas and electricity, pasteurization could provide cost neutral recycled water disinfection from back feeding electricity to the local power agency. If an existing plant has a turbine or cogeneration facility with enough excess heat for pasteurization the capital cost for pasteurization would be similar or less than UV and HiPOx.

As with pasteurization, the HiPOx system has the ability to integrate plant attributes that result in substantial cost savings. The last bar in Figure 3 shows the impact on HiPOx life cycle costs if the existing pure oxygen system at the WWTP had enough excess oxygen capacity to eliminate purchasing and storage of liquid oxygen. Benefits not reflected in the life cycle costs for this option include a reduction in footprint and plant chemical deliveries.

Conclusions

This type of alternatives analysis and the identification of site specific benefits and cost savings can aid utilities in selection of treatment technologies that not only protect public health but that can also provide a cost savings and/or added benefits specific to their applications.

As interest in recycled water increases due to tighter discharge requirements and scarcity of water resources treatment options are increasing to meet the demand. Advanced disinfection technologies provide utilities and consultants more options to meet the ever-increasing challenges for turning wastewater effluent into valuable recycled water. WW

About the Authors:

Nicola Fontaine is an Engineer/Scientist with Carollo Engineers in Sacramento, CA. She specializes in advanced disinfection and water reuse treatment technologies. She is a recognized expert in UV disinfection of water and wastewater. Chris Cleveland is an Associate with Carollo Engineers in Sacramento. He specializes in drinking water and advanced water, wastewater, and reuse treatment processes. Ricky Gutierrez is an Engineer with Carollo Engineers in Sacramento. He has provided a broad range of services for wastewater and recycled water projects. Mike Britten is a Partner with Carollo Engineers in Walnut Creek, CA. He has 34 years experience in master planning, design, and construction management of wastewater, water, and stormwater facilities.