Tried-and-True Technology Remains Relevant in Water, Wastewater Industry

By Michelle McNish

The water and wastewater industry also has its tried-and-true technologies. Today, municipal utilities have a greater variety of treatment alternatives than ever before. Many of the state-of-the-art technologies were not even available a generation ago when most of the water quality regulations and policies were crafted. There have been significant advancements made in both the understanding of advanced biological treatment and the development of treatment technologies necessary to meet new effluent requirements. However, as the industry becomes inundated with the latest and greatest in new technology, many of the tried-and-true, progressively improved technologies are becoming more relevant than ever.

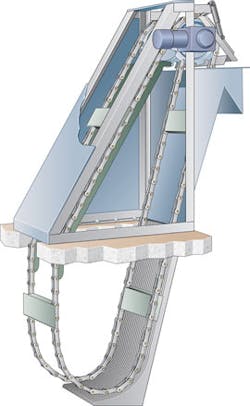

A key example of this is in the headworks, or preliminary treatment area, of wastewater treatment plants. Specifically, screening technology has seen an abundance of new product development, some of which has been necessary in order to meet the treatment requirements associated with the use of membranes. However, for the majority of treatment plants, conventional mechanical bar screens with open spaces of 1/4-inch or larger effectively meet the solids removal requirements. There is no shortage of mechanical screens to choose from, but one that stands out as having the longest history of successful operation is the catenary bar screen.

The catenary bar screen was originally developed in the 1950s for the city of New Orleans for screening ahead of its stormwater pump stations. Due to the unique requirements of the region -- with most of the area being below sea level -- the city required a screen that was simple to operate, easy to maintain, constructed of heavy-duty material, and that routinely had the ability to continuously remove large amounts of debris. With the success of the catenary screen for the New Orleans applications, the Galveston Corp of Engineers office soon adopted this type of screen for numerous stormwater pumping stations in southeast Texas.

One of the key features of the catenary bar screen that helped it achieve the original design requirements is the fact that it has no lower sprockets, which allows it to ride out over any obstructions that may occur on the bar rack, thus creating a "jam-free" operation. Also, this eliminates any maintenance below the top of the flow channel. While these were essential requirements for the original application of this type of screen, they are equally as important today when municipal economics require long-lasting equipment with minimal maintenance, simple automatic operation and non-proprietary replacement parts.

Although there have been many screens developed since the first catenary bar screen went into operation, it would be difficult to find one that better meets current economic and performance requirements, illustrating that in the water and wastewater market, the tried-and-true technology is oftentimes still the best.

About the Author: Michelle McNish is the president of E & I Corporation, a division of McNish Corporation, in Westerfield, Ohio. She is a member of the board of directors of the Water and Wastewater Equipment Manufacturers Association.

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles