Grit Removal: Why One Size Does Not Fit All

Grit casts a long shadow over wastewater treatment. It can be a silent menace, which, if not removed effectively at the headworks, interferes with downstream plant equipment, causing significant and costly damage.

Wastewater treatment plant (WWTP) operators are often frustrated with the inefficiency of their grit removal systems. However, faced with conflicting industry information, it can be daunting for engineers to fully characterize the behavior of grit specific to their plant.

The problem is clear enough: Grit abrades mechanical equipment and components. Downstream, it settles and can cause reduction in tank volumes such as primary clarifiers and digester and aeration basins -- ultimately reducing process efficiency. It often plugs pipes as well. The result: reduced plant performance or even failure, high maintenance bills, costly shutdowns, and early equipment replacement.

Separation Anxiety?

Relieving the "separation anxiety" of WWTP operators starts with establishing the facts about what grit arriving at a treatment plant is actually like and how it behaves -- separating fact from fiction about the size and composition of incoming grit. Only by understanding the shape, size distribution and settling velocity of the grit particles can a removal-efficiency target be established that is specific to the plant.

It sounds straightforward enough, but settling velocity is frequently overestimated. Conventional design guidelines target removal of grit larger than 210 microns, and grit particles are considered to be perfect spheres of silica sand with a 2.65 specific gravity (SG) settling in laminar conditions in clean water. This ideal assumption dates back to suggestions first proposed in the 1940s.

Recent surveys over a range of treatment plants and localities in the U.S. have confirmed the wide variation in particle settling velocity and the effects of SG, shape and organic material agglomerating with grit particles. These variations make a successful "one-size-fits-all" approach to grit system design impossible.

Advanced Grit Management

In response, Hydro International has pioneered the philosophy of Advanced Grit Management™, with a stated objective of 95%+ removal efficiency of particles in the 75-150 micron range and 85-95% efficiency of the total grit load entering a treatment plant. Key to this approach has been the intensive study of grit parameters and behavior and design of grit removal solutions with a small footprint, low headloss, low power use, and low operating costs.

The Eutek HeadCell

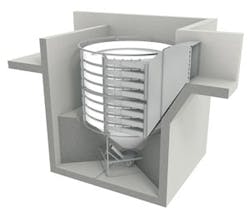

Considered the ‘next generation' of grit separation technology, Hydro's HeadCell® is a modular, multiple-tray, settleable solids concentrator that achieves high-performance removal of fine grit as small as 75 microns.

The HeadCell eliminates the inefficiencies of conventional forced vortex grit removal systems. Its unique stacked tray design optimizes the capacity for grit separation within a small footprint -- making it ideal for both new and retrofit applications. The HeadCell is best used with Hydro's washing and dewatering systems to guarantee the overall system efficiency.

Hydro International develops innovative solutions for cost-effective stormwater and wastewater management. Headquartered outside of Bristol, England, Hydro conducts operations in the United Kingdom, Ireland and the United States and worldwide through a combined network of licensees and distributors. For more information, visit www.hydro-int.com.

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles