Biological treatment

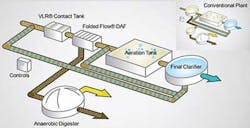

The Captivator™ System from Siemens combines two proven technologies to capture BOD that otherwise requires aeration energy to treat and converts it to biogas. It improves a conventional process by replacing primary clarification and separate sludge thickening with a modified contact stabilization process in front of a DAF. The system is comprised of a VLR® Aerated Contact Tank, which helps biomass absorb soluble BOD; a Folded-Flow® DAF that efficiently removes the majority of the Biomass and incoming SS; and an integrated control system that fine-tunes performance. In an anaerobic plant, up to 40% more biogas is generated, up to 40% less aeration energy is required, and up to 20% footprint and capital cost savings are possible.

Siemens Water Technologies

www.siemens.com