Dual Drive Pumps Ensure Water Pressure When Grid Goes Down

Down along the shores of Miami’s fashionable South Beach neighborhood, the operating slogan seems to be that “you can never be too rich or too thin.” When it comes to ensuring the water supply, however, a very different slogan applies - you can never be too redundant.

Recently, when undergoing an upgrade to its drinking water filtration systems, the City of Boca Raton, FL, installed new dual drive pumps so there would be no interruption in the water flow during an electrical outage.

“We now feel that no matter what happens, we are prepared to always pump adequate pressure to the citizens,” said Greg Essen, the city’s water plant superintendent.

Located on the Atlantic coast about 40 miles north of Miami, the City of Boca Raton employs a staff of just over 100 to provide water to its population of 75,000. The city draws its water from 51 wells and processes the water at its plant on Glades Road. The plant has the capacity to process up to 70 mgd, although the daily average is 42 mgd. The facility also includes a wastewater plant that processes 15.2 mgd and provides about 5 mgd in reclaimed water for irrigation. Five ground storage tanks store up to 23 million gallons, or about half a day’s supply, which means that there is little margin for error. The water plant must be kept operational or a shortage quickly develops.

Like other Florida cities, Boca Raton’s ground water comes from a shallow aquifer - about 100 to 200 feet - and has a very high level of dissolved organic material. While the water was safe for drinking, the organic material affected the water’s color and taste. That’s why the city began the process in the late 1990s of installing a new state of the art 40 mgd nanofiltration plant to supplement the 70 mgd lime softening system at the Glades Road Plant. The city hired Camp, Dresser and McKee (CDM) to design the facility. Poole & Kent Company was the prime contractor.

“There was a $48 million dollar budgeted cost and it went up to $50 million with change orders,” said Thad Buckley, senior project manager for Poole and Kent. “We finished the job in three years and the city is happy with how the facility has performed.”

Electrical Unreliability

At the time the filtration plant came on line in 2004, it was the largest nanofiltration facility in the world, with 8000 pressurized membranes.

Boca Raton was relying on electricity to power its main high service pumps to maintain the water pressure. Every area of the country has its own particular threats to the electrical supply and so it isn’t wise to rely on a single source of power for the pumps. In South Florida, there are several things which bring down the grid. One, of course, is the hurricanes which come though on a fairly regular basis. In 2005, Boca Raton lost power when Hurricane Frances dropped by for a visit. But less severe weather also poses a problem.

“During the summer in South Florida, thunder and lightning storms are prevalent in the afternoon showers,” Essen said.

Then there is the matter of high summer power consumption. The Glades Road Water Treatment Plant receives its electricity from Florida Light and Power under a peak shaving agreement. Under the agreement, the city gets its power at a discount, but FPL has the authority to cut off the electrical supply when demand is high.

To get around the uncertainties of the grid, the plant has its own diesel generating station to take over when grid power fails. But Essen knew from experience that relying on a single backup was far from adequate.

Keeping Up the Pressure

To address these issues, Essen pushed to move the city onto dual drive pumps. At the same time as the water treatment project, the existing pumps needed to be replaced in order to meet new water quality regulations.

“Under the new regulations, the contact time must be covered time; exposed filter time does not count,” Essen said. “Once the water goes through the filter and enters the clear well, the clock starts. We can no longer just pump directly from the clear well; we have to have that contact time covered.”

As a result, the pumps would have to be moved to a new location. But since the pumps were old, and they couldn’t shut down the water supply to move them anyway, new pumps were needed. Essen used this opportunity to push for dual drive pumps that could keep operating when electrical power was unavailable. Although they were more expensive than single-drive pumps, he was able to make the business case for the purchase.

“All it has to do is save the city once and it pays for itself,” he said. “It avoids a lot of bad PR if you can keep pressure up during an emergency.”

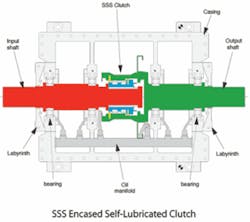

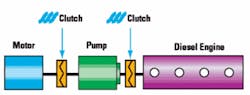

The city purchased two high service pumps from Flowserve Corporation - one a 15 million gpd and the other a 25 million gpd pump. Attached to one side is a motor supplied by Flowserve and on the other is a Caterpillar diesel engine for emergency backup. On each side of the pump, between the pump and either the motor or engine, is a clutch from the SSS Clutch Co. of New Castle, DE. The SSS clutches automatically engage or disengage depending on the relative speed of the pump and the engine or motor, allowing for a seamless changeover.

Under normal operating conditions, the pumps run off their motors, powered by the grid or the onsite emergency generator. When there is a need to use the diesel backup, the operator in the control room fires up the Caterpillar.

“The operator can select diesel or electric through the interface there, rather than having to run down to the pump room like in the old days,” Essen said. “When the RPMs pick up, the clutches take care of making the connection to the pump. It’s a pretty user friendly set up.”

Failsafe

The new pumps have been in operation for 18 months, and Essen says that the system has worked flawlessly.

“When we have a threatening electrical storm, we will generally run one of them under diesel power to minimize any impact from a power glitch or flash,” he said. “Even if the power just goes off momentarily, a lot of the systems need to be reset. This way we can maintain good water distribution under pressure.”

Using the dual drive set up did add to the cost, but Essen said it was worth it. While it hasn’t occurred since installing the new pumps, he has seen enough instances in the past where the pumps lost power despite there being a backup generator on site.

“Its a bad feeling when you are sitting here at the plant with 15 million gallons on site, but the city is running out of water since you have no way to pump it out of here, ” Essen said. “This set up gives us some breathing room to solve other problems - a failed generator system or a cable situation - in a timely manner.”