Multi-Stage Filtration Safeguards Membranes

By Jim Lauria

Membrane filtration systems are the fastest-growing segment of the water purification market, whether for reverse osmosis (RO), nanofiltration, ultrafiltration, electrodialysis reversal or membrane bioreactors. According to the American Membrane Technology Association (AMTA), membranes represented a $9 billion market in 2008. Sales of membrane systems will continue to grow as demand increases for ultra-pure water for drinking, beverage and industrial applications.

Desalination accounted for $2 billion of the $9 billion in membrane sales in 2008, according to AMTA. Desal plants offer an informative look into the economics of membranes, and may shed light on how cost-effective systems may help membrane technologies work more efficiently.

According to The World’s Water 2006-2007, which drew upon data from the U.S. Bureau of Reclamation and SNL 2003, membrane replacement accounts for 5 percent of the cost of operating a desalination plant, labor represents 4 percent, and consumables (such as filter cartridges, media, coagulants, etc.) use 3 percent. Clearly, protecting membranes from contamination and reducing cleaning cycles can dramatically cut operating and capital costs.

The traditional approach to protecting membranes is installing a sand media filter or a cartridge filter upstream of the membrane. But engineers are increasingly seeing the benefits of using a variety of technologies to address pre-filtration needs.

System Selection

The first step in developing a multi-stage filtration system is to look both upstream and downstream. Filtration is a prescriptive process – there’s no sense prescribing a cure if you haven’t examined the symptoms or assessed the patient’s overall health.

Foulants can range widely. Sand, grit, fibrous materials (a particular challenge in membrane bioreactors), biological organisms ranging from algae to bacteria to mollusk larvae, scales and precipitates, oxidants such as chlorine, and gases such as hydrogen sulfide or volatile organic carbons (VOCs) can threaten membranes, but not all are present in every situation. It is vital to understand the source of the water – direct intake from the sea, a buried intake that uses sand or sediment as a natural pre-filter, a river, well or reservoir – and to carefully analyze its contents.

It is also important to consider not only the current condition of the water, but also how environmental conditions could affect it – for instance, the possibility of algal blooms in summer or high turbidity in winter or spring – as well as the possible impacts on the water source from changes in land use in its watershed. Erosion, nutrient enrichment, microbial contamination and algae can all be dramatically affected by land use changes.

In the case of each foulant in the sample, optimum technologies exist for filtering or separating it, based on its size and characteristics (such as shape, deformability or solubility). Including the appropriate technology in a multi-stage filtration system may require a capital investment, but can quickly pay for itself through reduced O&M costs. However, it is also important to consider the downsides that each technology can present.

For instance, at a coal-fired utility plant in the southwestern U.S., managers had sidelined a sand media pre-filter because of persistent problems with media carryover plugging the 1-micron cartridges upstream of the plant’s RO demineralizer unit. Maintenance staff had to change the cartridges every two weeks. Replacing the media filter with an automatic self-cleaning screen filter – which automatically removes filter cake through focused back flushing nozzles when a pressure differential is reached between the inlet and outlet sides of the screen – reduced total suspended solids (TSS) from 10.46 ppm to 0.0001 ppm, protecting the cartridges and membranes while also minimizing maintenance and reducing back-flush water volume by as much as 75 percent.

Of course, no technology is perfect. Even the best woven screen filters do not address soluble contaminants or many particles below 10 microns in size. Wedge-wire screens may let deformable or flat particles through, though the particles may be larger than the nominal filter size. Settling tanks are simple but slow, and they require the use of flocculants and time-intensive clean-outs. Flocculants and other cleaners may react with other foulants in the water and create precipitates or scale in the membranes.

Because one technology is rarely ideal for every situation in a complex system, several may need to be arranged in series to achieve the desired results, capturing a wide variety of foulants identified in inlet samples.

Multi-stage savings

Properly designed, the value of a multi-stage filtration system can be greater than the sum of its parts. Protecting membranes is paramount. But reducing operating costs substantially is quite possible. So is simultaneously improving the environmental footprint of the operation – reductions in chemical use, spent filter cartridges, back-flush water, and energy have ecological significance. In turn, those environmental benefits may have social or political benefits.

About the Author:

Jim Lauria is Vice President of Sales & Marketing for Amiad Filtration Systems, a manufacturer of water filtration systems for agricultural, industrial and municipal applications. He has over 25 years of experience in liquid/solid separation processes, water treatment and resource optimization. Prior to joining Amiad, Lauria owned Team Chemistry LLC, a consultancy that focused on developing new business opportunities for clients’ water treatment technologies. He holds a Bachelor of Chemical Engineering degree from Manhattan College.

Self-Cleaning Filters Play Role in Multi-Stage Systems

Self-cleaning screen and thread filters from Amiad Filtration Systems are being used in multi-stage filtration systems around the world.

For example, a Virginia seawater desalination plant uses automatic self-cleaning screen filters from Amiad for 25-micron filtration before its RO membranes. Two of the company’s six-inch ABF filters readily handle the 600-gpm load. Around the world at China’s Wangtan Power Plant, three 150-micron self-cleaning screen filters are used to remove algae from feed water. As a result, Wangtan maintenance teams don’t have to use coagulants or chemicals to maintain their ultrafiltration/microfiltration membranes.

Self-cleaning screen filters can be specified for even smaller projects. Since 2002, at an isolated ranch in California – whose remote location makes minimizing maintenance and parts replacement a must – a self-cleaning screen filter has provided filtration down to 50 microns for the RO unit that supplies the operation’s drinking water.

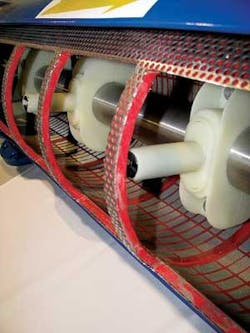

In addition to screen filters, Amiad offers automatic self-cleaning thread filters, called the Automatic Microfiber Filtration (AMF) system. It can provide protection down to the 2-micron level.

Filter assemblies consist of extremely fine fibers wound around spools, and are capable of capturing minerals or even deformable biological particles such as Giardia or Cryptosporidium cysts. When a target pressure differential is achieved inside the filter unit, a focused, high-pressure stream of water passes through the fibers and bounces off of a specially designed plastic deflector, removing the contaminants without interrupting the integrity of the filtration system or requiring cartridge replacement.

The AMF filters are helping protect RO membranes at a seawater desalination plant in Cyprus. A beach well uses the natural sand as a huge media filter. The saltwater then passes through five AMF filters for filtration down to the 3-micron level before entering a cartridge filter that serves as the final polish before the RO membrane vessels. Protecting the cartridge filter with a very high degree of filtration puts most of the polishing burden on the automatic self-cleaning units – dramatically reducing cartridge consumption and maintenance costs for the entire system.