Achieving Reuse Quality Water Using Multiple-Barrier Treatment

By Manuel de los Santos and Terry Reid

As clean water supplies become more limited, the demand for reuse water will continue to grow. Regardless of the treatment system used, the success of any reuse program relies on the biological treatment and the solid/liquid separation. The incorporation of nitrogen and phosphorus removal to the treatment scheme broadens the opportunities where reclaimed water can be acceptable.

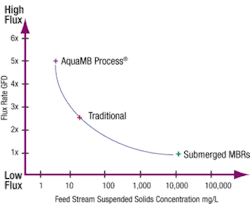

While Membrane Bioreactors (MBR) are growing in acceptance, this technology puts the membranes in the direct application of mixed liquor suspended solids (MLSS), where solids concentrations of 8-10 g/l are a common practice. While the MBR process can offer advantages with respect to space requirements, the elevated solids concentrations demands a higher energy input.

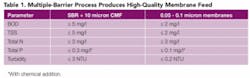

An innovative alternative features a multi-barrier (MB) approach which incorporates progressive staged filtration. Aqua-Aerobic Systems Inc. introduced this technology to its line of products with the AquaMB Process®. This treatment scheme integrates a sequencing batch reactor (SBR) process and cloth media filtration (CMF) to produce a high quality membrane feed with solids less than 5 mg/l.

The improved quality of the water applied to the membranes helps maintain membrane performance while exhibiting lower energy levels.

The progressively staged treatment approach also allows the membranes to operate at elevated permeability, reducing the membrane area required. Depending on the membrane type selected (submerged or pressure), the membrane area required to process a given flow is as little as 20% of that required with a membrane bioreactor.

The multiple-barrier approach can also provide multiple levels of treatment, allowing the operator to discharge effluent directly from the SBR, the cloth media filtration stage, or from the membranes.

Many of the discharge permits in place for municipal wastewater systems are seasonal, requiring different quality parameters based upon summer or winter months. With the MB concept, the operator can elect to operate the membranes on an “as needed” basis. For example, if certain months of the year do not require the quality attainable with membranes, the operator can send a minimal flow to the membranes, or condition them for storage. In applications with extremely stringent objectives, the addition of Reverse Osmosis (RO) may have to be considered. In such situations, the MB process offers ideal water conditioning for the RO system.

Due to the low solids concentration in the membrane feed, recirculation rates are reduced, providing another reduction in the power costs. Where an MBR system may require return activated sludge (RAS) pumps at 400-800% of the average design flow, the low solids level fed to the MB system reduces this recirculation pump sizing to approximately 5-10% of the average flow rate.

The screening of fine particles is a critical element to the longevity and O&M attributed to MBR systems. Since a mixture of the influent waste constituents and MLSS is directly applied to the membranes in an MBR system, fine screening to levels as low as 0.5 to 3 mm is common. Conversely, the SBR portion of the Multiple Barrier process incorporates final sedimentation prior to further filtration. As such, the AquaMB Process requires no special pre-treatment requirements (i.e. fine screens) as grit, hair, wrappers and other debris are removed prior to membrane filtration.

Many membranes are selected to meet future requirements, and the ability to achieve sub-micron particle separation is not an initial objective. With the MB concept, the membranes can be designed into the process flow train but don’t necessarily have to be purchased in the initial plant construction if the current permit does not require membrane quality effluent.

In addition to the flexibility of operation described above, the reduced membrane area and the low solids concentration in the membrane tank can result in reduced capital and O&M costs. As membranes typically represent among the highest capital expenditures in new plant construction, advanced treatment prior to the membranes can reduce the quantity of membranes and minimize the cost of ownership. Additionally, the equipment and chemicals needed to clean the membranes also will be reduced, further reducing O&M costs.

Case Study

One of Aqua-Aerobic Systems’ multiple-barrier processes can be found in the Australian island of Tasmania. The St. Helens Wastewater Treatment Plant was originally designed as a lagoon system. Recently, the Environmental Protection Authority of Australia imposed more stringent effluent requirements and the plant was forced to meet a BOD of 2 mg/l, TSS of 2 mg/l, Total Nitrogen of 5 mg/l and Total Phosphorus of 0.1 mg/l.

In order to meet these new BNR requirements, the engineer and owner evaluated nine different membrane technologies, all but one were MBR processes. After thoughtful consideration of installed costs, operation and maintenance, operability and flexibility, the decision was made to upgrade to the AquaMB Process®. Recently commissioned, this facility includes a dual basin AquaSBR® system with retrievable fine bubble diffusers followed by a 2-disk AquaDisk® cloth media filter with the effluent filtered through pressure membranes. The system is sized for 0.4 mgd average and 0.8 mgd peak flow and designed with the flexibility to operate in single basin mode during low influent periods. The treated effluent is discharged into nearby St. George Bay, which is used for sensitive aquaculture.

About the Authors:

Manuel de los Santos is Senior Applications Engineer, Biological Processes & Membranes, at Aqua-Aerobic Systems Inc. He possesses an M.S. degree in Sanitary and Environmental Engineering from the Universidad de Cantabria, Spain. He has five years of application engineering experience in the wastewater treatment industry with skills in design, application and technical support for biological processes and membranes. Terence K. Reid, P.E., is Product Manager, Biological Processes & Membranes. He has over 16 years experience in the wastewater field with responsibilities that include process and applications engineering, mechanical design and operator training. He has authored articles in the areas of batch reactor, nutrient removal and membrane technologies.