Analysis of MBR and Tertiary Membrane Filtration for Water Reuse

By Dr. Paul M. Gallagher

As municipalities seek new water sources to augment fresh water supplies, water reuse and reclamation are gaining in popularity. Reuse is an economic and environmentally sound solution that uses less energy and reduces overall waste compared to the alternative solution, seawater desalination.

Low-pressure membrane based processes for water reuse have been proven to meet stringent standards. Their advantages include: a physical barrier to biosolids, pathogens, bacteria and nutrients; the flexibility to handle changing wastewater characteristics and plant capacities; fully automated and simple operation; a significant reduction in footprint and operating costs, delivering the lowest cost per volume treated. Low-pressure membranes are commonly used for post-secondary clarification processes for tertiary filtration, and after biological processes such as membrane bioreactors (MBRs).

In conventional activated sludge treatment with tertiary membrane filtration (CAS-MF), the conventional biological process typically includes primary treatment, activated sludge processes and clarification. For water reuse purposes, low-pressure membranes can be used after the clarification step, reducing the size and operating costs of the reuse system. These membranes can be either pressurized or submerged, and both have their advantages, depending on the specific water quality and site requirements. Low-pressure membranes achieve a 4-log or greater reduction of pathogens and suspended solids, and a silt density index (SDI) of 2–3, making CAS-MF technology the preferred pretreatment for RO.

MBRs combine membrane filtration with a conventional biological process. The membrane replaces the secondary clarification, sometimes reducing the plant’s overall footprint as well as capital and operating costs. This system can maintain very high biomass/solids concentrations in the bioreactor (5,000–15,000 mg/L), and this allows the volume requirement of the biological system to be reduced. Fine screening is required in front of the membrane module to protect the membrane. Besides delivering a very high effluent quality suitable for reuse applications, MBR reduces biosolids production and eliminates sludge settle-ability problems.

Comparing CAS-MF and MBR: Two Case Studies

Gerringong Gerroa Sewage Treatment Plant (GGSTP):

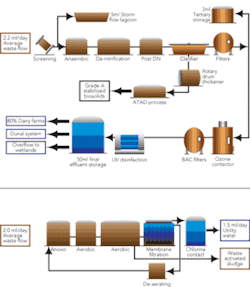

The GGSTP in Australia is a CAS-MF plant commissioned in 2002. Designed to serve a population of 11,000 with an average dry weather flow of 2.2 MLD, the plant consists of coarse screening, biological processes, secondary clarification, sand filtration, ozonation and biological activated carbon filtration. The polishing step for non-potable reuse is achieved with a Memcor® microfiltration system and ultraviolet (UV) disinfection. Waste activated sludge is thickened and digested, and stabilized biosolids are stored on site as liquid before use in agriculture.

North Head Sewage Treatment Plant (NHSTP):

The NHSTP is one of Sydney, Australia’s major outfall sewage treatment plants that treats average dry weather flows of 79 mgd and wet weather flows of up to 370 mgd. This 0.53-mgd MBR plant was constructed to provide water for cooling loops, chemical batching, operation of wet chemical odor scrubbers and process wash down, formerly taken from the Sydney potable water supply.

The system’s process steps are as follows:

- Screened settled sewage (SSS) from NHSTP enters and anoxic zone.

- Mixed liquor return (MLR) enters the anoxic zone at four times the SSS rate. The initial portion of the anoxic zone allows partial de-aeration of the mixed liquor, prior to the mixing point with SSS.

- The combined SSS and MLR flows are mixed under anoxic conditions. Appropriate residence times are allowed for partial denitrification of the MLR.

- Mixed liquor from the anoxic zone enters the aerobic zone and then the MLR pump after an appropriate residence time.

- MLR pumps deliver mixed liquor to the membrane modules, which are composed of hollow fibers. At the same time, membrane agitation air is blown in, creating turbulent two-phase flow around the membranes.

- Filtrate pumps draw clear filtrate through the membranes by applying suction.

- The rest of the MLR is returned to the anoxic zone, as described in the second step above.

The membrane filtrate is disinfected with hypochlorite for 30 minutes before delivery to the on-site industrial water reservoir. Waste activated sludge (WAS) is withdrawn from the aerobic zone and discharged to NHSTP’s headworks, undergoing primary sedimentation and biosolids handling. This WAS quantity is insignificant compared to NHSTP’s primary sludge.

Different Design Approaches

Both the GGSTP membrane system and the NHSTP MBR have had stable operation since startup. The two plants deliver high water quality, with a final biochemical oxygen demand (BOD) between 2 and 2.5 mg/L, respectively. Both plants have achieved nutrient, solids and pathogen removal that is higher than the standard.

The two plants are examples of very different design approaches using low-pressure membranes. NHSTP’s effluent complies with guidelines for reclaimed water use – i.e., urban (non-potable) with unrestricted public access, which is stringent for pathogens but contains no guidelines for nutrients removal. The GGSTP’s effluent complies with the Department of Environment and Conservation, which is stringent for both pathogens and nutrient removal, thus requiring multiple barriers and tertiary treatment with several advanced treatment processes.

NHSTP’s MBR was retrofitted into an existing sewage treatment plant with upstream and downstream processes in place and existing operation and maintenance structures. As the system had to be located on the land that housed the existing sewage treatment plant, space for the MBR was limited. In contrast, GGSTP’s membrane system was newly built as part of the sewage plant. In addition, NHSTP’s MBR was designed to treat a constant flow without the need to handle peak flows, whereas GGSTP’s system was designed to handle a wide range of flows with a secondary clarifier sized according to the hydraulic loading. Thus, the two plants’ footprints vary widely.

Fouling Potential

Since membrane filtration and MBR are used as pretreatment steps for high-pressure membranes (nanofiltration/reverse osmosis) used for potable reuse of high quality industrial process water, membrane fouling is the main technical challenge. The SDI is a general indicator of the fouling potential of water produced by these two treatment processes. SDI data was collected from several installations of tertiary membrane filters and MBR. The site characteristics are summarized in Table 1 and indicate that a range of municipal waste, industrial waste, full-scale and pilot-scale sites were included.

The data indicated that all the sites produced filtration with an SDI generally below 3.0, which is the preferred level for membrane-filtered RO feed. In most cases, the SDI ranges from 0.5 to 2.0. The SDI data showed that there does not seem to be a systematic difference between tertiary membrane filtration and MBR as RO pretreatment. Furthermore, SDI seemed to be insensitive to moderate breaches of membrane integrity. The primary determinant of SDI appeared to be the upstream biological treatment process, with higher SDI values generally corresponding to upset conditions in the bioreactor. Thus, the conclusion is that both tertiary membranes and MBR are likely to provide comparable and highly satisfactory RO pretreatment with the process selection being based on process economics, customer preference and site-specific conditions.

About the Author:

Dr. Paul M. Gallagher is Director of Global Process Technology for Siemens Water Technologies. He can be reached at [email protected].