Evolution of Sequencing Batch Reactor-Membrane Bioreactor Technology

By Lloyd W. Johnson

Aqua-Aerobic Systems (AAS), in partnership the Colorado School of Mines (CSM), has completed the successful startup of a sequencing batch reactor-membrane bioreactor (SBR-MBR). The package system treats domestic wastewater generated by a 400-apartment, student and faculty housing-complex located on the CSM campus in Golden, CO. This success is rooted in a 15-year development program that follows an informal Stage-Gate® process.

Depending on the level of formality of a company's development process, each successive stage requires a review before a “go” or “no-go” decision is made. The time necessary for product development in the water industry tends to be rather long. A primary reason is an historical aversion to new equipment and process concepts due to the significant financial investment required by end-users to incorporate them into existing systems.

It is also a function of the potential risks associated with adverse environmental impacts and unfavorable public opinion should the new technologies not perform as designed. To be successful in the water industry, patience, willingness to invest significant company assets, and nurturing collaborative partnerships are essential. The development and implementation of this package SBR-MBR treatment system in Colorado reflect such efforts.

Sequencing batch reactors (SBR) are a common, although not a predominant, technology for treatment of municipal and industrial wastewater. Bench-scale SBR systems are often employed in laboratory studies to define kinetic parameters and to determine the overall treatability of various streams. Over the past 25 years, AAS has designed, manufactured, and sold over 1000 commercial-scale SBR systems. The existing installation base and market drivers such as high quality effluent, on-site water reuse, and space limitations in prime real estate areas have all provided the development initiatives for the SBR-MBR concept.

The first SBR-MBR prototype system developed by AAS was designed to treat 1400 gallons of influent per day, and was installed at a small municipal wastewater treatment plant in Rockton, IL. The resulting on-site study lasted 18 months and required the attention of one full-time researcher/operator.

During the study, the SBR process tank was close-coupled with an external pressure-fed membrane that was provided by Pall Corp. Due to the basic membrane design and its application in wastewater treatment, a screening step was required between the bioreactor and the membrane unit. Screening influent waste streams to a high degree was generally deemed unnecessary by the industry at that time; however experience in Rockton revealed that this was not the case. Today, effective influent pre-screening is considered necessary and is typical of MBR designs and operation.

Although the process worked well and the membrane produced the desired water quality, researchers were unable to substantially distinguish this technology combination from existing flow-through MBR systems in terms of higher flux capability and lower operational costs. A “no-go” decision was therefore made and the SBR-MBR development project was temporarily suspended, but on-going technology reviews continued through various avenues that included market investigations, plant visits, and collaborations with business partners that had been developed throughout the prototype study.

As noted, collaborative partnerships are key elements to success, and it was one such partnership that revitalized the SBR-MBR project. When Koch Membrane Systems (KMS) contacted AAS and provided access to Koch-PURON™ technology, AAS staff realized that they were in a position to combine two unique technologies that offered a combined technical and competitive solution to address existing market needs. A second prototype system was then designed, and a subsequent study was initiated. The program was further enhanced by a perceived market driver for decentralized package treatment systems in water reuse applications.

In addition to other resources and services, the WateReuse Association (WRA) and the Water Environment Federation (WEF) provide excellent networking opportunities. It was through membership in these professional organizations that AAS met CSM professors Drs. Jorg Drewes and Tzahi Cath. Both CSM and AAS expressed mutual interest in, and recognized the potential long-term benefits of, a collaborative study with CSM Advanced Water Technology Center (AQWATEC) and Mines' Small Flows Program. A study plan was developed and approved, and the Golden, CO, test site was identified.

During the design phase of the SBR-MBR development, AAS worked closely with CSM to prepare the site. This included adding a by-pass connection to the sewer line, installing an in-ground receiving/pre-settling tank, and providing utility connections. This level of site preparation is not normally required since test locations are often at existing wastewater treatment facilities. The package prototype treatment plant was shipped to Golden in September 2008, and after four months of operational checks and running on clean water, it was seeded with activated sludge collected from a local SBR plant.

Initial goals for the study are to maintain continuous stable unit operation and to establish a baseline system performance by monitoring such parameters as influent and effluent organics, nitrogen, phosphorus, and turbidity values. Reactor mixed liquor suspended solids (MLSS) and mixed liquor volatile suspended solids (MLVSS) values, transmembrane pressure (TMP), chemical cleaning requirements, and flux stability are also being evaluated.

The current SBR-MBR plant is equipped with a full complement of instrumentation coupled with a SCADA system for on-line monitoring and control. Each reactor has TSS, DO, and level probes as well as a vacant slot for an additional probe. Each membrane tank is equipped with a level probe, and the common MLSS return trough boasts pH, TSS, and DO/temperature probes in addition to an unoccupied slot for a future probe if required. Pneumatically actuated valves control both the liquid and air flow in the system. The influent feed, MLSS membrane feed, and membrane permeate pumps are all VFD-controlled.

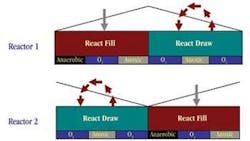

Basin 1 receives flow for one hour while Basin 2 discharges. Each basin is equipped with a set of timers to create the desired aerated and non-aerated events. Hydraulic mixing is provided by a submerged pump fitted with two directional nozzles. An inherent advantage of the time-based SBR operation is the ability to relax the membranes for permeate withdrawal if the influent flow is less than design. In addition, the SBR basin can be sized to provide some equalization for flow events in excess of design average; the membrane flux rate is automatically adjusted for permeate peak flow if the influent flow is higher than the design average.

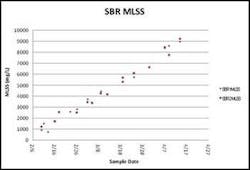

The plant was seeded with SBR activated sludge on February 9, 2009, and the initial MLSS concentration in each basin was approximately 1000 mg/l. The system achieved a steady-state 8000 mg/l design MLSS concentration on April 1, 2009. Figure 4 illustrates the steady increase in system MLSS values from early February through mid April.

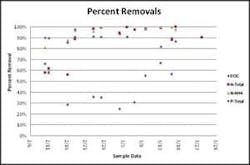

Immediate elimination of carbonaceous and nitrogenous components was achieved and removals exceeding 80% occurred within the first 12 days. By March 13, carbon removal measured as DOC approached 90% with a typical permeate concentration of 7.2 mg/l. Similarly, total nitrogen removals reached 95% with permeate concentrations ranging from 3 to 0.2 mg/l. Ammonia removal was nearly complete. Biological phosphorus removal started very slowly in the range of 30 to 50 % and progressed to 90% as the system reached steady state operation. Total phosphorus permeate concentrations have approached values of 0.4 mg/l. Research staff anticipate similar removal efficiencies in the future now that the system has reached a steady-state condition.

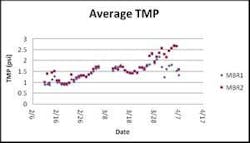

Each membrane tank is fitted with one 30 m2 hollow-fiber membrane module. The membrane is of a single header design, consisting of a self-supporting mounting frame, side baffles and permeate and air scour headers. At this point in the study, two maintenance cleaning events have been performed, one at the end of March and the second in early April. MBR 1 membrane recovery occurred during both events while MBR 2's membrane responded to the second. Nearly full recovery of both was achieved.

The CSM test site provides the necessary real life conditions for decentralized treatment. The system has reached a steady state condition; however, it will soon be challenged with the campus' summer break. During the break, researchers expect that the flow and load to the system will decrease substantially; this will require operational adjustments to maintain a healthy system. With the two basin SBR configuration, researchers have the flexibility to consider a smaller batch volume or practice single tank operation for extended low flow and lower loading events. Based on the success of the present operation, coupled with confidence in the flexible design features, AAS has proceeded with commercializing of the SBR-MBR product.

Future testing will include constituent profiling of the biological process with time, adjusting process settings to find operating limits, evaluating the process for removal of micro-constituents, and evaluating different operating strategies to improve membrane performance and longevity. --m

About the Author:

Lloyd W. Johnson, P.E., is vice president of Research & Development at Aqua-Aerobic Systems. Johnson holds a BS in Civil Engineering degree from the University of Hawaii and MS Product Development degree from Northwestern University. He has had experience in the wastewater treatment industry since 1975 related to process engineering and equipment manufacturing. He may be contacted via e-mail at [email protected].