Products & Technology

Batch reactor

The AquaExcel® batch reactor incorporates benefits of the AquaSBR® system with advanced decanting and process monitoring and control. It features the AquaEnsure® decanter and IntelliPro® process management control system, offering integrated comparative analysis and proactive operator guidance via the BioAlert™ optimization program. The AquaExcel® system is suited for enhanced nutrient removal, nitrification, phosphorus removal, reuse quality wastewater and industrial pre-treatment applications.

Aqua-Aerobics

Tel: 815-639-4456

Web: www.aqua-aerobic.com

RO treatment system

N.A. Water Systems, a Veolia Water Solutions & Technologies (VWS) company, has received a patent for its AMDRO™ technology, a reverse osmosis (RO) process for treatment of acidic wastewater. This process is particularly applicable to the mining and fertilizer production industries. The patented process includes VWS’ proprietary ACTIFLO® clarification technology and media filtration for pretreatment, followed by a doublepass RO and ion exchange polishing to produce a treated water stream suitable for discharge and reuse. The key to the technology is the operation of the pretreatment and the first-pass reverse osmosis process under acidic conditions to inhibit the precipitation of scaleforming compounds.

N.A. Water Systems

Pittsburgh, PA

Tel : 412-809-6712

Web: www.nawatersystems.com

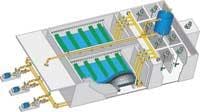

Packaged MBR systems

Koch Membrane Systems has announced the North American introduction of its packaged membrane bioreactor (MBR) systems. Featuring Puron™ submerged membrane modules, the pre-engineered systems produce high-quality effluent while significantly reducing the treatment system footprint, installation cost, and manpower commitment for small wastewater treatment plants. Using submerged membrane technology, the packaged MBR systems integrate membrane filtration and bioreactor processes into a turnkey solution for new and retrofit wastewater treatment plants. Sized for systems that require a capacity of up to 200,000 gallons per day, the packaged systems are ideal for denitrification, advanced tertiary polishing, and scalping applications. The systems produce effluent that is capable of meeting stringent requirements for water reuse and recycle.

Koch Membrane Systems Inc.

Wilmington, MA

Tel: 888-677-5624

Web: www.kochmembrane.com

Fine screens

The Spiralift SL fine screens, washes, transports and compacts channel-borne wastewater solids while leaving essential organics in the flow. This system is easy to install in existing channels, can reduce solids disposal costs and protects downstream equipment. The fully integrated system includes a Taskmaster® grinder, a shaftless screw screen, and control system which coordinates the system’s normal and special functions. The PLC based control system uses flow level data to cycle the screw to minimize power and wear. The units are provided standard with stainless steel screens and screw housings. The can be supplied with a choice of electric or hydraulic drives and a variety of channel widths, flow and lift requirements.

Franklin Miller Inc.

Livingston, NJ

Tel: 800-932-0599

Web: www.franklinmiller.com

Water Reuse

Siemens offers a variety of water reuse and recycling systems including wastewater treatment technologies ranging from physical, chemical and biological treatment to membrane filtration. Its brands include Memcor® membrane filtration and Trident® clarifiers. Another popular filtration technology in its portfolio is the Forty-X™ Disc Filter. To ensure effluent quality, these technologies can be combined with the company’s UV disinfection for a multi-barrier approach.

Siemens Water Technologies

Waukesha, WI

Tel: 800-525-0658

Web: www.water.siemens.com

Membrane bioreactor

WesTech offers the ClearLogic™ Membrane Bioreactor (MBR) featuring the new Alfa Laval Hollow Sheet™ Membrane Technology. Advantages of the new MBR system include Ultralow Transmembrane Pressure and even flux over the entirety of the flat plate membranes. The system offers simple operation; lower TMP means fewer components, decreased maintenance, and fewer cleaning cycles. Ultrasonically welded membranes allow for full backflush capabilities. The company offers complete MBR systems, from turn-key plants to existing plant retrofits.

WesTech Engineering Inc

Salt Lake City, UT

Tel: 801-265-1000

Web: www.westech-inc.com

MBR systems

Pall Aria MBR systems use the same hollow-fiber membranes as the company’s water treatment systems in a new submersible design. The result is a reliable membrane bioreactor at a remarkably low cost. By combining aerobic biological treatment with an immersed membrane system, the MBR system significantly reduces the footprint of a wastewater treatment plant while improving effluent quality. Customized systems are available. From fine screens to UV disinfection, Pall can supply the complete scope of technologies required to meet specific wastewater treatment needs.

Pall Corp.

East Hills, NY

Tel: 888-428-5597

Web: www.pall.com

Desalination pre-treatment

ITT’s Water & Wastewater group offers two desalination pretreatment system technologies—the Leopold® Clari-DAF® dissolved air flotation system and Leopold FilterWorx® rapid gravity media filtration. They can be used individually or in combination to provide influent to feed RO membrane filters. The Clari-DAF system requires no polymer, has high loading rates, is compact in design and effectively operates in low temperature raw water. It features a rapid start-up with good quality effluent achievable within 45 minutes. The FilterWorx rapid gravity media filter system has a downflow design, efficiently stores solids, handles wide swings in solids loading, and provides long filter runs with high production rates. It is also versatile in meeting a variety of source water conditions and can be designed to a variety of site conditions or existing filter basins.

ITT Water & Wastewater

Zelienople, PA

Tel: 724-452-6300

On-site treatment

Bio-Microbics has introduced a new generation of wastewater treatment solutions for onsite and decentralized treatment. Its BioBarrier® Membrane Bioreactor (MBR) helps meet the increasingly stringent needs of environmentally sensitive areas. The preengineered, modular system uses flat-sheet membranes and is completely automated using advanced control strategies. It ships ready to install in new and existing tank configurations. The membranes and processes used in the system act as an impenetrable physical barrier for nearly all common pollutants found in wastewater.

Bio-Microbics Inc.

Shawnee, KS

Tel: 800-753- 3278

Web: www.biomicrobics.com

Suspended solids meter

Easily measure the concentration of sludge’s or slurries without the reading being affected by color using the Markland Model 502 Suspended Solids Meter. The meter can be used in drinking water plants to measure the concentration of the backwash sludge from sand or membrane filters before it is sent for further processing. In wastewater treatment plants it is used to measure primary, secondary and return activated sludges. The syst e m uses the attenuation of ultrasound to read the concentration. The meter can be mounted in open-top tanks or pipelines.

Markland Specialty Engineering

Toronto, Ontario

Tel: 905-873-7791

Web: www.sludgecontrols.com

EDI, membrane system

With Septron Bio-Safe, Christ now offers the world’s first electro-deionization module with an integrated membrane stage. It is based on the proven and patented spiral-wound technology and has an additional membrane stage for removal of particles and bacteria. The EDI module is available in a cold-water version and a version which can be sanitized with hot water. Both versions are available in various sizes with outputs of 500 to 3,000 l/h. The combination of this module with a preceding reverse osmosis stage makes it possible – without additional ultrafiltration – to produce Highly Purified Water (HPW) with bacterial counts of = 10 CFU/100 ml. The module can be retrofitted on existing Osmotron systems and permits a considerable improvement in the microbiological safety of existing pure water systems.

Christ Water Technology Group

Web: www.christwater.com

Band Screen

The Headworks Eliminator™ Band Screen protects MBR plants and sensitive biological systems with very fine openings by eliminating carry-over and by-pass. This design forms a continuous band which travels parallel with the channel wall. The water enters through the center of the screen, passes through the stainless steel sieve elements and exits through the sides of the unit. Screenings are captured by the elements and are carried up to the discharge point where they are removed by a Dual-Surge™ spray header system. The material is discharged into a sluice trough and conveyed for collection and disposal, typically to a screenings washing and dewatering system.

Headworks Inc.

Houston, TX

Tel: 713-647-6667

Web: www.headworksusa.com

RO Elements

Toray Membrane USA has introduced two new low pressure brackish models of TMG20-400C and TMG20-430C reverse osmosis membrane elements. The new products feature a new permeate tube design that standardizes permeate tube dimensions without the need for special adaptors when replacing competitor elements. The company also offers new 34 mil brine spacers for models of TM720N-400 high rejection brackish elements and TMG20N-400 low pressure brackish elements. The thicker brine spacer makes the element more resistant to fouling and easier to clean in waters with higher suspended solids and difficult process water applications.

Toray Membrane USA Inc.

Poway, CA

Tel: 858-218-1518

Web: www.toraywater.com

Screening system

Hydro-Dyne’s Hydro-Flo water and wastewater screen is specifically designed to protect sensitive process equipment such as membranes and provides no screen bypass or carry-over. Its Bypass Gate eliminates the need for a separate bypass channel. The screen is made entirely of stainless steel and is available with perforated plates, wire mesh, or laced link grids ranging from 1 mm to 25 mm openings. The screens have no submerged drive parts and have a complete enclosure for safety, aesthetics and odor control.

Hydro-Dyne Engineering Inc.

Oldsmar, FL

Web: www.hydro-dyne.com

MBR system

The Smith & Loveless Titan MBR™ combines efficient pre-engineered system design with S&L Flat-Plate Membranes. Submerged in the aeration section of the tank, the membrane maintains high permeability and flux rates even at peak-day rates. Because the system employs air scouring to prevent fouling, it does not require back-pulsing or the associated equipment and chemical costs typical of other systems. Because of its robust support, Flat-Plate units also experience less wear and tear than hollow-fiber types and can be cleaned in place. The MBR systems come in standard and custom designs, and result in smaller footprints than conventional systems. Custom options can be included based on the desired effluent characteristics. Flow capacities range from 5,000 gpd to 3 mgd.

Smith & Loveless

Lenexa, KS

Tel: 913-888-5201

Web: www.smithandloveless.com