Hair in Membrane Bioreactors, Getting to the “Root” of the Problem

by Matt Schowengerdt

In recent years the use of membrane bioreactors (MBRs) for the treatment of municipal wastewater has increased significantly. MBRs use ultrafiltration membranes to provide a clarification barrier between the mixed liquor solids and reactor effluent. As operating experience increases, issues have surfaced with hair accumulation decreasing MBR system performance. As a result, many existing MBRs are undergoing extensive maintenance to clean the membranes or in the worst case, possibly requiring complete membrane replacement.

To combat this problem, most MBRs require some sort of fine screening prior to treatment in the reactor. Most fine screens available on the market today have an effective opening size of 1000-6000 microns, (1 – 6 mm) and some screens can go as low as 500 microns in a series configuration. However, according to the “The Physics Factbook”, typical human hair ranges from 17 to 181 microns, much smaller than the opening found in traditional fine screening. This gap results in significant quantities of hair still entering the MBR.

The Salsnes Filter, developed in Norway in 1992, uses an innovative approach to screening that allows the use of a mesh opening of less than 250 microns. By the nature of its operation, the filter achieves an effective opening of typically 50 to 80 microns.

The Salsnes Filter

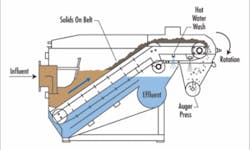

The Salsnes Filter is a rotating belt, primary treatment sieve. As wastewater enters an inlet pipe, it is intercepted by an inclined moving mesh belt. This continuous mesh belt is composed of nylon and Kevlar material that rotates around a drive and tail pulley assembly. The belt has molded-in teeth on each side that are driven by a sprocket type head pulley to insure positive drive and to eliminate the need for routine realignment.

As wastewater passes through the moving mesh belt, solids are deposited and a mat of solids forms. Solids are removed by the mesh screen. Liquid that passes through the filter is collected after the screen cloth and discharged into the outlet pipe. As the mat builds, the effective opening becomes an order of magnitude finer than the openings in the mesh, allowing very high solids removal rates. At the same time, as effective head loss across the belt increases, the system is monitored by the PLC, where an internal algorithm speeds up or slows down the speed of the belt to maximize mat thickness while exposing clean belt to minimize head loss. Once the water is filtered, it is baffled around the return belt to maximize solids removal.

After the matted belt is rotated out of the wastewater, solids deposited on the mesh screen are then transported upward to the sludge compartment, where the belt is cleaned and the solids are thickened and dewatered. The belt cleaning system uses an air knife, blowing air in the opposite direction as the mat was formed, to produce a 4% to 8% solid that is collected in a trough. A take-away screw in the bottom of the trough then takes those solids to a wedge wire extruder screw assembly producing a final solids cake of 24% - 40%.

Five units are modularly sized for a peak flow rates of 0.2, 0.5, 1, 2, or 3.8 million gallons per day (MGD). Typical total suspended solids removal is between 40% and 80%. Due to the ultra fine effective opening in the belt mesh mat, the filter effectively captures hair as part of that TSS removal.

Additional Benefits

Additionally, the Salsnes filter effectively acts as a primary clarifier with a fraction of the footprint and capital cost. The unit will function as a primary clarifier by inherently removing up to 30% of the particulate biochemical oxygen demand (BOD). Soluble BOD is returned to the plant in the filtrate from the wedge wire extruder screw assembly. Removing BOD enables the plant to operate less aeration, use less basins, decrease biosolids digestion, and decrease biosolids disposal, thus saving significantly on capital and operating expenses. Independent engineering reports concluded that a 6' x 8' Salsnes footprint could take the place of a 60' primary clarifier.

Case Study

A demonstration study was performed at a Southern Alabama municipal wastewater treatment plant. The Salsnes unit was operated with a 350 micron and a 250 micron belt.

The first filter trials were performed using a 350 micron mesh belt. Flows ranged from 50 to 200 gpm, and exhibited an influent TSS averaging 345 +/- 77 mg/L. The Salsnes Filter™ achieved an average of 67% removal down to 110 +/- 25 mg/L TSS. Composite samples were collected periodically during operation days over a varied range of flow rates. The composite sample analyses revealed a 55% reduction in TSS, 35% reduction in BOD5, 18% reduction in FOG, and a negligible 4% reduction in soluble ammonia nitrogen. Cake produced during operations with the 350 um belt averaged 31% total solids.

During the second week of operations, the Salsnes Filter™ was run with a 250 micron mesh belt installed to determine whether a finer mesh belt would enhance results obtained previously in operations. Flows ranged from 50 to 180 gpm, with influent TSS averaging 330 +/- 51 mg/L. The Salsnes Filter™ achieved an average of 72% removal down to 90 +/- 21 mg/L TSS. Composite samples collected reflect periodic sampling throughout operation days over a varied range of flow rates. The composite sample analyses revealed a 45% reduction in TSS, 30% reduction in BOD5, 24% reduction in FOG, and a negligible 4% reduction in soluble ammonia nitrogen.

The data showed that the particle size distribution favored at 350 micron belt for full scale operation and while not quantified, a considerable amount of hair was visible in the dewatered cake.

Conclusion

Because of the very small effective opening produced through the formation of a solids mat, Salsnes Filter is a superior technology for MBR prescreening. It is particularly effective for the removal of hair from the influent, a growing operational issue with MBR systems. Additionally, the filter will remove particulate BOD, reducing the capital and operating costs for MBR systems. The Salsnes Filter also features a small footprint, matching the space-conservative advantage of MBR systems. —m

About the Author:

Matt Schowengerdt, P.E., is the Director of Sales for Blue Water Technologies. He has 22 years of experience in the wastewater treatment industry. He can be reached via email at [email protected].