Operating Experience with Rotating Membrane Bioreactors

by Sandra Schuler

Hans Huber AG, based in Berching, Germany, introduced a novel rotating flat sheet membrane bioreactor (MBR) to the wastewater treatment market in 2002. In the years since, the system has been installed in 20 municipal and industrial wastewater treatment plants worldwide.

The company's Vacuum Rotation Membrane (VRM®) technology offers lower energy demand through sequential cleaning, simplified operation, and reduced pretreatment needs. The rotating flat sheet membranes operate with extended chemical cleaning intervals due to the shear forces introduced by the rotational movement. These shear forces together with the high intensity air scour remove any solids build-up on the membranes, which helps reduce membrane fouling potential. Chemical cleaning once or twice a year has shown to be sufficient for all operating VRM plants.

Operational performance has demonstrated the system's ability to meet the world's most stringent regulations, including California's Title 22 water recycling criteria.

Energy consumption for membrane air scouring is a significant operating cost for any membrane bioreactor facility. Huber's rotational design allows for a significant reduction of the amount of scouring air needed to prevent membrane fouling. In addition, the scouring air is introduced at only half the water depth which reduces the air pressure and thus the blower's power consumption. This design has proven to be reliable and has led to considerable savings in operating and maintenance costs.

Case Studies:Low Temperature Project

One of the first MBR plants using the VRM technology was a small plant at the Schwägalp valley railway station in Switzerland. It was designed for 780 residents and an average dry weather flow of 26,500 gallons per day. The treatment plant clarifies the wastewater of an alpine hotel, a cheese factory and a small guesthouse.

The rotating membrane unit (VRM 20) was installed in early 2002. During the summer season the plant has to handle up to 34,500 gallons of wastewater per day. Flows during the winter months can be as low as 1,300 gallons per day. Another challenge is the snow melt in the spring which leads to very low wastewater treatment temperatures.

Despite the enormous variations in flow and temperatures, plant operation is stable and reliable. Effluent is of a consistent high quality and membrane permeability is up to 12 gfd/psi. The plant operates with a membrane flux of 7.6 gfd, making sure that the membranes do not foul during the low temperature period.

The biological treatment stage achieves a COD reduction of nearly 97% and a total elimination of ammonium nitrogen. Maintenance for the MBR plant is minimal and is conducted by the operating staff of the railway company. Manual operator intervention is only necessary for excess sludge removal. The plant has been in operation for more than six years and only twice have the membranes required chemical cleaning. To date there has been no replacement required of any membrane modules due to failure or wear.

Protecting a Drinking Water Source

The new MBR plant for the small Spanish community of Arenas de Iguña, located near the coastal town of Santander, was put into operation in summer 2006. Until recently, the community had no sewage treatment plant at all even though drinking water for the region is taken from the river just a short way downstream from where the town's wastewater is discharged.

As problems with water contamination increased, it was decided in early 2005 to build a wastewater treatment plant with a membrane bioreactor. Huber received the order to supply the equipment for mechanical pretreatment, grit washing, the membrane bioreactor and sludge thickening.

Arenas de Iguña is the first MBR plant to use Huber's VRM 30 unit. The larger unit and higher packing density reduces the footprint of the membrane tanks and leads to further reduction in air scour flow and energy costs as well as lower operating and chemical cleaning costs. The complete MBR plant was built with only four membrane units.

Rendering Plant Wastewater

GZM in Lyss, a subsidiary of Centravo AG, is the largest rendering plant in Switzerland. Wastewater generated in its production process shows a high and varying load of organic nitrogen compounds. Since the fall of 2006, the wastewater has been treated biologically in a membrane filtration plant prior to being discharged into the river Alte Aare.

One incentive to build an onsite MBR facility at the plant was the capacity shortage in the local municipal wastewater treatment plant.

The company's different wastewater flows are collected and remain as a combined flow for one week in a mixing and regulation tank with an agitation unit. Undissolved material is removed by dissolved air flotation (DAF) prior to biological wastewater treatment in the bioreactor. After separation of the activated sludge by the membrane filtration plant the effluent is discharged into the local river. Some of the permeate is reused as service water for cleaning purposes within the plant.

The biological treatment system has an average daily capacity of 130,000 gallons. The system is designed with two lines each consisting of a biological treatment stage with intermittent denitrification and a membrane filtration unit (VRM 20). The MBR plant was commissioned in November 2006. Initially an issue with the DAF pretreatment system required a non-scheduled membrane cleaning, however from that point forward one annual cleaning has been sufficient.

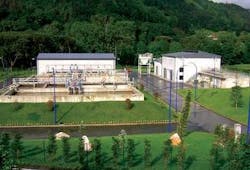

A Fast Solution for a Tourist Resort

MBR plants don't have to be complicated, but can be designed, built and put into operation within a short time period. The 640,000 gallons per day MBR plant for a tourist resort in Los Cabos, Baha California, only took 8 months from preliminary design to final start-up of the membranes.

The effluent produced by the membrane bioreactor is reused for landscape and golf course irrigation.

A rotating drum screen with 3 mm (1/8”) perforated plates at the head of the treatment plant protects the membranes. The screen is installed in a stainless steel tank and combined with a grit and grease removal unit also made of stainless steel (Huber Rotamat® Complete Plant Ro5). The MBR plant only needs two membrane units (VRM 30) saving time on installation and maintenance. The units are installed in separate membrane tanks after the aeration tank.

Currently only one membrane unit is installed for an average flow of 320,000 gpd and a peak flow of 450,000 gpd. The second membrane unit will be installed when the capacity of the plant increases in the future.

About the Author:

Sandra Schuler is an MBR Process Engineer for Hubert Technology. She received her Bachelor Degree in Environmental Engineering from the University of Applied Sciences in Bremen, Germany, and holds a Masters of Science Degree in Water Resources Engineering and Management from the University of Stuttgart, Germany.