Scouting for Clean Water in a Remote Location

Located at 10,400 feet in the Uintah Mountains of Utah, Camp Steiner is the highest Boy Scout camp in the United States. Previously, the Great Salt Lake Council (GSLC) of the Boy Scouts of America used a 3.0 and 0.5 micron bag filter system to treat the water for the scouts that attend the camp each summer. After every 300 to 400 gallons of treatment, fouling would cause the bag filters to blind off. This cost the GSLC $60,000 each summer in bag filter replacements, in addition to the considerable labor required to operate and maintain the system.

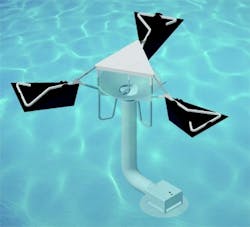

Through an exhaustive study, the AltaPac™ ultrafiltration membrane system was determined to be the preferred option for a replacement system due to its small footprint, low installation cost, high-quality finished water, ease of operation, transportability, and low maintenance and monitoring requirements.

Figure 1: Without an existing building on site, the system remained on the trailer, protected by a tent, for the entire summer.

WesTech Engineering worked directly with the GSLC and provided the ultrafiltration membrane system to Camp Steiner in July 2008. Throughout the summer, the system treated water from both Scout Lake and a nearby spring, with raw water turbidities up to 5 NTU. The raw water first passed through a 200 micron pre-strainer and then through two ultrafiltration membranes with a pore size of 0.01 micron, producing filtered water with an average turbidity of 0.022 NTU.

Figure 2: WesTech modified a short flatbed trailer to provide the extra clearance and heavy-duty load capacity needed for transport to the camp.

The ultrafiltration membrane removed all coliforms that were present in the raw water, and reduced the heterotrophic plate count from 470 CFU/mL to the detection limit of <1 CFU/mL. A submersible transfer pump was used to pump the water from the system’s filtered water tank to the 16,000 gallon storage tank. The system demonstrated a permeate production rate up to 70 gpm, was backwashed every 120 minutes, and did not require a chemical clean throughout the summer.

Because of the remote location, special considerations had to be made for transporting and operating the system at the camp. The unmaintained dirt road that leads to Camp Steiner is full of switchbacks, ruts, and rocks making standard shipping virtually impossible. To accommodate, WesTech modified a short flatbed trailer to provide the extra clearance and heavy-duty load capacity needed for transport to the camp. As there was not an existing building on site, the AltaPac™ remained on the trailer for the summer with a tent for protection from the elements. A 480 volt diesel generator located at Camp Steiner was used to power the system.

WesTech arranged a service and maintenance contract with the GSLC to transport the AltaPac to Camp Steiner at the beginning of each summer and perform start-up and operation services. At the end of the camp season, WesTech transports the unit back to the manufacturing facilities in Salt Lake City, performs a chemical clean and any system maintenance, and stores the unit for the winter season.

About the Company:

Founded in 1972, WesTech Engineering supplies process equipment for water, wastewater and industrial applications. From screening and headworks to tertiary treatment, from petrochemical process to water reclamation and drinking water, WesTech offers standard and custom process solutions for efficient solids-liquid separation.