Ultrafiltration Pretreatment in Seawater Desalination: Cost-Savings and Performance Advantages

By Markus Busch, Robert Chu, and Steve Rosenberg

In the early days of seawater reverse osmosis (SWRO), there was a tremendous need for reliable pretreatment but only trial and error taught appropriate solutions, such as well-optimized coagulation schemes followed by dual-stage, dual-media filtration. Nowadays ultrafiltration technology is also available, but to what extent and how cost effectively can it address SWRO pretreatment needs? And to what extent do market needs and technology capabilities match?

Figure 1: The installed capacity plotted versus the installation year for dual membrane system references for seawater desalination that have been built, are being built, or are planned, based on the authors’ industry knowledge.

To address the latter question, one must look at market needs and trends. Two market needs, in particular, will be examined: minimum primary pretreatment schemes and low environmental impact schemes.

Adoption of Ultrafiltration Technology in SWRO Desalination

In the last ten years, ultrafiltration (UF) or microfiltration (MF) pretreatment has gained widespread attention as potential pretreatment to seawater desalination by SWRO. Systems composed of UF or MF pretreatment for SWRO desalination are often termed “integrated membrane system” or “dual membrane system.”

Between 1995 and 2005, many pilot studies were undertaken. In recent years, a number of SWRO plants — some very large (>100,000 m³/d) — have implemented ultrafiltration or microfiltration pretreatment.

The data on adoption of ultrafiltration for SWRO pretreatment is actually very promising with regard to the speed of adoption: already 42 larger scale seawater desalination plants, with a joint capacity of about 3.4 million m³/d of SWRO desalinated water, are using or are planning to use ultrafiltration as pretreatment. For the 2010-2011 period, the start-up of a multitude of large plants is planned.

Market Needs Driving Adoption

There have been various market needs that have emphasized considering ultrafiltration pretreatment over conventional pretreatment:

- Ability to cope with difficult waters: Some feed waters from the more contaminated seas have posed significant challenges to SWRO systems in the past (e.g., Persian Gulf, Yellow Sea, Gulf of Mexico). Sea bodies with medium quality can pose challenges as well if captured with low sophistication intake systems (e.g., channel, short pipe) because algae blooms at the top surface or suspended solids from the sea ground created during storms will influence the intake quality.

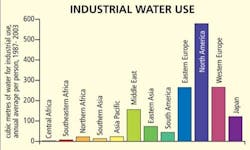

- Reliability: High value is given to reliably reaching maximum plant capacity. This is the case in industrial plants, for example, where the cost of downtime due to lack of water is much larger than the water production cost.

- Plant footprint: UF pretreatment systems generally require a lower footprint than media filtration systems, especially where dual-stage media filters in combination with sedimentation or flotation are used. Site-specific conditions, such as size limitations or buildings with high overhead costs, will increase focus on this aspect.

- Ease of design and operation: Despite requiring more focus on sustained permeability and productivity, ultrafiltration systems provide much more stable water quality than a multimedia filtration system does, without the need to monitor filter ripening time or breakthrough, or the need to ensure appropriate layering of multimedia after backwash. Therefore, process design and control is easier and more automated than with conventional pretreatment, and this enables a wider market group access to reliable SWRO operation, especially participants with less know-how in multimedia filtration, or in smaller plants that do not have the resources to monitor media filters.

- Lower environmental impact: Higher chemical doses and sludge quantities due to the larger required coagulant doses in conventional pretreatment cannot be tolerated for environmental reasons. This trend is apparent in some of the Australian and Californian projects.

- Lower pretreatment stage cost: The general perception is that UF is more expensive than conventional pretreatment. However, a key consideration is the composition of the conventional pretreatment: Is it constituted from single- or dual-staged multimedia filtration? Are coagulation/flocculation chamber designs used? Is a sedimentation or flotation system provided?

- Lower SWRO stage cost: The potential for lower downstream cost, based on the better water quality achieved by the UF system, is a key aspect since the cost of the SWRO system typically amounts to a multiple (a range of 3-10 times) of the pretreatment cost. Lower capital cost, e.g., by higher operating flux in the SWRO.

- More sustainable, lower cost SWRO operation: The argument has also been made that ultrafiltration might reduce energy cost, membrane replacement cost and SWRO cleaning cost by producing water with lower fouling tendency.

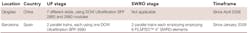

Table 2: Extended pilot trials have been carried out in Qingdao and Barcelona.

UF in Minimum Primary Treatment and Low Environmental Impact Schemes

DOW™ Ultrafiltration technology is based on a narrow pore size, pressurized vertical outside-in module configuration, which should provide the above-listed advantages for operation on minimum primary treatment and low environmental impact schemes. Therefore case studies of operational performance in pilot experiences and, more importantly, large scale plants employing this technology can contribute in assessing the potential for low primary treatment and environmental impact schemes.

Table 3: A summary of all operating experiences (excluding the Ghana plant which has not started yet) has been described by Busch et al. [2009], particularly in the context of low environmental impact and minimum primary pretreatment schemes. Qingdao trials have been reported in a focused report by Riaza et al. [2009]. Detailed performance data on the Wang Tan plant has been reported by Busch et al [2008]. A thorough review of the PengHu Magong plant results has been presented by Garcia et al [2009]. Operation information from the Cyprus plant has not been released yet.

Various SWRO desalination plants employing dual membrane systems have been designed by Dow Water & Process Solutions. All use minimum primary treatment schemes. Low environmental impact treatment schemes are used as well, although to different degrees.

Barcelona Pilot

The Barcelona pilot started operation in January 2009 with 2 parallel lines using DOW Ultrafiltration SFP-2660 modules. The water is taken from a 1 km long intake pipe, with an average turbidity of 2.5 NTU, average TSS of 7 mg/L and average SDI (75%) of 20 %/min.

The primary treatment is only a screening filter. Coagulation has not been employed.

The UF modules have operated in a sustainable manner at 60 L/h/m², using a backwash with air scour every 30 minutes.

The chemically enhanced backwash (CEB) operation was carried out every 6 to 48 hours for 30 seconds at double the operation flow, with 430 mg/L sodium hypochlorite (NaOCl). The sustainable frequency was 18 hours. These CEB conditions amount to a continuous equivalent dose of 0.4 mg/L.

Only two clean-in-place (CIP) operations were carried out in the ultrafiltration stage during the first 9 months of operation, using 2000 mg/L NaOCl and 1000 mg/L HCl, which results in negligible continuous equivalent concentrations of 0.02 and 0.01 mg/L respectively.

The UF permeate was sampled for transparent exopolymer particles (TEP).

The SWRO stage operated at a flux of 15 L/h/m² and exhibited a very high recovery of 52-53% with six 4040 elements in series. It was cleaned once between January 2009 and February 2010, which represents very reliable performance.

Summary and Conclusions

Primary treatments of all kinds have been and are continuing to be investigated, designed and built — from very extended (chlorination, pH adjustment, coagulation and flocculation in chambers, with coagulant and flocculent aid, followed by clarification) to very minimalistic (screen only).

The study of primary treatments shows that it is possible to operate integrated UF-SWRO systems with very reduced pretreatment consisting of only a strainer before the UF. The plants established with DW&PS technology have used only minimalistic pretreatment but have been able to provide reliable SWRO operation with good UF outlet quality, and have operated at the hydraulic design point, especially in the UF system, with acceptable cleaning frequencies.

In terms of low environmental impact schemes, the elimination of continuous chlorine dosing caused a significant reduction in NaOCl and sodium metabisulfite (SMBS) concentrations employed in SWRO plants – which is available for media and ultrafiltration pretreatments. Ultrafiltration offers the opportunity to significantly reduce or eliminate coagulation schemes (when ultrafiltration membranes with narrow pore sizes are used), which significantly reduces iron consumption and sludge generation.

Further research and development should focus on cost savings in the pretreatment stage and in the integrated system, based on credible input data, solid experimentation and cost models prepared in a transparent and credible manner.

References

Busch, M., Chu, R., Kolbe, U., Meng, Q.-Q., Li, S.-J., “Integrated Ultrafiltration and Reverse Osmosis Membrane System for Seawater Desalination – 1000 Days Field Experience with Dow™ UF and Filmtec™ Technology in the Wangtan Datang Power Plant.” European Desalination Society Conference, EUROMED series, Dead Sea, Jordan, November 2008. Desalination & Water Treatment 2009(10), p. 1-20.

Busch, M., Rosenberg, S., Chu, R., “Novel Trends in Dual Membrane Systems for Seawater Desalination: Minimum Primary Pretreatment and Low Environmental Impact Treatment Schemes.” IDA World Congress – Atlantis, The Palm – Dubai, UAE November 2009, Dubai, United Arabic Emirates, DB09-019.

García-Molina, V., Chang, R., Busch, M., “First Year Performance Review of Magong UF/RO Seawater Desalination Plant.” European Desalination Society Conference, Baden-Baden, Germany, May 2009.

Riaza, A., Shao, E., Busch, M., Suarez, J., Salas, J., Wang, D., “Performance of Outside-In Pressurized Ultrafiltration in Qingdao Pilot Test.” European Desalination Society Conference, Baden-Baden, Germany, May 2009.

About the Authors:

Markus Busch is the Global Application Development Leader - Desalination for Dow Water & Process Solutions. He can be reached at +49 7227 913751 or [email protected].

Robert Chu is a technical service specialist for Dow Water & Process Solutions in Asia Pacific. He can be reached at +86 2138511639 or [email protected]

Steve Rosenberg, Ph.D., is a scientist for Dow Water & Process Solutions. He can be reached at 952-838-3993 or [email protected].