Sulaibiya water reuse project well underway

By David Gagne, Guido Vaccaro

Construction of the world's largest membrane-based water reclamation facility is well underway in Sulaibiya, Kuwait, with 80% of civil works and 30% of mechanical and electrical installations completed. By the end of 2004, the full plant is expected to begin converting 100 mgd of municipal effluent to 85 mgd of high-quality reclaimed water that will be used for agriculture, providing an alternative source to potable water.

The consortium, including Mohammed Abdulmohsin Al-Kharafi & Sons of Kuwait (The Kharafi Group) and the US company Ionics, Incorp-orated won a 30-year concession from the Kuwait government in May 2001 to recover municipal wastewater from Kuwait City and the surrounding area. The contract allows the consortium to design, build, own, operate and maintain the 375-million litres per day (l/d) wastewater treatment facility near Kuwait City. Purified water from the Sulaibiya facility will be used for non-potable uses that are currently affecting the drinking water supply, by blending with brackish water to better exploit existing brackish water distribution facilities.

The team used well-proven processes to design the membrane-based water reuse plant. Municipal effluent is given preliminary treatment at Ardiya and then piped 25 km to the Sulaibiya facility. A conventional biological wastewater treatment plant treats the effluent to better than secondary effluent quality. Secondary effluent then flows to the water reclamation plant, which uses ultrafiltration (UF) and reverse osmosis (RO) to further purify the water for reuse. Sludge from the wastewater treatment plant is treated to allow for disposal by landfill, incineration, or by composting.

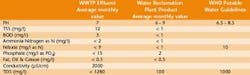

The water quality data used as the basis of design and projected treated water quality are detailed in Table 1. The plant influent is typical domestic sewage. The plant design average monthly value is 5 mg/l BOD and 10 mg/l TSS, considerably better than the original requirement of 20 mg/l BOD and 20 mg/l TSS. However, the water reclamation plant is designed to accommodate peaks in water quality due to upsets in performance of the treatment plant. The average total dissolved solids (TDS) in the feed is 1,280 mg/l, and the plant product will be less than 100 mg/l, significantly better than World Health Organization (WHO) potable water guidelines.

The Kharafi Group's extensive experience with constructing and operating sewage treatment plants in Kuwait was used as a basis for the wastewater treatment plant design. Preliminary treatment at Ardiya removes particulate, grit, oil and grease. The waste is then pumped to Sulaibiya. The wastewater treatment plant includes anaerobic, anoxic and aerobic systems for enhanced biological removal of nitrogen and phosphorus, plus secondary clarifiers. To minimise variation in flow, buffer volume was taken into account in the design of the facilities at Ardiya, the aeration basins and the clarifiers. Sludge treatment involves aerobic digesters and drying beds. This process is well-proven in Kuwaiti conditions, and was selected for low odour, low operation and maintenance costs, minimum sludge quantity for disposal, and the environmental benefit of being able to use the sludge as a soil conditioner or organic fertiliser.

The water reclamation plant will treat 375,000 m3/day (100 mgd) of secondary effluent, which will be prefiltered with disk filters and then fed to the ultrafiltration system. Ultrafiltration (UF) product feeds a RO plant, and UF waste is recycled to the wastewater treatment plant. The UF system will treat 100% of the flow after biological treatment since UF waste is recycled; hence the feed to the RO system is also 100 mgd. The RO plant is designed for 85% water recovery so the expected production rate is 85 mgd.

Membrane filtration pretreats the secondary-treated municipal effluent before being fed to the RO plant. Membrane filtration was selected over conventional tertiary clarification and filtration because it reduces plant chemical consumption and guarantees that low turbidity water is fed to the RO. Better quality pretreatment to the RO plant lengthens membrane life, lowers operating pressure, and reduces cleaning frequency for the RO system. Also, the combination of UF and RO removes bacteria and pathogens and provides potable quality water suitable for agriculture or groundwater recharge.

Bids for the membrane filtration system were solicited from major suppliers. After a thorough evaluation, UF technology from Norit was selected for its favourable life cycle costs and, since this is a UF membrane, for the better quality of water to the RO membranes. The UF plant will use Norit's X-Flow membranes, which are made of capillary hydrophilic hollow fibres. These membranes are packaged in 8" x 60" membrane elements that provide 35 m2 of membrane area per element. Four membrane elements are placed inside a membrane housing, and thirty-two membrane housings are installed in each UF unit. This plant consists of 68 skids, each with 32 membrane housings for a total of 8,704 membrane elements. The plant will be operated continuously and is fully automatic, with very little operator attention required.

UF units are operated individually

Each unit is backwashed regularly, whereby all suspended matter that is being retained by membranes is removed from the plant. The backwash water is pumped back upstream of the wastewater treatment plant to achieve the highest possible overall water recovery for the plant. Occasionally, a low dose of chemicals will be added during a backwash. This Chemically Enhanced Backwash (CEB) will remove any matter that may have adhered to the membrane surface and is not removed by a hydraulic backwash alone. Since the backwash and CEB actions are scheduled on an individual unit basis, taking only a minor section of the plant out of filtration mode, the continuous flow of effluent from the biological plant can be accommodated. The effluent fed to the UF first passes through a disk filter, after which a small amount of coagulant is added to coagulate fine particulates and possibly allow some TOC removal to facilitate the operation of the plant. The SDI15 of the UF product will be below 2, an important criterion for RO plant performance. Previous experience treating secondary municipal effluent with UF has shown that SDI values of less than 1 are possible.

The salinity of the municipal effluent has an average monthly value of 1,280 mg/l TDS, with a maximum value of 3,014 mg/l. RO will be used to desalinate the water to 100 mg/l TDS, and provide a second barrier to bacteria and viruses. RO technology is well proven for desalinating municipal effluent. The system will consist of 42 identical skids in a 4:2:1 array. Approximately 21,000 membranes will be required for this project. The RO system is limited to operating at 85% recovery and will be limited for this plant by calcium phosphate precipitation, which can frequently limit water recovery in membrane systems desalinating municipal effluent. The RO product will pass through a stripper to remove carbon dioxide to adjust pH with a minimum amount of caustic before distribution, and the product will then be chlorinated before leaving the plant. RO brine is disposed into the Persian Gulf.

Since this is a build, own, operate and maintain contract, the consortium will also be responsible for running the plant once construction is complete. The Kharafi Group will operate and maintain the wastewater treatment plant and Ionics will operate the water reclamation facility.

Summary

The Sulaibiya water reclamation plant will be commissioned in phases during 2004. The first phase should be commissioned in mid-2004, and the full plant is expected to be in operation by the end of 2004.The project uses proven technology for the wastewater treatment plant and for the water reclamation facility. A combination of UF and RO technology will provide bacteria, virus and TDS removal, producing water that meets potable water quality standards. This project is expected to provide the benchmark and catalyst for the successful implementation of similar build, operate and transfer (BOT) projects to increase potable water supplies in the Middle East region.

Authors' NoteDavid Gagne is the project manager at Ionics, Incorporated, based in Watertown, Massachusetts, USA. Guido Vaccaro works for Italba S.p.A, located in Milan, Italy.