Reducing Middle East water and power station costs

By Daniel Hoffman, Amnon Zfati

Part Three--A wide range of plant designs and schemes can reduce costs and mismatch problems in Middle East dual-purpose stations.

A wide range of plant designs and schemes can reduce Middle East water and/or power cogeneration costs and minimise or even eliminate demand mismatch problems.

All these designs and schemes reduce the dependence of water production on external (i.e. non desalination plant) power demand by increasing the cogeneration stations' water to power output ratios (W/P) in one or more of the following methods:

• Increasing the thermal desalination plants' gained output ratios (GORs);

• Forming hybrid plant schemes with other types of electric power consuming desalination plants; and

• Changing the mix of power plants and/or increasing their heat recovery to make more cogenerated steam available per KWh.

Fifteen such plant designs and schemes were presented and examined within a comprehensive study sponsored by the Middle East Desalination Research Center (MEDRC) in Muscat, Oman.

Distillation plants with higher GORs

Three alternative distillation plants with higher GORs were examined.

Increasing MSF plants' GORs and outputs by incorporating nanofiltration (NF) feed pre-treatment and raising the plants' top brine temperatures (TBTs) and recovery ratios. Cost calculations show that this solution is uneconomical. It is preferable to increase the GORs of existing MSF plants during low power demand periods by operating them at their maximum safe continuous TBTs and decreasing recycle flows to their design limits. New MSF plants' GORs can be raised with conventional designs and materials of construction to the same GORs projected for the NF/MSF scheme without exceeding current TBT limitations. The higher TBTs of the NF/MSF scheme require use of higher-cost corrosion-resistant materials, higher-cost higher-pressure cogenerated steam and stiffer evaporator vessels that can withstand these pressures.

Use of efficient low-temperature multi-effect distillation (LT-MED), or low-temperature thermal vapour compression (LT-TVC), or LT-MED/TVC plants combined with low-pressure BPSTs. Horizontal-tube, falling-film LT-MED plants, using proven low-cost materials of construction and operating with low-cost 0.4 bar BPST steam at TBTs of 70 0C, GORs of up to 10:1 and electrical energy consumptions as low as 1.2 Kwh/m3, are commercially available today. LT-TVC plants of similar design, operating with thermo-compressors on 2 to 3 bar steam, have GORs of up to 13:1. Each type of plant offers lower water costs and higher W/Ps than currently used Middle East MSF plants.

The preferred use of the LT-MED and LT-TVC technology, however, is in a scheme that combines LT-TVC/LT-MED plants with low-pressure back-pressure steam turbines (LP-BPST). This arrangement enables operating the distillation plants in their high-GOR LT-TVC mode when power demand is low and cogenerated steam is in short supply and operating them in their lower-GOR LT-MED mode when power demand and cogenerated steam availability are high. Power sale revenues from operating the LP-BPST during peak power demand periods significantly improve overall economics.

Use of advanced-design ultra high-efficiency high-temperature multi-effect distillation (HT-MED) plants. A team of Israeli and US engineers designed and pilot plant-tested large novel, vertical-tube, falling-film HT-MED plants with 24 to 32 effects, operating with 1.4 to 1.6 bar cogenerated steam at a TBT of 1100C and GORs of 20:1 to 24:1. Projected water costs from these plants are as low as those from hybrid SWRO plants and their high W/Ps will enable their operation in all Middle East dual-purpose stations only with cogenerated steam.

Other hybrid thermal/electrical desalination plant schemes

Three other hybrid thermal/electrical desalination plants schemes were examined.

Topping thermal plants with mechanical vapour compression (MVC) distillation units. MVC distillation units provide an alternative to SWRO as electricity-consuming components within hybrid thermal/electrical desalination plant schemes. MVC plants are less sensitive to seawater turbidity and contamination than SWRO plants, requiring only minimal feed pretreatment. Their product quality, at less than 5 ppm TDS, is also superior. Their specific investments and electrical energy consumptions are higher, but the loads created by the higher specific energy consumptions will result in larger quantities of cogenerated steam per m3 of MVC plant product.

MVC plants would tie-in perfectly, from the point of view of temperature and compatibility of materials, as separate topping sections to MED plants. The MVC plants would receive deaerated and pre-heated feed from the MED plants' top temperature groups of effects and return their hot brine and product streams to the MED plants' brine and product flash channels. The feed heat exchangers and the non-condensable gases removal subsystems, that are significant cost elements in stand-alone MVC plants, are thus eliminated, and result in overall savings in seawater supply and brine disposal costs.

Combined MVC/MED and MVC/TVC plants. MED plants that combine mechanical vapour compressors (with suitable disconnection valves) across one or more groups of effects, and TVC plants that combine, interchangeably (also with suitable disconnection valves), both mechanical and thermal vapour compressors, offer a versatile and flexible means for dealing with power and water demand mismatch situations. The MVC/MED and MVC/TVC combined plants would be operated in their MED and TVC modes, respectively, when power demand and co-generated steam supply are sufficient, and in their MVC modes when power demand is low, cogenerated steam supply drops and low valley period TOU power tariff rates can apply. The major components of the plants' investments, the evaporator sections with all their ancillaries, can thus be used year round and only the mechanical and thermal compressors will be idled periodically.

Low-cost MVC and/or SWRO plants for intermittent operation. If SWRO and/or MVC desalination plants are to be added to cogeneration stations and operated only intermittently to produce additional water and increase cogenerated steam output, then such plants should benefit from special designs that reduce investments (and capital recovery water cost components) and/or allow high short-term outputs. This could be economical even if such reductions are at the expense of higher specific electrical energy consumptions (to be charged at low valley period TOU tariff rates), higher salinity product water (that will be blended with thermal desalination plants' 0-20 ppm TDS product water) and higher maintenance costs. The MEDRC study examines and presents some ideas for such special designs.

Power plant-related solutions

Two power plant-related solutions were examined.

Improving the mix of power plants. The study recommends that the power plant mix and scheme presented in Part 2 of this article be adopted in new cogeneration stations, and approached in existing cogeneration stations, by replacing aging power plants with new suitable plants. The rationale and quantitative justification for this scheme and its recommendation are brought out through two tables in the study that examine the relative economics of supplying the thermal desalination plants' steam requirements during power and water demand mismatch situations with all the dual-purpose power plants examined in the study, with and without considering power production costs. The tables confirm that lowest cost steam and power, by significant margins, will be cogenerated with GT/HRB/BPST combined cycle power plants, exhausting steam at 0.4 bar.

Increasing power plant heat recovery through use of a special flue gas cooler. Two schemes for recovering additional low-grade heat from power stations are examined in the study. Both are based on the use of a special flue gas cooler constructed from plastic materials and capable of withstanding the severe corrosive conditions existing when the flue gases (from power plants using liquid fuels with a sulphur content) are cooled below the sulphuric acid dew point. The additional heat extracted can be used to produce economically with an LT-MED plant alone more desalinated water or, by adding an auxiliary LP-BPST, both water and electricity, improving the station's W/P ratio.

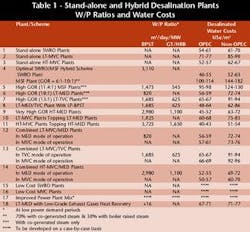

Table 1 summarises and compares the water costs and W/P ratios of the eighteen stand-alone and hybrid desalination plant designs and schemes examined in the study. The table shows that the potential for water costs reduction is from the current range of 1.0-1.4 US$/m3 to 0.5-0.7 US$/m3 in the OPEC countries, and from 1.4-1.8 US$/m3 to 0.6-0.9 US$/m3 in non-OPEC countries.

In addition, the table shows that the lowest cost water using currently available technologies will be derived in new dual-purpose stations with hybrid LT-MED/SWRO plants driven by the study's preferred power plant mix, and in existing stations, where only 2-3 bar cogenerated steam is available, with hybrid LT-MED/TVC/SWRO plants combined with LP-BPSTs.

Authors noteDaniel Hoffman and Amnon Zfati of ADAN Technical & Economic Services Ltd., Tel Aviv, Israel, highlighted the main points of their MEDRC-sponsored study in this three-part series published in WWI. Part 1 (WWI April) analysed the reasons for high desalinated water costs in Middle East countries' dual-purpose stations. Part Two (WWI May) discussed a hybrid seawater reverse osmosis (SWRO) and thermal desalination plants scheme that can reduce power cogeneration costs and minimise or eliminate demand mismatch problems. The full study may be downloaded from MEDRC's web site: www.medrc.org.om, by clicking on "Research Program", then on "Final Reports", and, finally, on Project No. 97-AS-008a.